Dan Dubeau

Ultra Member

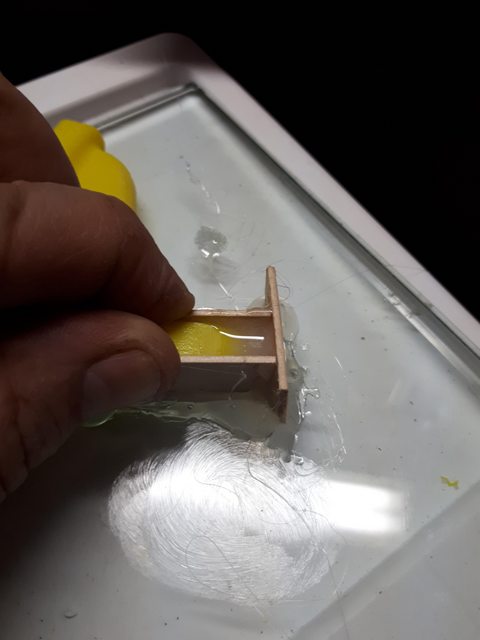

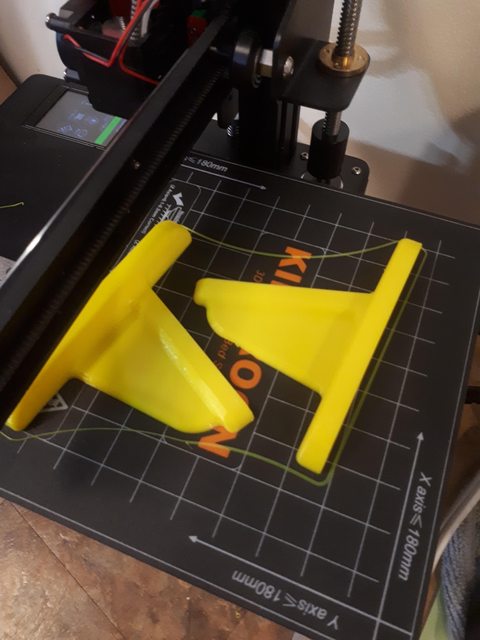

Had a good day tooling around in the shop. Machined another brand on the CNC for the Wifes business logo (figured out a MUCH quicker and cheaper way to program and cut these), and designed, 3d printed a pattern, and cast a part to try out a new process. The part is complete shit, but it was a good test. The pattern was printed fast (0.3mm layers) and had ZERO prep work, just straight off the print bed and into the sand. The results show. I just wanted to test to see how much I could get away with. I need to cast 11 more of these, so will try and improve the results a bit more.

![1joiCKFl.jpg]()

![E1tIIaFl.jpg]()

![sM8eFowl.jpg]()

![v4CXotGl.jpg]()

![otzgcNjl.jpg]()

I haven't cast anything in 2 years, so it was pretty fun to get back to it again. I have a lot of projects in the works that will benefit from casting and 3d printed patterns, so I'm trying out some things and experimenting with some ways of doing it a bit faster, while giving up a bit of "perfection". This is just a bracket for some TTS toolracks.

I haven't cast anything in 2 years, so it was pretty fun to get back to it again. I have a lot of projects in the works that will benefit from casting and 3d printed patterns, so I'm trying out some things and experimenting with some ways of doing it a bit faster, while giving up a bit of "perfection". This is just a bracket for some TTS toolracks.