Telling my dad about this thread and we had a good conversation about fixing old row boats. We, like everyone on this thread at one time or another had an aluminum boat, I think we had a 9hp motor, not sure it’s been 40 years. But we really enjoyed it. Lots of lazy fishing discussing the world’s problems, that of course we could solve so easily.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Solid Rivets

- Thread starter djberta

- Start date

Tool

I have lots of soft steel and aluminum rivets. Mainly solid with some hollow, 1/4” dia and smaller.

Also have a 1/4 » rivet set

I’ve had them for years and have used them twice

Any interest?

We, like everyone on this thread at one time or another had an aluminum boat, I think we had a 9hp motor, not sure it’s been 40 years.

Yup, count me in. One year I took my boat north and installed solid rivets on many of the seams and also installed two new ribs to stop the nose section from oil drumming whenever we plowed into a wave...... Great times!

The help in this thread alone has been amazing. Me and the wife are almost done selling our Leduc house. One more run to finish moving on Monday and possession for the buyers is Friday. Next weekend will be the first free weekend I have had in almost a year. Still have lots of work in Airdrie on the house and organizing my mountain of stuff. Then maybe I can get out and do a shop visit with a member and good how to on the rivets.

Nice collection. Your in BC?I have lots of soft steel and aluminum rivets. Mainly solid with some hollow, 1/4” dia and smaller.

Also have a 1/4 » rivet set

I’ve had them for years and have used them twice

Any interest?

I have a single Drawer in a parts cabinet with a mess of assorted rivets. I figure it amounts to about every second year I actually look there for a solution.I have lots of soft steel and aluminum rivets. Mainly solid with some hollow, 1/4” dia and smaller.

Also have a 1/4 » rivet set

I’ve had them for years and have used them twice

Any interest?

Projects that need a bunch of rivets tend to be worth buying the right size for, and if you only need one, you can form a head on both ends of some clean rod stock.

finally got a chance to put every thing together with the rivets. My take away. Less is more when using the air river tool. Also use the right drill and length of rivet. Even with my best effort I was all over the place with the rivets. I think I was driving them at weird angles. Any ways the back splash is done just need to mount it. Used some scrap stainless I had and some aluminum I had in my junk pile. I will definitely not win any awards for the riveting but it is all together and I can use that experience in doing my Christmas project for my dad.

finally got a chance to put every thing together with the rivets. My take away. Less is more when using the air river tool. Also use the right drill and length of rivet. Even with my best effort I was all over the place with the rivets. I think I was driving them at weird angles. Any ways the back splash is done just need to mount it. Used some scrap stainless I had and some aluminum I had in my junk pile. I will definitely not win any awards for the riveting but it is all together and I can use that experience in doing my Christmas project for my dad.My training in running either end of a solid rivet (bucking bar, or Rivet gun) tells me that it takes a fair bit of experience, to get anything like a consistent result.View attachment 55903finally got a chance to put every thing together with the rivets. My take away. Less is more when using the air river tool. Also use the right drill and length of rivet. Even with my best effort I was all over the place with the rivets. I think I was driving them at weird angles. Any ways the back splash is done just need to mount it. Used some scrap stainless I had and some aluminum I had in my junk pile. I will definitely not win any awards for the riveting but it is all together and I can use that experience in doing my Christmas project for my dad.

Sorta like the kid who asked a guy on the streets how he could get to Carnegie Hall.... "Practice!"

We drove, quite literally, thousands of rivets, during our training and practical sessions. Some were ugly!

TorontoBuilder

Sapientia et Doctrina Stabilitas

been a while since I heard someone else mention the societySort of. SCA.

Several of my friends are still a part of it. But not I.mention the society

TorontoBuilder

Sapientia et Doctrina Stabilitas

Like so many other hobbies that died when I got married this one too went by the wayside for meSeveral of my friends are still a part of it. But not I.

been a while since I heard someone else mention the society

Been there. Have a T-shirt and a peerage. And some scraps of armor.been a while since I heard someone else mention the society

Best rack I ever had to hang my hobbies off of.

You mileage will likely vary.

Hello DJ,

I have some experience with steel rivets, 3/8, to 3/4" sizes for architectural metal

We made domed rivet sets one to hold and the other to form the head. We inserted the rivet heated the blank end and used the press. Nicely formed consistent button each time

The trick is to get the right length.

You can also tack weld them if you only see the one side. Trim or grind the stub as required

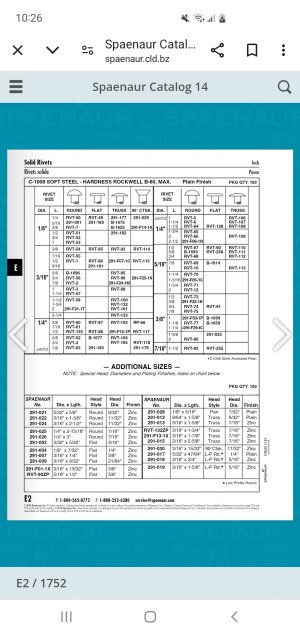

We bought them from Spaenauer. See atattchment

Best,

I have some experience with steel rivets, 3/8, to 3/4" sizes for architectural metal

We made domed rivet sets one to hold and the other to form the head. We inserted the rivet heated the blank end and used the press. Nicely formed consistent button each time

The trick is to get the right length.

You can also tack weld them if you only see the one side. Trim or grind the stub as required

We bought them from Spaenauer. See atattchment

Best,

Attachments

Had not thought about welding the back side. I got the rivets off amazon. Its good I got a multilength set. As there was a couple spots on the corners that needed longer then I would have thought rivets.Hello DJ,

I have some experience with steel rivets, 3/8, to 3/4" sizes for architectural metal

We made domed rivet sets one to hold and the other to form the head. We inserted the rivet heated the blank end and used the press. Nicely formed consistent button each time

The trick is to get the right length.

You can also tack weld them if you only see the one side. Trim or grind the stub as required

We bought them from Spaenauer. See atattchment

Best,