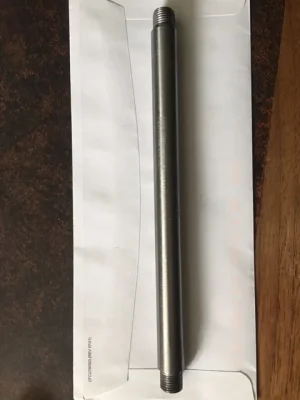

Can this O1 oil hardened drill rod be threaded without annealing it first?

It arrives in the annealed state ready for machining. Heat treating, if you choose, comes after.

Can this O1 oil hardened drill rod be threaded without annealing it first?

I gotta be honest, your wording and tone comes across very accusatory and condescending. I'm obviously a newbie trying to explain this. Why not help a guy out rather than come across in a condescending fashion?PEr my last response to you, I had posted the schematic earlier in the thread. Since you didnt seem to notice this, here it is again

Yes actually, I did notice the diagram. Even without the parts unidentified, I think I understand the distinction & purpose of spacers, bearings and nuts. What was confusing was your description. Apparently all the components are 'at the end of shaft'. Early on I thought red arrow parts might be bushings integral to the end of the drum & possibly a typo. Exploded views are nice but don't show parts in-situ. It may be obvious to you but not to someone else. Good luck with your project.

There are identical bearings at each end of this shaft with an id that is a slightly loose press fit. So the two drums slip fit on the shaft and two spacers are added, one at each end of the shaft. The two nuts thread on at each end of the shaft until it draws the bearings, spacers and drums together tightly to rotate with the rotation of the shaft

I dont understand where threaded rod could be used here.You can get threaded rod at PA. Cheap too. I got it at 50% off on sale.

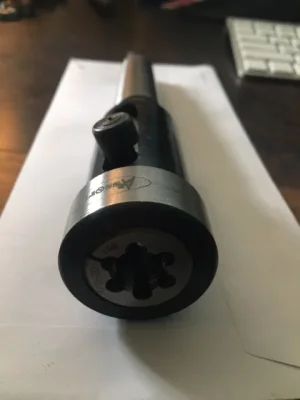

I made multiple pull rods for my mills. The trick is to thread not single point - as the thread is small and speed would need to be fast - but just place the rod in the collet in the tailstock and place the die in the chuck. Run forward, run reverse - done. Takes like few minutes.

12" is quite short, you don't have to worry too much about the part whiplash too much - for longer stuff you need a follow rest for sure or similar setup.

Overall to make a new part like on picture from some scrap I have to precise dimensions is like maybe 2h. Maybe faster if in race mode 😉 To weld and fix probably over an hour, maybe 2 as well. If its a wear part and you expect to go through multiples, make 2, will take a bit longer then 1, maybe 3h.

I dont understand where threaded rod could be used here.

The shaft finished OD is supposed to be 15mm +/- some small tolerance. 3/4" on each end needs to be turned down to 1/2" and threaded for 1/2-20 (or 1/2-13 as janger suggested). Thats it.

I cant imagine this is a 2 hour job per shaft, is it?

The entire rod doesnt need to be cut down to 15mm. The 15mm nominal size of teh 'ground drill rod' out of the box works (apparently). Just the ends need to be turned down and threaded.

I gotta be honest, your wording and tone comes across very accusatory and condescending. I'm obviously a newbie trying to explain this. Why not help a guy out rather than come across in a condescending fashion?

Or use a touch of green loctite (wicking grade) and a star lock washer. Just enough hold to prevent it from backing off.If you don’t have a left hand threading die you could just drill it for a pin.

You did well , those are nort of $400.00 on the Snapon truck , I have the same setI picked up this on kijiji used for $100 last year, so not a problem. Of course I've already had to buy 3-4 dies that werent in the set for odd sizes. I got tired of junky T&D sets with poor quality tap and die handles, etc. This set is vastly superior in quality to the cheapies I've owned in the past.

View attachment 20278

I ended up using a 'floating' tailstock die holder to do the threads instead of single point threading them.

Which die holder did you get?

View attachment 21781View attachment 21782

The MT3 taper needed to be 'set' in the tailstock quite firmly for it not to spin while threading. This was one of teh screwups I encountered. Also, I should have remembered to chamfer the ends of teh shaft after turning the shoulders down to allow the die to bite in more easily. Lessons learned for next time.

I

I confess that I am shocked that it spun. Usually tapers with the tang tip do not (actually can not) spin except for a few degrees when the tang catches.

And before anyone jumps on me, yes I know that's not the purpose of the tang nor good practice, nor would I ever use it that way.

It is just that I am shocked and find myself wondering how that is possible.