@jcdammeyer and

@Degen Thanks for the input.

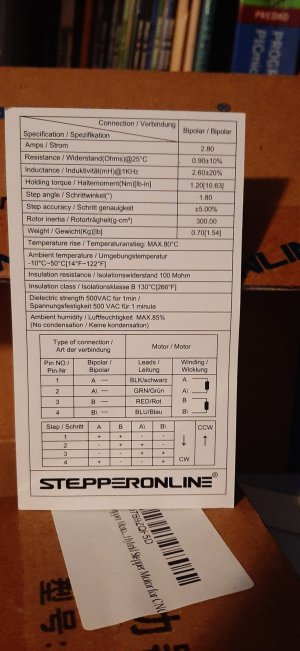

In post #3, I show the procedure I used to determine the torque required. Not too scientific but figured it was a start. As commented, the motors I had in stock were about 170 oz (actually 178 oz) motors and so I was going to be borderline. But, seeing as learning the Arduino code and trying to recall programming skills from many years ago, this whole project was an adventure/gamble, for me.

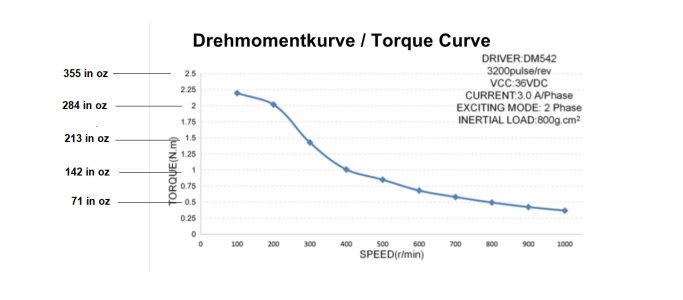

Fast forward to post #31 and the motor was pretty much exactly as expected. It would move along, then skip, idle, pulse. I could put a slight bit of pressure on the crank and it would pick up again. But at least the electronics was working out so I looked for the largest motor I could find in a NEMA23 mount and came up with this one. There was higher torque, but my controller only went to 4 amps or so, and I figured at 2.5 x the one that was borderline, it would be adequate.

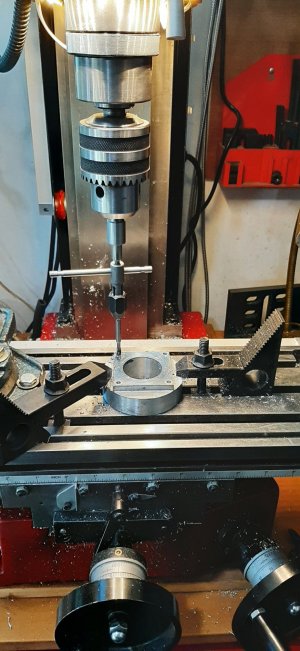

At 425 ozin, I thought it was quite a step up. As expected the mount was perfect, being a 23. I drilled out the coupling mount to accommodate the larger motor shaft size, rewired the new motor in, this time incorporating a connector instead of directly wired to the control box.

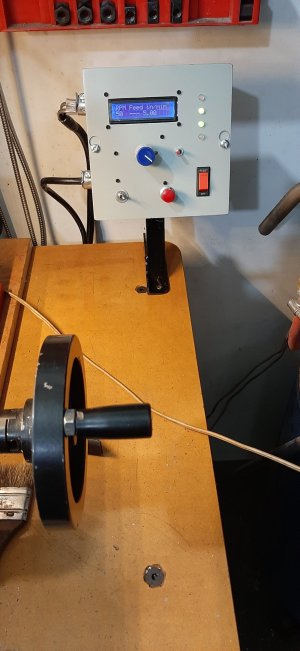

Seems to work well now. If you watch the video closely, you might pick up a slight hitch once per RPM. This is when the controller paints the display. I might rework the code to see if I can reduce the write time, but at a higher pulse rate, it should not affect the milling.

As to the feed vs RPM, my mill x lead screw is 0.100"/revolution. I just went with that. The display, due to the math, only shows even RPMs, but the feed rate is variable between. It would be an excuse to continue looking at the code to see how to display the speed with a higher resolution. In my shop, with this small mill, not necessary, but it would just be an exercise in learning. As is, it spins up to about 120 rpm, iirc. I played around with the pulses setting on the controller to find one that yielded an adequate top end, yet smooth "enough". 800 pulses/step seemed to be the magic one. The "top end" is really only used to position the table. I have never really paid much attention to feed rates before, despite reading them. I went by finish, chatter, etc. I don't think these small mills can do the feed rates/depth of cuts that engineering books suggest for the proper cut. ie, If my DOC was 0.120", as recommended yesterday for a cut, I would either break the mill or the motor would just stop. Having said that, now that I have a convenient feed display and consistent feed rate, I will be able to explore those settings more.

I should clarify, the motor spec sheet is the old motor and the chuck is coupling that was being modified for the new motor.

Thanks for the interest.