-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your shops!

- Thread starter slow-poke

- Start date

So here are a few shots of my shop.

The tractors belong inside, but the wedding this past fall screwed that up. No room inside right now.

I didn't take photos of the tractor parking areas. They are just boxes and stacks of stuff put there temporarily.

I thought I'd start the inside tour with a shot of my electronics work area up on the mezzanine. I used to think I had a lot of electronics equipment, but after seeing @slow-poke's, I think my stuff is pretty bland. I can't turn stuff on like he did either.

My soldering station is on the left. On the right are work surfaces made from inexpensive plywood and/or 2x12s on boxes. I have several projects on the go there now. There is also other stuff on a storage rack. I normally have my drafting board where I am standing to take the photo, but I had to move it out of the way or I couldn't get a good photo.

Above is my metal shop working area. The lathe is on the right. To the left of it and behind my mill is a long rolling cabinet for lathe tooling. It is easy to just turn around to work on the lathe or to work on the bench.

My mill is beside the lathe bench and it faces another work bench on the right for my big vise, grinder, and drill press. My surface grinder is back to back with the mill.

It's easy to work in the area because you don't have to walk far and there is always a workspace available just by turning around or walking a few feet between machines.

Last, but not least, above is my break room. Before you get all jealous, keep in mind that this isn't normal at all. Usually, it's packed jamb full with in-process projects on the counters and tables, 11 big planter units, seed bags, reference books, farm chemical storage, and repair parts. But I had to clean that all out for the wedding. In fact, it's so clean and tidy in there right now that it's actually downright embarrassing. To be honest, I'm ashamed of it. Sorry about that......

The tractors belong inside, but the wedding this past fall screwed that up. No room inside right now.

I didn't take photos of the tractor parking areas. They are just boxes and stacks of stuff put there temporarily.

I thought I'd start the inside tour with a shot of my electronics work area up on the mezzanine. I used to think I had a lot of electronics equipment, but after seeing @slow-poke's, I think my stuff is pretty bland. I can't turn stuff on like he did either.

My soldering station is on the left. On the right are work surfaces made from inexpensive plywood and/or 2x12s on boxes. I have several projects on the go there now. There is also other stuff on a storage rack. I normally have my drafting board where I am standing to take the photo, but I had to move it out of the way or I couldn't get a good photo.

Above is my metal shop working area. The lathe is on the right. To the left of it and behind my mill is a long rolling cabinet for lathe tooling. It is easy to just turn around to work on the lathe or to work on the bench.

My mill is beside the lathe bench and it faces another work bench on the right for my big vise, grinder, and drill press. My surface grinder is back to back with the mill.

It's easy to work in the area because you don't have to walk far and there is always a workspace available just by turning around or walking a few feet between machines.

Last, but not least, above is my break room. Before you get all jealous, keep in mind that this isn't normal at all. Usually, it's packed jamb full with in-process projects on the counters and tables, 11 big planter units, seed bags, reference books, farm chemical storage, and repair parts. But I had to clean that all out for the wedding. In fact, it's so clean and tidy in there right now that it's actually downright embarrassing. To be honest, I'm ashamed of it. Sorry about that......

Oh oh. Green tractors. I live in red tractor land.So here are a few shots of my shop.

View attachment 56443

The tractors belong inside, but the wedding this past fall screwed that up. No room inside right now.

I didn't take photos of the tractor parking areas. They are just boxes and stacks of stuff put there temporarily.

View attachment 56430

I thought I'd start the inside tour with a shot of my electronics work area up on the mezzanine. I used to think I had a lot of electronics equipment, but after seeing @slow-poke's, I think my stuff is pretty bland. I can't turn stuff on like he did either.

My soldering station is on the left. On the right are work surfaces made from inexpensive plywood and/or 2x12s on boxes. I have several projects on the go there now. There is also other stuff on a storage rack. I normally have my drafting board where I am standing to take the photo, but I had to move it out of the way or I couldn't get a good photo.

View attachment 56431

Above is my metal shop working area. The lathe is on the right. To the left of it and behind my mill is a long rolling cabinet for lathe tooling. It is easy to just turn around to work on the lathe or to work on the bench.

My mill is beside the lathe bench and it faces another work bench on the right for my big vise, grinder, and drill press. My surface grinder is back to back with the mill.

It's easy to work in the area because you don't have to walk far and there is always a workspace available just by turning around or walking a few feet between machines.

View attachment 56433

Last, but not least, above is my break room. Before you get all jealous, keep in mind that this isn't normal at all. Usually, it's packed jamb full with in-process projects on the counters and tables, 11 big planter units, seed bags, reference books, farm chemical storage, and repair parts. But I had to clean that all out for the wedding. In fact, it's so clean and tidy in there right now that it's actually downright embarrassing. To be honest, I'm ashamed of it. Sorry about that......

There's one other problem, with so much steel and iron concentrated so close together, it's creating a gravity well and warping time and space.@Mcgyver - the only problem I see in your shop is that there are only 3 tires on the top shelf. Its driving my OCD crazy.... 2 or 4 not 3 unless you tell me you have a 3 wheeler.

I like the little cylindrical grinder you got, do you use it much?Miniature JS cylindrical grinder

My shop is a work in progress ATM. So it's pretty clean ATM. Don't have current photo when I get home from pre Christmas activities I'll shoot some pictures of my garage and up to date photo of shop. 41'x61' so I could have true 40x60 shop lol. Also max span before I had to use commercial trusses.

I got a deal on some 22" I beams so I cut them in half and gonna give them a forever home in the floor of shop so I can weld stuff to floor. I got 2 beams in every bay.

I would love to install gantry crane in shop but probably gonna just build Jib crane for forklift.

Any suggestions I can add to floor that maybe handy let me know I pour concrete on Jan 30th. So some time for last minute additions 🙂

I can always anchor bolt stuff like that into the walls and haven't really had to much issue with that. Can usually push crap in with equipment and round stock. But I could weld lifting lugs on I beams if the need arises.Anchor points for winching in the heavy stuff.

Front, back and both sides and with a couple of snatch blocks you can move stuff anywhere with little fear of tipping.

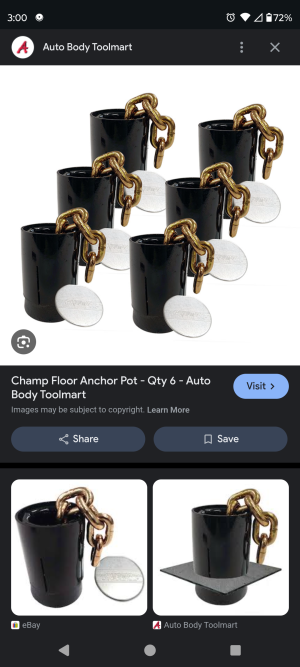

You did remind me I bought 2 of these floor anchors at a garage sale I should toss in floor at end of bay centered on beams.

Attachments

Insulation.I like the little cylindrical grinder you got, do you use it much?

My shop is a work in progress ATM. So it's pretty clean ATM. Don't have current photo when I get home from pre Christmas activities I'll shoot some pictures of my garage and up to date photo of shop. 41'x61' so I could have true 40x60 shop lol. Also max span before I had to use commercial trusses.

View attachment 56450

I got a deal on some 22" I beams so I cut them in half and gonna give them a forever home in the floor of shop so I can weld stuff to floor. I got 2 beams in every bay.

View attachment 56451

I would love to install gantry crane in shop but probably gonna just build Jib crane for forklift.

Any suggestions I can add to floor that maybe handy let me know I pour concrete on Jan 30th. So some time for last minute additions 🙂

Dan Dubeau

Ultra Member

Here's a quick look around my stuffed single car garage shop.

It's been an evolution over the past couple years to get this organized to the point that everything is now operational, and functional. Always a work in progress, and a wish list a mile long.

I've spent the last couple days cleaning up and finishing putting the Tormach back together. It's all operational now, I'm just waiting for some Trimsol coolant to come so I can fill the sump and get it chewing on some stuff. Still a bunch more cleaning up and putting stuff away to do after a couple months of neglect. Doesn't take long to pile up a bunch of stuff everywhere and jam up the whole works to where you can't do anything. I am still struggling with finding homes for all of my old job tools, and need to take some time to go through stuff and sell a bunch of duplicates. I don't think I need 5 boxes of 1/8" thick parallels anymore lol...... same with mics.....

It's been an evolution over the past couple years to get this organized to the point that everything is now operational, and functional. Always a work in progress, and a wish list a mile long.

I've spent the last couple days cleaning up and finishing putting the Tormach back together. It's all operational now, I'm just waiting for some Trimsol coolant to come so I can fill the sump and get it chewing on some stuff. Still a bunch more cleaning up and putting stuff away to do after a couple months of neglect. Doesn't take long to pile up a bunch of stuff everywhere and jam up the whole works to where you can't do anything. I am still struggling with finding homes for all of my old job tools, and need to take some time to go through stuff and sell a bunch of duplicates. I don't think I need 5 boxes of 1/8" thick parallels anymore lol...... same with mics.....

Attachments

Like your start.I like the little cylindrical grinder you got, do you use it much?

My shop is a work in progress ATM. So it's pretty clean ATM. Don't have current photo when I get home from pre Christmas activities I'll shoot some pictures of my garage and up to date photo of shop. 41'x61' so I could have true 40x60 shop lol. Also max span before I had to use commercial trusses.

View attachment 56450

I got a deal on some 22" I beams so I cut them in half and gonna give them a forever home in the floor of shop so I can weld stuff to floor. I got 2 beams in every bay.

View attachment 56451

I would love to install gantry crane in shop but probably gonna just build Jib crane for forklift.

Any suggestions I can add to floor that maybe handy let me know I pour concrete on Jan 30th. So some time for last minute additions 🙂

Definitely insulation under slab. If you’re a prairie person, at least four inches of high compression foam. Al least two inches foam on outside of grade beam down three to four feet under grade. Put in pex for radiant heat even if you’re not sure you’ll use it. If you have an idea where bigger tools will be, dig a hole for at least one ton jib foundations 12’ arm- maybe two? Much easier to do now. And you can add them later if and when they come up at auction.

What are you doing for electric?

Lots of other ways I can spend your money, but thats a start. ;-)

Rebar is already tied and beams leveled lol so no foam and foam is about 8k ish for high density foam 2". I did think about it but the municipality I'm in requires additional stuff to have it. When I built the house I lucked out on bunch of 4" roofing foam for cheap.Like your start.

What are you doing for electric?

I got a rough neck heater I'm gonna heat the shop with from the outdoor wood boiler.

Only got single phase in my area and doing 200 amps I got a 7.5 hp 600v RPC and some VFDS. I got 15hp motor I want to add to RPC or got another 7.5hp I can add depending what power demands I end up needing.

I plan on putting in footings for jib crane on outside wall between my 14' doors for unloading trailer or other activities.

For inside I may put some small jibs lagged to walls for lathe anyways. but in long run I'll probly build a gantry crane system in one or 2 of the bays as 20' span is more reasonable to build a crane for then 40'

It's hard to plan long term when I've only started collecting machines and have a few more on the list I want to find. only being 30 I got lots of time to upgrade and change stuff so it's hard for me do fairly permanent stuff when I don't have a clue what I'll end up with and how I want to use it persay. I Have an idea but who knows my life is semi dynamic.

That and adding a jib crane if I wanted I can just use bigger base and some other work arounds to make it happen if I did want a jib crane later on.

historicalarms

Ultra Member

I know what the light switch is for in the first two photos and the vise in the last one !!!Full set of show your shop...

The last two are especially for Susquatch, becuase everyone needs a little chaos, with a sprinkle of swarf on the mill table for good measure!

View attachment 56381View attachment 56380View attachment 56384View attachment 56382View attachment 56386View attachment 56387View attachment 56388View attachment 56389View attachment 56385View attachment 56379View attachment 56378View attachment 56383

Insulation.

Just got to put in walls so got that covered 😉

My current garage setup which I quickly out grew.

Elektrishun

Ultra Member

Messy or not some amazing shop images! I would risk tripping over stuff to see some of those tools up close and personal-wow!

If slow-poke and ChazzC ever sale off their test lead collections it will be like when the Russians flooded the market with potash. Maybe then some of us will be able to afford a few extra test leads for our shops...

I would attempt a quality video tour like ChazzC produced but I was once told I have a face for radio and a voice for silent movies. So still images it will be...

Warning - first image has a photo circled in yellow which I included because some of the guys were complaining about nobody having any "provocative" images in their shop. If it's too much I will remove it.

In the above image to the left of the beloved family cat photo is a certificate that I am most proud of given to me by my children. It is a certificate from the Reid Mental Institution that states I do not have Donkey Brains. For those who are fans of It's Always Sunny in Philadelphia you will appreciate that.

Images 2 and 3 below I'd like to point out the gym area which moves out of the way for vehicle repair. I do a little body work in that area, too. Right now I am trying to restore the body of a Retired Electrician. Not going great, needs a lot of work, probably should just part it out...

The plant you see in the image below belongs to my wife. Unfortunately it is not only surviving it is thriving. Can't eat it, can't smoke it, not sure what it does. Sacrifices we have to make for peace on earth.

I try to keep sensitive equipment protected and dust free as much as possible. The filing cabinet in the image below has been converted into an electronics work station where everything can be packed up and rolled out of the way. Notice how the second door from the bottom becomes a work table when open. Once this hack gets out I am sure the calls from SpaceX will be coming in.

Below are some other electronic test equipment. Again, put into cases for protection mainly from dust. I buy cases from Canadian Tire and Princess Auto when they go on sale. They are almost always on sale.

If I can offer any advice about planning a shop is don't forget the safety.

Fire extinguisher, eye wash station, first aid kit, carbon monoxide detector, increased air exchange when needed (I have a 2 speed exhaust fan), somebody who cares enough to come looking incase you don't come in for supper...

If slow-poke and ChazzC ever sale off their test lead collections it will be like when the Russians flooded the market with potash. Maybe then some of us will be able to afford a few extra test leads for our shops...

I would attempt a quality video tour like ChazzC produced but I was once told I have a face for radio and a voice for silent movies. So still images it will be...

Warning - first image has a photo circled in yellow which I included because some of the guys were complaining about nobody having any "provocative" images in their shop. If it's too much I will remove it.

In the above image to the left of the beloved family cat photo is a certificate that I am most proud of given to me by my children. It is a certificate from the Reid Mental Institution that states I do not have Donkey Brains. For those who are fans of It's Always Sunny in Philadelphia you will appreciate that.

Images 2 and 3 below I'd like to point out the gym area which moves out of the way for vehicle repair. I do a little body work in that area, too. Right now I am trying to restore the body of a Retired Electrician. Not going great, needs a lot of work, probably should just part it out...

The plant you see in the image below belongs to my wife. Unfortunately it is not only surviving it is thriving. Can't eat it, can't smoke it, not sure what it does. Sacrifices we have to make for peace on earth.

I try to keep sensitive equipment protected and dust free as much as possible. The filing cabinet in the image below has been converted into an electronics work station where everything can be packed up and rolled out of the way. Notice how the second door from the bottom becomes a work table when open. Once this hack gets out I am sure the calls from SpaceX will be coming in.

Below are some other electronic test equipment. Again, put into cases for protection mainly from dust. I buy cases from Canadian Tire and Princess Auto when they go on sale. They are almost always on sale.

If I can offer any advice about planning a shop is don't forget the safety.

Fire extinguisher, eye wash station, first aid kit, carbon monoxide detector, increased air exchange when needed (I have a 2 speed exhaust fan), somebody who cares enough to come looking incase you don't come in for supper...

Last edited:

@phaxtris you probably mentioned already elsewhere, but what is the (presumably) homebuilt project?

View attachment 56491

I dont have a thread on it anywhere yet.

Its a zenith 601hd i bought out of spring bank about a year and a half ago, i just started really working on it since the prop hub was completed. It has a long way to go, there are no records of the pre-cover inspection with the appropriate people. I have obviously drilled out the center spar section for inspection, i still have yet to do the wings, that is going to be a summer thing......wings obviously take up a lot of space so i will probably do it outside, so as a result im working on the gear, fwf, all the other things i can plug away on while its cold

Ill make a thread up here in active projects soon.

Fire extinguisher, eye wash station, first aid kit, carbon monoxide detector, increased air exchange when needed (I have a 2 speed exhaust fan), somebody who cares enough to come looking incase you don't come in for supper...

Im lacking in fire extinguishers department. that's for sure I got a 1950 C02 fire extinguisher and a bucket of fire extinguisher powder lol.

Would like to install full dry powder fire suppression system in shop but probly won't be for few years unfortunately.

I feel like carbon monoxide would be annoying in a shop.

I got a large blower I plan on installing so I can Evac welding fumes from shop more efficiently

And I have tourniquet and some other trauma first aid supplies because if I'm gonna get injured doing stuff at home it's probably bad unfortunately.

I also think more people should do advanced first aid courses as the amount of people don't who dont know how to stop arterial bleeding or lesser bleeding is shockling high

Last edited:

Heh, I just finished a rebuild of a Zenith front strut & wheel. Its a cool aircraft!I dont have a thread on it anywhere yet.

Its a zenith 601hd i bought out of spring bank about a year and a half ago, i just started really working on it since the prop hub was completed. It has a long way to go, there are no records of the pre-cover inspection with the appropriate people. I have obviously drilled out the center spar section for inspection, i still have yet to do the wings, that is going to be a summer thing......wings obviously take up a lot of space so i will probably do it outside, so as a result im working on the gear, fwf, all the other things i can plug away on while its cold

Ill make a thread up here in active projects soon.

Dan Dubeau

Ultra Member

I also think more people should do advanced first aid courses as the amount of people don't who dont know how to stop arterial bleeding or lesser bleeding is shockling high

A couple blue shop towels (clean preferably), a Kant twist clamp to hold pressure, and a few wraps of electrical tape. Maybe a couple cowboys clamped on there too if its a big leaker.......😀

Last edited:

Where do i find clean blue shop towels? In my shop, even ones coming off the roll have big greasy fingerprints on them. 😀A couple blue shop towels (clean preferably),