I took the time to read Harold Halls article on drill bit sharpening (http://www.homews.co.uk/page354.html ). Good read but unless I missed it, for jobber bits, using a bench grinder, what sort of stone/wheel is recommended?

I usually have a 1" wide 80-120 grit on my right wheel. Nothing fancy but considering a second "tool bit only" bench grinder... Any preferences for wheel choice would be appreciated (for bit and tool sharpening).

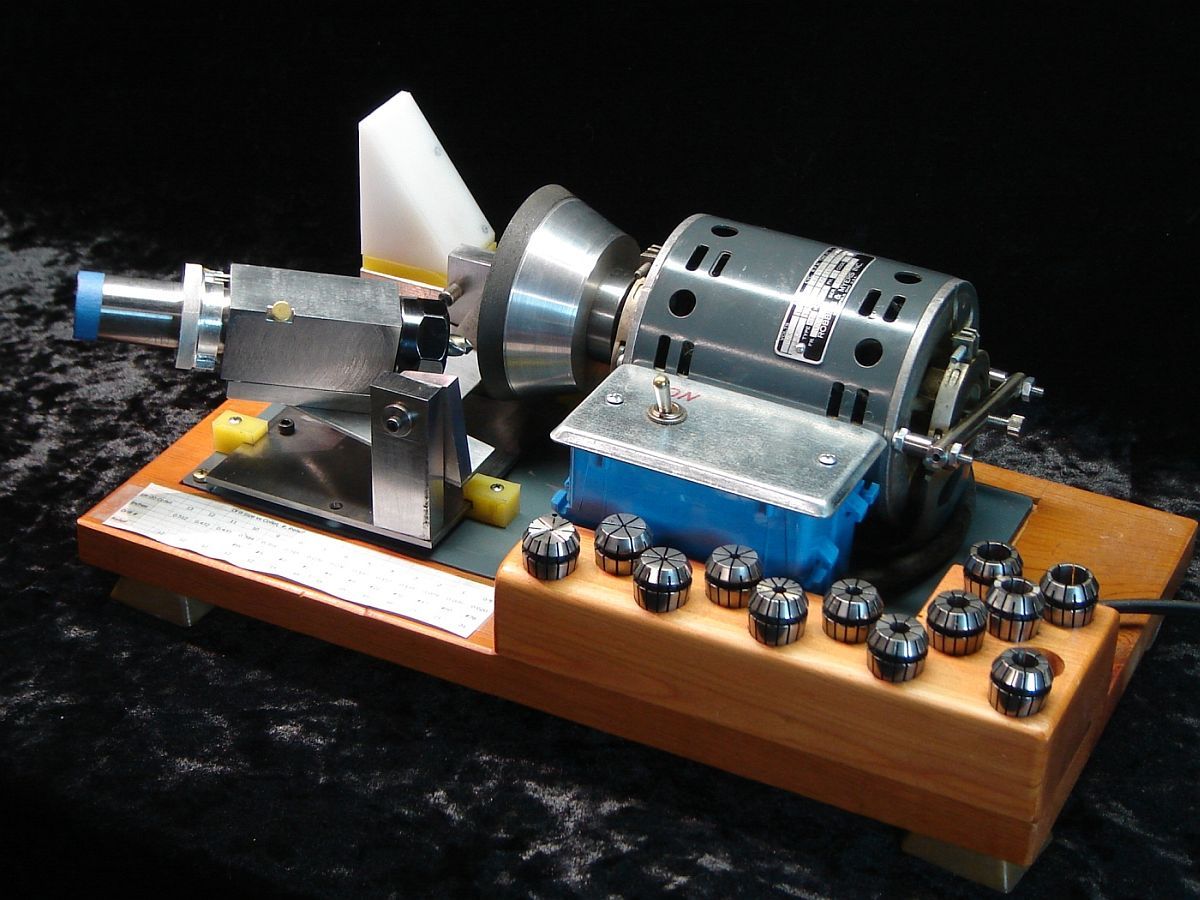

BTW, I've had Drill Doctor for years, must admit, it is incredibly frustrating and darn near useless. Watched all the videos, but can't seem to find anything that spells out how to get a great "bit" out of this contraption.... about the only thing it does well is "splitting bits".... I've just starting using a jig that Harold talks about and pretty pleased with my first efforts, looking at improving the setup.

(PS... I drink too much to sharpen anything by hand ;-) )

Cheers

Martin

I usually have a 1" wide 80-120 grit on my right wheel. Nothing fancy but considering a second "tool bit only" bench grinder... Any preferences for wheel choice would be appreciated (for bit and tool sharpening).

BTW, I've had Drill Doctor for years, must admit, it is incredibly frustrating and darn near useless. Watched all the videos, but can't seem to find anything that spells out how to get a great "bit" out of this contraption.... about the only thing it does well is "splitting bits".... I've just starting using a jig that Harold talks about and pretty pleased with my first efforts, looking at improving the setup.

(PS... I drink too much to sharpen anything by hand ;-) )

Cheers

Martin