Exactly. If one had a 127 plate made, then set the sector arms for 90 holes, there you have it.

Attached. What else can I help you with this morning? LOL

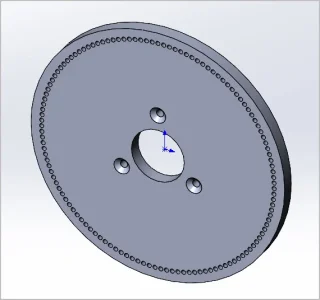

This probably illustrates another thing. I sketched this at 6" OD, 127 pin holes x 0.100" diameter just as a visual. Its getting rather tight spacing. And there could be a limitation as to how large the plate diameters can be depending on the device & installation. But this illustrates why you don't see plates available with super high hole count in order to hit minute-second angles.

I wish there was a plug-n-play electric add-on accessory for RTs. I can solder but I'm lost in the programming. If the stepper motor could be counted on to reliably increment to this kind of resolution, it would be so much easier to type in a number & watch it rotate. That's even better than a DRO display which just passively displays where you are at. Well somehow we got along with plates for the past hundred years or more. I think the reason the electronics stuff is mostly in the domain of creative hobbyists is because CNC makes quick work of this stuff. Either the mill head moves or its a 4-axis, either way digitally driven.

Attached. What else can I help you with this morning? LOL

This probably illustrates another thing. I sketched this at 6" OD, 127 pin holes x 0.100" diameter just as a visual. Its getting rather tight spacing. And there could be a limitation as to how large the plate diameters can be depending on the device & installation. But this illustrates why you don't see plates available with super high hole count in order to hit minute-second angles.

I wish there was a plug-n-play electric add-on accessory for RTs. I can solder but I'm lost in the programming. If the stepper motor could be counted on to reliably increment to this kind of resolution, it would be so much easier to type in a number & watch it rotate. That's even better than a DRO display which just passively displays where you are at. Well somehow we got along with plates for the past hundred years or more. I think the reason the electronics stuff is mostly in the domain of creative hobbyists is because CNC makes quick work of this stuff. Either the mill head moves or its a 4-axis, either way digitally driven.