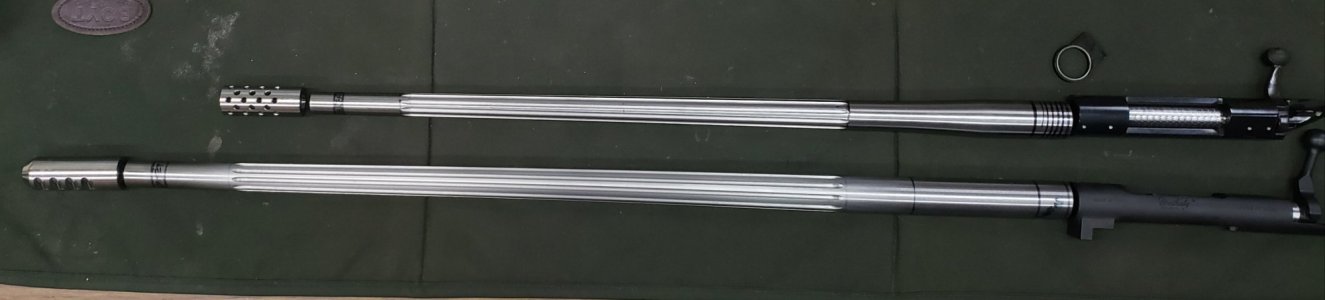

Hi Peter, when I order barrels, I specify the bore/groove dimensions, twist, contour and overall length. They are match grade single cut rifled and lapped. On my end I will thread, chamber, cut crown, engrave caliber designation, polish, and bead blast (stainless), or blue (chrome moly), flute if requested, or machine to octagon, or what ever the customer wants.I'm interested in your rotary table / chuck setup. The jaws are removed & the dog is in the T-slot? I assume you have an MT dead center passing through the chuck bore hole & into the RT socket, or??? is it an integrated chuck style? (Guess I'm just wondering what the purpose of the chuck is in this operation as opposed to completely removed ).

The picture with the cap screw, is that to provide hold down clamping to the barrel on either side of cutting action, or?

Is the barrel rough bored or finish bored or no bored at this point?

In regards to the rotary table. It has a 6" Bison three jaw chuck mounted. The table does take a MT2 centre which I am using. I don't bother removing the chuck, its accurately centered, so why bother removing it. Most of the times I can still have the jaws in place but opened up, and the centre in. I just had the jaws removed from the last job I did, and hadn't bothered to put them in. Why don't I chuck the barrel shank in the three jaw then, you might ask. Well the accuracy of a decent three jaw is at minimum 0.002" at about 2" out, but if the barrel is 30" long, I could have as much as 0.030" run out at the muzzle. No thank you.

That cap screw is there just to keep a little downward tension on the bottom support jaw.