-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rifle Barrel Fluting

- Thread starter thestelster

- Start date

Barrel is between centers. Since I'm using a side milling cutter, the side of the barrel surface has to be parallel with table movement. Less than a 0.001" over 20", that's good. Now to adjust the supports to make contact with the barrel and lock them down.

Attachments

Wow, I'm not sure I could achieve that sort of accuracy.Less than a 0.001" over 20"

This is just for the outer flutes on a barrel right? Why would it need that sort of accuracy? Is it because the lines would visually exaggerate or show the discrepancy?

It's easy enough to do. Just takes a little patience. In reality, it doesn't need to be that accurate, but your getting close to the bore, so its better to be prudent, and be as precise as possible.Wow, I'm not sure I could achieve that sort of accuracy.

This is just for the outer flutes on a barrel right? Why would it need that sort of accuracy? Is it because the lines would visually exaggerate or show the discrepancy?

Everything is set up, tightened down, speed set, rotary table at zero. Depth of cut 0.085", speed 100rpm, feed 3 ipm. Here goes.

Attachments

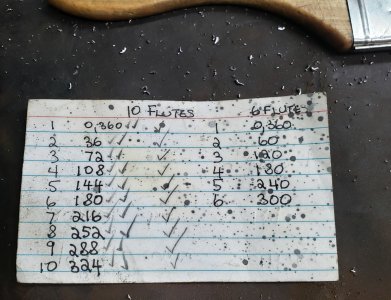

Finished flute #1. Remove top support bar, unlock rotary table advance to 36°. Lock up cutting flute #2. At 3ipm, 20" cut. Approximately 7 minutes per flute, x 10 flutes =70minutes cutting time ,and several hours set up time!!

Going on fluke #5. Up to now, I haven't had to adjust the support fingers, because they were against the smooth barrel, but now that we have rotated the barrel 180°, the horizontal jaws will be against a flute, so I have to loosen them off, make them touch. The vertical jaws are still on smooth barrel surface, so no need to adjust them yet.

Attachments

Also, after every flute cut, I unlock the tail stock and readjust. As the barrel gets hot, it lengthens, so you have to accommodate for that. And if you take a break and it cools, it shrinks, adjust accordingly. And that's here on the mill or on the lathe too. If you don't, the part can warp.

That's cool. Newbie question but do the flutes have a specific function or mostly aesthetics? You mention stainless, what is the actual alloy?

Not being a gun smith I would think the flutes reduce overall weight while maintaining accuracy and strength, likely helps to cool the barrel somewhat like a heat sink.

Dusty is correct. The most important aspect of fluting is that it creates a greater surface area, therefore it will dissipate heat quicker. Also, the barrel is stiffer compared to one of the same weight. And it looks cool.That's cool. Newbie question but do the flutes have a specific function or mostly aesthetics? You mention stainless, what is the actual alloy?

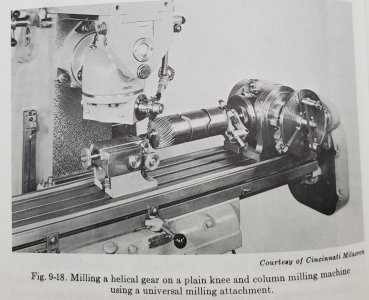

Haha, I'd love to have the helical index gearing/mechanism to do that old school!! As opposed to CNC.So next time spiral fluting?

Attachments

I believe most barrel makers use 420 or 416 stainless steel. They are slightly magnetic, and will rust as opposed to your stainless pots and pans.That's cool. Newbie question but do the flutes have a specific function or mostly aesthetics? You mention stainless, what is the actual alloy?

Former Member

Guest

The biggest danger in fluting is accidentally hitting a harmonic resonance to your preferred load. That happens accuracy goes out the window. Hit it right and your groups tighten.

Question becomes do you take this into consideration when you set up your flutes and if so any hints you wish to share?

Question becomes do you take this into consideration when you set up your flutes and if so any hints you wish to share?

I'm interested in your rotary table / chuck setup. The jaws are removed & the dog is in the T-slot? I assume you have an MT dead center passing through the chuck bore hole & into the RT socket, or??? is it an integrated chuck style? (Guess I'm just wondering what the purpose of the chuck is in this operation as opposed to completely removed ).

The picture with the cap screw, is that to provide hold down clamping to the barrel on either side of cutting action, or?

Is the barrel rough bored or finish bored or no bored at this point?

The picture with the cap screw, is that to provide hold down clamping to the barrel on either side of cutting action, or?

Is the barrel rough bored or finish bored or no bored at this point?

Attachments

Harmonic resonance happens no matter if the barrel is fluted or not, thick or thin, long or short, they all resonate, and they will all have different nodes and anti-nodes. That is one of the prime reasons to handload: to work up a particular load which is the most accurate with your barrel/action/stock combination. You are trying to work up a load so that you end up with a resonant node (minimum amplitude) at the point of bullet exit. Browning created the BOSS Ballistic Optimizing Shooting System, which was a muzzle brake that you were able to move forward or back to try to align the resonant node to the bullet exit. So if you did not handload and used factory ammunition, the best device was the BOSS, or the equivalent. But, of course you would have to readjust it if you switched ammunition, or even sometimes different lots of ammunition. So the answer to your question, is no.The biggest danger in fluting is accidentally hitting a harmonic resonance to your preferred load. That happens accuracy goes out the window. Hit it right and your groups tighten.

Question becomes do you take this into consideration when you set up your flutes and if so any hints you wish to share?