-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Replacement Gear for Craftex CT089 13x24 Lathe

- Thread starter Xyphota

- Start date

Tom Kitta

Ultra Member

It does not matter - if there is one there are more links + just ask for custom. Bottom line is they are available. I asked for custom work from ali few times, just pay a bit more.

Tom,

That seems to be the best route these days.

I was in contact with KING Canada in Montreal over the past few weeks.

All their parts are also made in China.

I am awaiting a few nylon gears in the drivetrain of my KC-15VS.

The nylon gears act as a ‘breakaway‘ component to protect the more expensive shafts and spindle, kind of like a shear pin in a machinery driveline.

That seems to be the best route these days.

I was in contact with KING Canada in Montreal over the past few weeks.

All their parts are also made in China.

I am awaiting a few nylon gears in the drivetrain of my KC-15VS.

The nylon gears act as a ‘breakaway‘ component to protect the more expensive shafts and spindle, kind of like a shear pin in a machinery driveline.

Xyphota

Ultra Member

I've got the gear installed and have reinstalled the spindle and am now at the point to adjust the headstock bearing preload. The CT089 manual does not have any instructions on how to gauge if you have enough preload or not. Some other discussions I found on the interwebs say that the lathe should be run at a medium speed for an hour, and then put it into neutral and give the chuck a sharp yank by hand, and the correct amount of drag will permit 1 free rotation. Does anyone else have a chinese lathe with a manual that has recommendations?

terry_g

Ultra Member

I am interested to hear the members opinions on how to set the pre-load on the spindle bearings.

The method you described where you give the chuck a yank would vary depending on the weight

of the chuck and the number of gears that are rotating with the spindle when you yank on it and

the strength of the person yanking on the chuck. It sounds a bit unreliable to me. My guess would

be that you want .003" to .005" pre-load on the bearings.

What is the thread pitch on the adjustment nut on the spindle? How is the adjustment nut locked

after the pre-load is set? A jam nut can add pre-load when tightened.

You can calculate the pre-load from the thread pitch on the spindle thread.

Adjust the spindle bearings to zero pre-load and zero end play. The bearing rollers spread out after the

bearings make a few rotations and change the end play. Then tighten the adjustment to get the

needed pre-load.

The method you described where you give the chuck a yank would vary depending on the weight

of the chuck and the number of gears that are rotating with the spindle when you yank on it and

the strength of the person yanking on the chuck. It sounds a bit unreliable to me. My guess would

be that you want .003" to .005" pre-load on the bearings.

What is the thread pitch on the adjustment nut on the spindle? How is the adjustment nut locked

after the pre-load is set? A jam nut can add pre-load when tightened.

You can calculate the pre-load from the thread pitch on the spindle thread.

Adjust the spindle bearings to zero pre-load and zero end play. The bearing rollers spread out after the

bearings make a few rotations and change the end play. Then tighten the adjustment to get the

needed pre-load.

Proxule

Ultra Member

LOL, When are we going for beers? !Oh for Gods sake just buy from China -

Former Member

Guest

Another source is Grizzly and PM, find the same lathe download the manual and see if they have the parts. Requires a bit of digging but can yield great results.

Check out this store on Aliexpress. He carries lots of parts for the Asian equipment.

The OP (@Xyphota) isn't looking for parts anymore. He wants to know the procedure for adjusting the spindle bearing preload.

I can't help with that. I had hoped more experienced members would chime in. But when they don't, I sometimes find that offerring some advice myself brings them out of the woodwork. LMFAO!

I believe it is machine specific. I've seen some with tapered roller bearings where you adjust to achieve a specific temperature increase in operation. Given the variables involved, I think that really boils down to warm to touch is good, hot is bad. Good luck finding an exact temp increase let alone a detailed procedure to obtain it.

Another approach would be to see if you can find your bearing or its equivalent on a bearing manufacturers website. The better bearing makers publish specifications and sometimes even methods. In my mind this might even be better than following busy bees advice - assuming you ever get any. At the very least, you might be able to identify a better middle ground.

But the bottom line is that I don't really know how the CT089 is done.

However, your need makes me realize that I don't know exactly how mine is done either. These hot humid days are a perfect excuse for taking the time to dig that up. I'll let you know if I find anything on the CT089 in the process.

I'd go with warm to touch after 30 minutes at high speed if you don't find better info.

I can hear keyboards clicking from here!

I can't help with that. I had hoped more experienced members would chime in. But when they don't, I sometimes find that offerring some advice myself brings them out of the woodwork. LMFAO!

I believe it is machine specific. I've seen some with tapered roller bearings where you adjust to achieve a specific temperature increase in operation. Given the variables involved, I think that really boils down to warm to touch is good, hot is bad. Good luck finding an exact temp increase let alone a detailed procedure to obtain it.

Another approach would be to see if you can find your bearing or its equivalent on a bearing manufacturers website. The better bearing makers publish specifications and sometimes even methods. In my mind this might even be better than following busy bees advice - assuming you ever get any. At the very least, you might be able to identify a better middle ground.

But the bottom line is that I don't really know how the CT089 is done.

However, your need makes me realize that I don't know exactly how mine is done either. These hot humid days are a perfect excuse for taking the time to dig that up. I'll let you know if I find anything on the CT089 in the process.

I'd go with warm to touch after 30 minutes at high speed if you don't find better info.

I can hear keyboards clicking from here!

@Xyphota - amazing what a fellow can find. The method on my lathe is to warm up the lathe on high speed for 30 minutes, find the zero play point by experimenting with loosening the spindle preload, pushing the spindle out manually or with a block of wood and a hammer, mounting an indicator, tightening slowly till the indicator stops moving, then tighten the preload nut an additional 1/16" on its diameter. Confirm by running another 30 minutes - should be warm to touch but not hot. A hot bearing is too tight, a cool bearing is too loose.

Edit - If I were doing it, I'd have a chuck mounted during warm up. I'd use a 10ths dial test indicator on the face of my chuck. And I'd rotate the chuck back and forth a bit to settle the bearing rollers while looking for zero.

Thanks for the incentive to find my own. Might work for you too.

Edit 2 - Just noodling this a wee bit as an engineer. The goal is a spindle that runs true and also doesn't cause chatter in the work. Precision roller bearings require a scootch of preload to accomplish that. Temp and load both cause metal to move. Consistency dictates that both be stabilized. My guts tell me that the warm to the touch after 30 minutes method accomplishes the goal no matter what the design. I'd also guess that the temp is very sensitive to preload so temp serves as a great torque wrench. For my lathe, zero plus a 1/16th just gets you close faster, but litmus test is temp. In other words the goal is actually temp and the method is secondary. If that makes sense to anybody but me.....

Edit - If I were doing it, I'd have a chuck mounted during warm up. I'd use a 10ths dial test indicator on the face of my chuck. And I'd rotate the chuck back and forth a bit to settle the bearing rollers while looking for zero.

Thanks for the incentive to find my own. Might work for you too.

Edit 2 - Just noodling this a wee bit as an engineer. The goal is a spindle that runs true and also doesn't cause chatter in the work. Precision roller bearings require a scootch of preload to accomplish that. Temp and load both cause metal to move. Consistency dictates that both be stabilized. My guts tell me that the warm to the touch after 30 minutes method accomplishes the goal no matter what the design. I'd also guess that the temp is very sensitive to preload so temp serves as a great torque wrench. For my lathe, zero plus a 1/16th just gets you close faster, but litmus test is temp. In other words the goal is actually temp and the method is secondary. If that makes sense to anybody but me.....

Last edited:

historicalarms

Ultra Member

I will relay the method I used to set pre-load on dozens of transport wheels when changing bearings or doing a removal for a leaky seal. If I were doing the lathe spindle in question i would do it the same way.... "I never had a wheel fall off" LOLI believe it is machine specific. I've seen some with tapered roller bearings where you adjust to achieve a specific temperature increase in operation. Given the variables involved, I think that really boils down to warm to touch is good, hot is bad. Good luck finding an exact temp increase let alone a detailed procedure to obtain it.

first off I dont agree with the "specific temp increase", if I ever had a wheel that showed even a small noticable temp increase after a short trip ( 5 mi or so) after repair, it would have been re-done-re set immediately.

My method: With eve3rything still jacked up so no groung interference to the wheel at all, I would tighten the inside nut to be tight enough that i couldnt move the wheel at all. This makes sure everything is luined up and where it is supposed to be, now I loosen that nut a complete turn and give that wheel a s mighty a spin as I could....now, as it spins I re-tighten the nut untill the wheel is just stopped from spinning by bearing tightness pressure, now back off that inside nut a 1/4 turn and set the outside locking collars or nuts however your outfit is set up and your done.

I would do the same thing with the lathe, give the chuck a mighty spin and tighten the bearings up while spinning.

now back off that inside nut a 1/4 turn and set the outside locking collars or nuts however your outfit is set up and your done.

I agree with you totally - for wheel bearings. But the goal for a wheel bearing is long life under very high loads. The goal on a lathe is concentricity without chatter - bearing life and load bearing capacity are significantly less important. I think backing off the preload will allow too much chatter as well as a loss of concentricity.

That said, I am absolutely certain your method would work just as it does for wheel bearings. As the old saying goes, if it works for you (on your lathes), be happy!

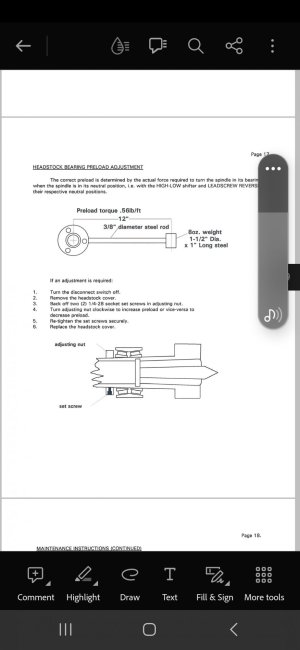

This is the adjustment procedure for Standard Modern 1340 lathe.

Hey @Susquatch maybe we should have a separate post on adjusting pre-loads. From all the different manufacturers as well as bearing suppliers.

Hey @Susquatch maybe we should have a separate post on adjusting pre-loads. From all the different manufacturers as well as bearing suppliers.

Attachments

This is the adjustment procedure for Standard Modern 1340 lathe.

I'm surprised it doesn't say anything about whether that is cold or after running for a while. The two situations would be different.

Xyphota

Ultra Member

So funnily enough I completed the first step of this procedure - run for 30 minutes and then adjust preload to eliminate and play - and now my contactor is cooked LOL.amazing what a fellow can find. The method on my lathe is to warm up the lathe on high speed for 30 minutes, find the zero play point by experimenting with loosening the spindle preload, pushing the spindle out manually or with a block of wood and a hammer, mounting an indicator, tightening slowly till the indicator stops moving, then tighten the preload nut an additional 1/16" on its diameter. Confirm by running another 30 minutes - should be warm to touch but not hot. A hot bearing is too tight, a cool bearing is too loose.

So funnily enough I completed the first step of this procedure - run for 30 minutes and then adjust preload to eliminate and play - and now my contactor is cooked LOL.

Well, look at the bright side. You know what blew and you know how fix it. Many of us folks would be totally pissed off, ready to kill something, and taking a cold shower right now.

Any idea why it blew? Too much current at highest rpm? If so, it was marginal anyway.

Xyphota

Ultra Member

It just got really hot. It's a cheap contactor and its probably 20 years old so it probably didn't like the 30 minutes of continuous use. This is actually my work's lathe so I got the ok to buy a name brand contactor locally so I was able to replace it this afternoon. I ran it for an additional 30 minutes on the old contactor after adjusting the bearing preload and the housing around the bearings felt slightly warmer than metal elsewhere on the lathe so I think its set correctly. I will be turning some aluminum tomorrow so we will see!

Did you deburr the gear? That can make a difference.I may have discovered why the lathe had a plastic gear. This thing is LOUD as hell with the new steel gear if I run it over 1000 rpm LOL