Xyphota

Ultra Member

Hello All,

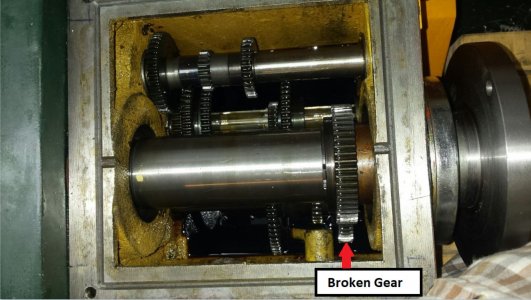

I have sheared some teeth off this plastic gear in the drivetrain of my craftex CT089 lathe. All the gears in the lathe are metal, except for this gear which is the one responsible for driving the spindle. Fortunately it performed its job adequately and gave up the dust before damaging the spindle I suppose lol. Additionally, it looks like the gear stalled and the keyed shaft its mated to just started line boring out the bore lol.

I have emailed busy bee and am eagerly awaiting a response for a replacement, but I have also been looking elsewhere for a replacement as I would like to get this lathe repaired quickly. I have not dealt with busy bee customer support before so I do not know what to expect for timing.

The gear looks to be a 1.5 module, 56 tooth gear. 15mm face width, 10 mm hub projection for a total width of 25mm. 20mm bore diameter with a 5mm keyway slot. Visually the pressure angle appears to be 20 degrees, but I am honestly not sure. KHKgears, SDP/SI have configuartions of this gear, but nothing readily availble. For fun I contacted rushgear and they could make me one in two weeks for $2800 USD lol. I have access to a second lathe I can use to increase the bore size or reduce the shoulder projection if I can find something close atleast.

Does anyone have any recommendations as to where else to look for a replacement? And, if I am unable to find a plastic replacement gear, would I be stupid to install a steel gear?

I have sheared some teeth off this plastic gear in the drivetrain of my craftex CT089 lathe. All the gears in the lathe are metal, except for this gear which is the one responsible for driving the spindle. Fortunately it performed its job adequately and gave up the dust before damaging the spindle I suppose lol. Additionally, it looks like the gear stalled and the keyed shaft its mated to just started line boring out the bore lol.

I have emailed busy bee and am eagerly awaiting a response for a replacement, but I have also been looking elsewhere for a replacement as I would like to get this lathe repaired quickly. I have not dealt with busy bee customer support before so I do not know what to expect for timing.

The gear looks to be a 1.5 module, 56 tooth gear. 15mm face width, 10 mm hub projection for a total width of 25mm. 20mm bore diameter with a 5mm keyway slot. Visually the pressure angle appears to be 20 degrees, but I am honestly not sure. KHKgears, SDP/SI have configuartions of this gear, but nothing readily availble. For fun I contacted rushgear and they could make me one in two weeks for $2800 USD lol. I have access to a second lathe I can use to increase the bore size or reduce the shoulder projection if I can find something close atleast.

Does anyone have any recommendations as to where else to look for a replacement? And, if I am unable to find a plastic replacement gear, would I be stupid to install a steel gear?