Hi Jon. The plans were purchased here, Martin Ohrdorf. http://www.engineman.de/

Bit of background story. I originally bought the 9-cyl plans a few years back, but it was for design reference when I was naively contemplating my own 5-cyl radial design. Then one day I noticed he subsequently offered a 5-cyl version that shares certain 9-cyl components. So I ended up getting the 5-cyl plans figuring the smaller brother would be a big enough challenge for me. Unfortunately he makes you buy both sets (or at least he did at the time) which is a bit goofy since they are 2D drawings of 3D Cad assembly which could be offered as standalone IMO. But since I already had the 9 plans, I took the leap. He also offers a V12 & a double row 7 (14 cyl corncob) which look to be similar design methodology. There are some Youtubes of his engines running. Correspondence is spotty at best (maybe language issue).

I’ll mention some other options because this absorbed a lot of my decision making time.

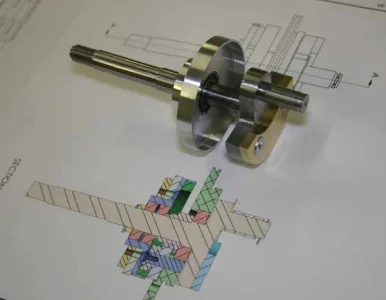

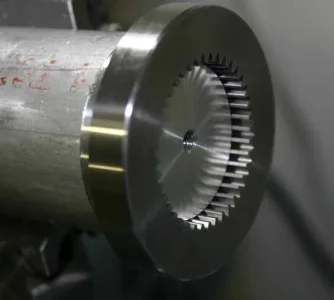

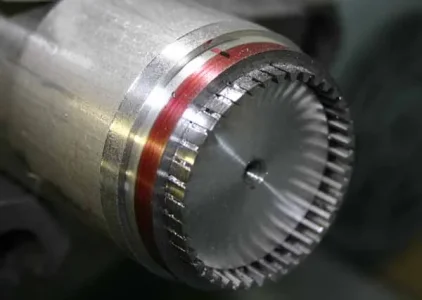

Free (legitimate free) PDF plans are available for the Edwards engine 5-cyl radial which is quite similar. I have a copy if you are interested (version A08a), otherwise I think you just need to join Yahoo R&R user group to access. There are some pros & cons & slight aesthetic differences. Edwards has integrated mechanical lubrication pump so it runs pure methanol as fuel & circulates oil where required. This would be my preference over the typical premix oil/methanol RC fuel, but they seem to run ok & the commercial engines are premix too. The Edwards has some documented builds on some forums, not the case with Ohrdorf. I was prepared to start the Edwards but found difficulty sourcing the internal (IMP) tooth ring gear. That’s the one critical thing you need to nail down beforehand on these radials. External spur gears can be made by hobby machinists but internal ring tooth form, especially at this scale & ideally hardened, not so easy. Unfortunately it’s the heart of the engine design because of physical size & requisite gear ratio combination for cam lobe timing etc. The euro engines use same crankshaft > idler > ring gear > lobe cam principal but use module (metric) gears. I was able to locate the metric one so that sealed the deal. Since then I’ve stumbled on the required Edwards ring gear, but too late now.

Here is another supplier which look to be pretty good designs. They also offer some simpler & lower cylinder count engines - probably what I should have pursued first, but oh well. They are also methanol fuel / glow ignition, all metric. And also a 5-cyl radial btw.

http://www.cad-jung-shop.de/epages/62479729.sf/de_DE/?ObjectPath=/Shops/62479729/Categories/Baupl%C3%A4ne/Bauplane_Modellmotore

This link shows some build pics of the 7-cyl radial.

http://philsradial.blogspot.ca/

Bit of background story. I originally bought the 9-cyl plans a few years back, but it was for design reference when I was naively contemplating my own 5-cyl radial design. Then one day I noticed he subsequently offered a 5-cyl version that shares certain 9-cyl components. So I ended up getting the 5-cyl plans figuring the smaller brother would be a big enough challenge for me. Unfortunately he makes you buy both sets (or at least he did at the time) which is a bit goofy since they are 2D drawings of 3D Cad assembly which could be offered as standalone IMO. But since I already had the 9 plans, I took the leap. He also offers a V12 & a double row 7 (14 cyl corncob) which look to be similar design methodology. There are some Youtubes of his engines running. Correspondence is spotty at best (maybe language issue).

I’ll mention some other options because this absorbed a lot of my decision making time.

Free (legitimate free) PDF plans are available for the Edwards engine 5-cyl radial which is quite similar. I have a copy if you are interested (version A08a), otherwise I think you just need to join Yahoo R&R user group to access. There are some pros & cons & slight aesthetic differences. Edwards has integrated mechanical lubrication pump so it runs pure methanol as fuel & circulates oil where required. This would be my preference over the typical premix oil/methanol RC fuel, but they seem to run ok & the commercial engines are premix too. The Edwards has some documented builds on some forums, not the case with Ohrdorf. I was prepared to start the Edwards but found difficulty sourcing the internal (IMP) tooth ring gear. That’s the one critical thing you need to nail down beforehand on these radials. External spur gears can be made by hobby machinists but internal ring tooth form, especially at this scale & ideally hardened, not so easy. Unfortunately it’s the heart of the engine design because of physical size & requisite gear ratio combination for cam lobe timing etc. The euro engines use same crankshaft > idler > ring gear > lobe cam principal but use module (metric) gears. I was able to locate the metric one so that sealed the deal. Since then I’ve stumbled on the required Edwards ring gear, but too late now.

Here is another supplier which look to be pretty good designs. They also offer some simpler & lower cylinder count engines - probably what I should have pursued first, but oh well. They are also methanol fuel / glow ignition, all metric. And also a 5-cyl radial btw.

http://www.cad-jung-shop.de/epages/62479729.sf/de_DE/?ObjectPath=/Shops/62479729/Categories/Baupl%C3%A4ne/Bauplane_Modellmotore

This link shows some build pics of the 7-cyl radial.

http://philsradial.blogspot.ca/