mprozycki

Member

Hello fellow enthusiasts,

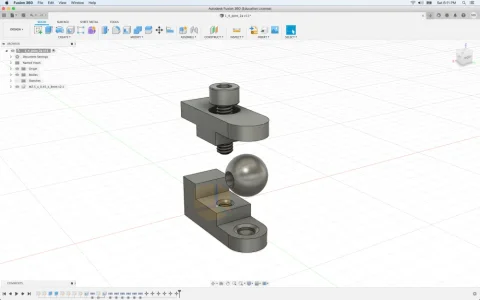

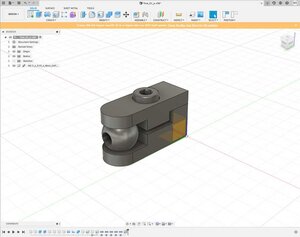

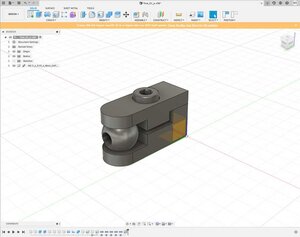

I've been trying to reverse engineer some ball-socket joint designs using 360 fusion. I purchased these joints from John Wright model maker in the U.K. I'm doing this for personal use as I am a fan of stop-motion animation.

The current joint I'm studying is made of stainless steel plates with a coated stainless steel ball. I also have a previous version that was made from mild steel and a 304 stainless steel ball (no coating). You can see both in the attached pic.

I just would like to find out more information on the coating used with the new joint design?

I'm assuming it's TiC to help improve mechanical function. I've read that these coatings help with lubrication and wear, among other things.

If someone knows a bit more about this sort of process, please fell free to share. Thank you.

I've been trying to reverse engineer some ball-socket joint designs using 360 fusion. I purchased these joints from John Wright model maker in the U.K. I'm doing this for personal use as I am a fan of stop-motion animation.

The current joint I'm studying is made of stainless steel plates with a coated stainless steel ball. I also have a previous version that was made from mild steel and a 304 stainless steel ball (no coating). You can see both in the attached pic.

I just would like to find out more information on the coating used with the new joint design?

I'm assuming it's TiC to help improve mechanical function. I've read that these coatings help with lubrication and wear, among other things.

If someone knows a bit more about this sort of process, please fell free to share. Thank you.

Last edited: