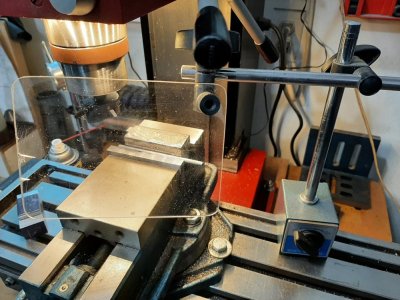

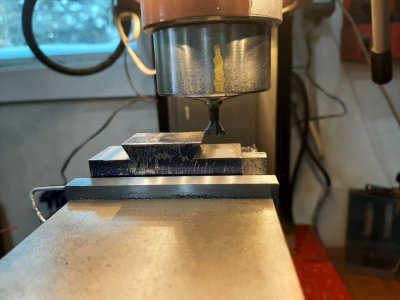

1" square stock to start..... Tool holders to finish. This project lead to questions in another thread about depth of cut with milling cutters of different types in small mills. This project was started a few days ago, but deferred because of questions, problems, and other projects like the bench lamp part.

Back to this project..... After reading other threads, I have decided that it is probably better to remove as much stock as possible via means other than the small mill I have access to so will bandsaw out the bulk that I can, and then get to the actual more precise cuts. Every day, learning something new.

Pic got twisted I think. Middle one is the rusty old but painted stock to start. Will grind that crud off. First attempt on the right (ongoing) and factory original at left. Just a China cheapy tool that I have had for years and not used because it needed some adaption for my lathe but after revisiting it, I have decided it will be good, if I had more holders. So, here we go.

I have some dovetail cutters but not used them. I probably bought them for this project years ago. I think questions might follow when I get to that point. I am assuming to get everything cut close with straight cutters, then start milling with the dovetail cutters....?

Back to this project..... After reading other threads, I have decided that it is probably better to remove as much stock as possible via means other than the small mill I have access to so will bandsaw out the bulk that I can, and then get to the actual more precise cuts. Every day, learning something new.

Pic got twisted I think. Middle one is the rusty old but painted stock to start. Will grind that crud off. First attempt on the right (ongoing) and factory original at left. Just a China cheapy tool that I have had for years and not used because it needed some adaption for my lathe but after revisiting it, I have decided it will be good, if I had more holders. So, here we go.

I have some dovetail cutters but not used them. I probably bought them for this project years ago. I think questions might follow when I get to that point. I am assuming to get everything cut close with straight cutters, then start milling with the dovetail cutters....?

Attachments

Last edited: