I've been sorting through a kind of a background harmonic resonance issue on my (single phase 220V mill). A few forum buddies have been in the loop. I made some good 'mechanical progress', its certainly much better than it was.

One of the things that came up in discussion is apparently some residential lines can be noisier than others. I 'think' the power companies are supposed to be within some kind of tolerance band, I may have read +/- 5% somewhere. I'm using the word power loosely because I'm not sure if that means voltage specifically or the waveform or levels of AC current.

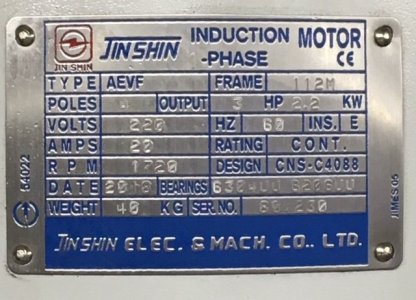

Hypothetically, with a 3HP belt driven motor just idling unloaded, would it be normal for its RPM to vary (the same example 5%) purely based on what's coming in the wall? Is this something that can be quantified with simple test instruments to really needs some kind of scope? Other than my 2HP SP lathe (which is bucking a gear box at idle) I don't have anything else to compare against. How about the motor itself, does it have anything internal that might react or dampen input power in this regard? Now there very well may be some mechanical reasons behind this, but many of the obvious things have been evaluated in detail. I'm just curious about this aspect because it arose in discussion.

I didn't think this was a thing in a typical city setting, but I also recall some people had to get old lines 'fixed' to solve flickering issues. And I seem to remember some of our field offices in more remote settings had to have (I think they are called power conditioners) installed because of even common office machines, computers, faxes, appliance type devices going glitchy on them - end of the line effects or however they worded it.

One of the things that came up in discussion is apparently some residential lines can be noisier than others. I 'think' the power companies are supposed to be within some kind of tolerance band, I may have read +/- 5% somewhere. I'm using the word power loosely because I'm not sure if that means voltage specifically or the waveform or levels of AC current.

Hypothetically, with a 3HP belt driven motor just idling unloaded, would it be normal for its RPM to vary (the same example 5%) purely based on what's coming in the wall? Is this something that can be quantified with simple test instruments to really needs some kind of scope? Other than my 2HP SP lathe (which is bucking a gear box at idle) I don't have anything else to compare against. How about the motor itself, does it have anything internal that might react or dampen input power in this regard? Now there very well may be some mechanical reasons behind this, but many of the obvious things have been evaluated in detail. I'm just curious about this aspect because it arose in discussion.

I didn't think this was a thing in a typical city setting, but I also recall some people had to get old lines 'fixed' to solve flickering issues. And I seem to remember some of our field offices in more remote settings had to have (I think they are called power conditioners) installed because of even common office machines, computers, faxes, appliance type devices going glitchy on them - end of the line effects or however they worded it.