-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cyclical Mill Vibration & Power Discussion

- Thread starter PeterT

- Start date

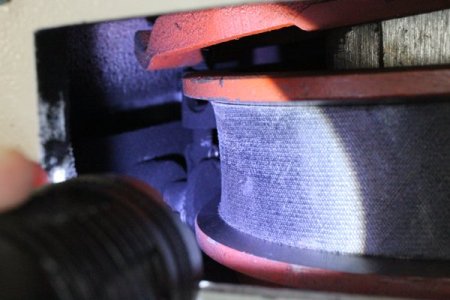

The 935 has 2 belts. The larger variable speed belt & smaller motor drive belt. Both were checked visually & confirmed as new condition - no cracks, no edge wear, laid perfectly flat on table, minimal dust in the head. Not sure if a linked belt would apply in this case, I could inquire.

The drive belt was replaced because a) it was in stock at time of rebuild b) I was concerned it was riding a bit low on the stepped pulley possibly indicating it was stretched or slightly large from factory & might be contributing to a belt resonance 'flap'. I've since learned this vertical belt position is 'normal' or at least not deemed problematic. With the head off its more obvious there is running gap between the belt 7 casting so no clearance issue.

Now the variable speed drive belt, only in hindsight, I wish I replaced. But that's only rearview mirror assessment because there is still a hint of background resonant noise once all assembled again. But the machine is significantly quieter than when the slightly loose-ish bearing was replaced in gear shaft assembly = the prime suspect at the time. Had the noise been 100% removed instead of 90% removed, then the vari-speed belt would not have been required. I've been told that even though belts can look good & measure good, they can still have 'something' amiss that can cause a harmonic, be it composition or Monday morning rubber batch? I dunno. So that may well be the next step if this noise slowly reverts to worsening over time. That's the rather frustrating chicken & egg thing, maybe the shaft bearing was the effect of the belt vs the other way around. I do recognize the noise is on my OCD radar so one opportunity mentioned to me is another member has the same machine, I'll be listening to it soon just to compare. That wont help my machine specifically but at least will give me baseline expectation of what 'normal' sounds like again.

The drive belt was replaced because a) it was in stock at time of rebuild b) I was concerned it was riding a bit low on the stepped pulley possibly indicating it was stretched or slightly large from factory & might be contributing to a belt resonance 'flap'. I've since learned this vertical belt position is 'normal' or at least not deemed problematic. With the head off its more obvious there is running gap between the belt 7 casting so no clearance issue.

Now the variable speed drive belt, only in hindsight, I wish I replaced. But that's only rearview mirror assessment because there is still a hint of background resonant noise once all assembled again. But the machine is significantly quieter than when the slightly loose-ish bearing was replaced in gear shaft assembly = the prime suspect at the time. Had the noise been 100% removed instead of 90% removed, then the vari-speed belt would not have been required. I've been told that even though belts can look good & measure good, they can still have 'something' amiss that can cause a harmonic, be it composition or Monday morning rubber batch? I dunno. So that may well be the next step if this noise slowly reverts to worsening over time. That's the rather frustrating chicken & egg thing, maybe the shaft bearing was the effect of the belt vs the other way around. I do recognize the noise is on my OCD radar so one opportunity mentioned to me is another member has the same machine, I'll be listening to it soon just to compare. That wont help my machine specifically but at least will give me baseline expectation of what 'normal' sounds like again.

Attachments

Is this from listening to the audio or do you have some kind of analysis software/app that provides insight?you must have some kind of balance or alignment problem

What is odd (and should be meaningful) is kind of the low frequency overlay noise that comes in & out. Like something goes out of balance/alignment & then comes in balance again. Like brrrrt...quiet...brrrrt...quiet. Guessing like 2 sec intervals? Anything loose or worn would be more of a constant noise. Maybe the speed change belt could do this if it was somehow defective but as mentioned visibly looked perfect. If it gets worse again over time, I guess its the next thing.

Based on the videos that you shared, you must have some kind of balance or alignment problem. In addition to the sound, there seems to be a visible vibration. If that's right (it is hard to be sure from the video), it is hard to give any more specific advise

What audio? I didn't see any audio! The video wasnt @PeterT 's.

He sent me a link to a OneDrive location via PM

Well that sucks! I was all excited to listen. Now I feel left out.

Think I'll just go to bed. I spent most of today clearing snow so I'm beat anyway.

I flicked it on again tonight just while I was in the shop. It actually sounds worse now :/ Then improved but at different rpms. Maybe the belt(s) need to seat in after the rebuild. Think I'll go to bed too, I'm about ready to hang myself. Planning a visit this week to an older year but same model. It wont tell me anything about my issue other than possibly what 'base level' operating sounds should be & go from there. Frustrating.

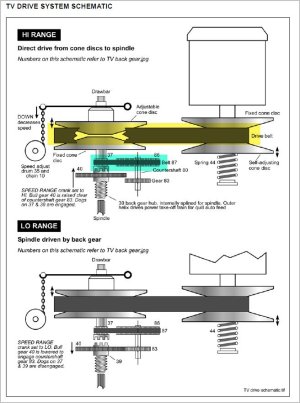

Some good thoughts. Executing them is not exactly easy although after the service visit I have a much better understanding of what's involved by helping the millwright/service tech. Lifting & unhooking the motor off the belt/sheave is a bit of an aerial maneuver & a 2-man job to do it safely without rigging gear. The motor is typical machined flange plate, no gasket or anything like that in between. Could it be slightly off alignment or shaft runout? yes. It ran smooth on the ground almost a silent hum. Not a definitive test but enough to keep looking elsewhere. I'm not sure the belts can be run in flip-flop isolation quite that way. This sketch shows the 2 belts (but not to scale). In order for anything to turn, the motor must be engaged via the vari-speed (Reeves type system) belt. I suppose it could be run without the lower countershaft HI/LOW belt. That belt was replaced but Varispeed belt was not. Any listening on the lower side of head in spindle area is silky smooth, I just don't think any issue there. And this 'noise' does not reflect on cutting finish quality, its just plain irritating to th eears. More & more I'm suspecting the Varispeed belt/related but getting ahead of myself

I am scheduled to see an older cousin 935 running pretty soon. Whether its quieter or noisier or different is almost a moot point because it doesn't solve my issue, just provides me a convenient, audible point of reference. But still worth the effort because (my understanding) same machine, just older.

Now yesterday I had the side vent covers off & spent probably 40 min running with flashlight pointed in every nook & cranny, thin sticks on the wheels & belts trying to correlate vibrations, screwdriver listening hear & there & everywhere, changing speeds, FWD/REV HI/LOW, changing the pace of speed crank wheel, approaching resonant RPM from either low or high rpm side.... I have a new set of videos just need to get them on PC. Now the bruised forehead update: It sounds better! Or at least different. I'm not sure if the belts are warming up with continuous running or reseating itself after some running in. But the harmonic RPM range seems to be moving around a bit from where it was & also in intensity.

- basically no harmonic in low gear FWD or REV. Behind the scenes, Low detaches the dog & engages bull gear, but in all scenarios both belts are running, so WTF

- in high gear REV direction, now basically no harmonic. I definitely had noise before, so WTF

- in high gear FWD direction, its getting better, or at least seemed to be getting better with running. But the harmonic range is shifting a bit. 900-1000 RPM is still where it comes on but it varies a bit. The weird thing is, below 700 it completely disappears. Above 1200 it gets better & better. So makes no obvious sense to me what could be worn or loose to yield this combination. The bugger wants to be noisy where I spend 70% of my time. I just need to find a pail of opposite endmills & drills haha :/

- I stared at the belts & sheaves & cranked the speeds up & down. Nothing is standing out. A coffee stir stick lightly rubbing on a moving surface is a very crude instrument but it actually can feel quite minor variations. I noticed my LED flashlight must actually operate on pulsations because at certain RPMs I can kind of see freeze frame effect. Unfortunately not at the harmonic rpms. It would be nice to have access to one of those vibration strobe guns if thast what they are called,

My gut feel today (which may change tomorrow) is something is up with the vari-speed belt. Maybe some teeth are ever so slightly 'out' dimensionally so it looks ok from a foot away but is enough to set up some reverberations. Then the echo is getting transmitted to mechanical parts & everybody is under suspicion by association? I did notice the belt was upside down via lettering, but I didn't see any direction arrows & of course motor goes either direction. I'm just now looking to see if it was the other way round originally. Should it make a difference?

Questions

- why would there be essentially no harmonic running in reverse vs forward when everything else is identical?

- is there any kind of belt conditioning spray that 'quiets' the rubber or is that asking for trouble? I got the impression from tech that a 3 year old machine run hard with in ugly belt can have 6mm of rubber dust everywhere in the head. Mine has less than 1mm & only in select areas & none in other areas. But anyways, maybe a spray, even like a 'dry spray' is not conducive to a rubber dust making mechanism? Maybe it turns it into black goo & doesnt help the actual friction surface belt to steel?

I am scheduled to see an older cousin 935 running pretty soon. Whether its quieter or noisier or different is almost a moot point because it doesn't solve my issue, just provides me a convenient, audible point of reference. But still worth the effort because (my understanding) same machine, just older.

Now yesterday I had the side vent covers off & spent probably 40 min running with flashlight pointed in every nook & cranny, thin sticks on the wheels & belts trying to correlate vibrations, screwdriver listening hear & there & everywhere, changing speeds, FWD/REV HI/LOW, changing the pace of speed crank wheel, approaching resonant RPM from either low or high rpm side.... I have a new set of videos just need to get them on PC. Now the bruised forehead update: It sounds better! Or at least different. I'm not sure if the belts are warming up with continuous running or reseating itself after some running in. But the harmonic RPM range seems to be moving around a bit from where it was & also in intensity.

- basically no harmonic in low gear FWD or REV. Behind the scenes, Low detaches the dog & engages bull gear, but in all scenarios both belts are running, so WTF

- in high gear REV direction, now basically no harmonic. I definitely had noise before, so WTF

- in high gear FWD direction, its getting better, or at least seemed to be getting better with running. But the harmonic range is shifting a bit. 900-1000 RPM is still where it comes on but it varies a bit. The weird thing is, below 700 it completely disappears. Above 1200 it gets better & better. So makes no obvious sense to me what could be worn or loose to yield this combination. The bugger wants to be noisy where I spend 70% of my time. I just need to find a pail of opposite endmills & drills haha :/

- I stared at the belts & sheaves & cranked the speeds up & down. Nothing is standing out. A coffee stir stick lightly rubbing on a moving surface is a very crude instrument but it actually can feel quite minor variations. I noticed my LED flashlight must actually operate on pulsations because at certain RPMs I can kind of see freeze frame effect. Unfortunately not at the harmonic rpms. It would be nice to have access to one of those vibration strobe guns if thast what they are called,

My gut feel today (which may change tomorrow) is something is up with the vari-speed belt. Maybe some teeth are ever so slightly 'out' dimensionally so it looks ok from a foot away but is enough to set up some reverberations. Then the echo is getting transmitted to mechanical parts & everybody is under suspicion by association? I did notice the belt was upside down via lettering, but I didn't see any direction arrows & of course motor goes either direction. I'm just now looking to see if it was the other way round originally. Should it make a difference?

Questions

- why would there be essentially no harmonic running in reverse vs forward when everything else is identical?

- is there any kind of belt conditioning spray that 'quiets' the rubber or is that asking for trouble? I got the impression from tech that a 3 year old machine run hard with in ugly belt can have 6mm of rubber dust everywhere in the head. Mine has less than 1mm & only in select areas & none in other areas. But anyways, maybe a spray, even like a 'dry spray' is not conducive to a rubber dust making mechanism? Maybe it turns it into black goo & doesnt help the actual friction surface belt to steel?

Attachments

When you are in the speed zone that the resonance occurs, do you have a way of measuring the spindle RPM? Is it fluctuating? Probably too hard to measure accurately enough..

The other silly thought I had - do you have a tool in the spindle or is the drawbar just loose?

As for spray - I can't recommend any. I've only used in the distant past on a car where the real problem was later found to be a seizing up idler pulley. Spray didn't help then and just made a mess to play in.

The other silly thought I had - do you have a tool in the spindle or is the drawbar just loose?

As for spray - I can't recommend any. I've only used in the distant past on a car where the real problem was later found to be a seizing up idler pulley. Spray didn't help then and just made a mess to play in.

Actually, I think you may have pointed to a clue. No resonance in low, and only there in high. I had a resonance on my surface grinder, was the Lovejoy coupler had aged and allowed just enough slop to have a resonance develop between the motor and grinding spindle. I wonder if there is a similar phenomenon going on with the dog teeth? Can you access it? Maybe try putting a bit of grease in it and see if it changes the resonance for a little bit?

The other check would be to put a load (drag) on the spindle. If under a load the resonance is gone or changes when it occurs, could be due to slop in the dogs.

The other check would be to put a load (drag) on the spindle. If under a load the resonance is gone or changes when it occurs, could be due to slop in the dogs.

I do have an optical RPM sensor gun style. Haven't used in a while but I think it just needs a contrast stripe of some sort. In a very crude way (I think) LEDs on flashlights must somehow flash on/off at some high frequency because by varying the RPMS up to a level I can make the belt 'stand still' or eek forward or reverse from stationary by just nudging rpm wheel either way. So, at least at that RPM seems quite constant from a motor belt speed standpoint. But the gun would be a better tool.

For this last run-in, chuck/drawbar is in drawbar & tightened & jaws closed. Before this episode I've had bot out with identical resonance.

In terms of load/drag all I can say is while running the machine in what I preferred at a cutting RPM, say 1000, it was the same harmonic racket cutting vs just spinning. I never tested under a super heavy load.

For this last run-in, chuck/drawbar is in drawbar & tightened & jaws closed. Before this episode I've had bot out with identical resonance.

In terms of load/drag all I can say is while running the machine in what I preferred at a cutting RPM, say 1000, it was the same harmonic racket cutting vs just spinning. I never tested under a super heavy load.

In low rpm mode (lower picture) = no noise foreword or reverse. Dogs are disengaged. But both belts are still engaged & a new gear 83 becomes engagedActually, I think you may have pointed to a clue. No resonance in low, and only there in high. I had a resonance on my surface grinder, was the Lovejoy coupler had aged and allowed just enough slop to have a resonance develop between the motor and grinding spindle. I wonder if there is a similar phenomenon going on with the dog teeth? Can you access it? Maybe try putting a bit of grease in it and see if it changes the resonance for a little bit?

In high rpm mode (top picture) = noise in forward, but not in reverse. Dogs are engaged regardless of motor direction. Gear 83 is disengaged. One would think if a noise in one direction due to backlash, should be similar spinning opposite direction with no other changes to system. Unless badly or preferentially worn dog teeth. But they looked brand new & fit very tight, we tested that. And well grease lubricated.

Another thing I forgot to mention. I gave the spring a push & then a mild tap with with screwdriver. That bugger is so stiff & strong & under so much compression its not going anywhere. I was wondering if it was doing the funky harmonic maybe in more un-sprung range, but that defies logic with harmonic at a certain RPM. So I no longer think so. I feel the noise is coming from belt area. Now if you tap the spring it makes an unsupported tuning fork resonant tone as one would expect vs a thud on a shaft or casting. Its hard to reach. I can just view it while running through the side vent hole.

Attachments

historicalarms

Ultra Member

Methinks if what your looking for is that hard to pinpoint it probably is inconsequential and best ignored...a common practice with industrial & heavy trucks....just turn the radio up louder to drown out and carry on.

140mower

Don

I've repaired a couple car mufflers in the same manner in my younger days. 🙄...a common practice with industrial & heavy trucks....just turn the radio up louder to drown out and carry on.

But yup, it's often the only way to fix a dash squeak ....