-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

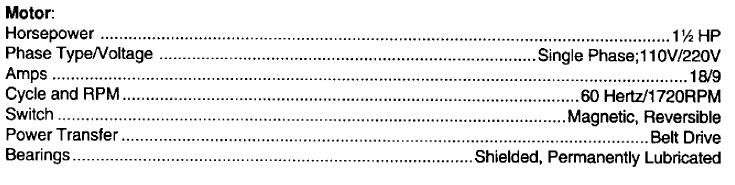

Possible candidate for 3-phase for my lathe?

- Thread starter David

- Start date

Oh maybe I'm wrong about the motor....maybe it's not 1.5hp. In fact I'm not sure where I got that figure. <shrug/>I'm glad you got it. I'm sure that it would easily drive your lathe. I'm still on the original 3/4 hp original motor.- weak, but it works...

Edit I got it from the Grizzly manual for their version of the BB 1237G lathe. Is mine actually 1.5 hp. I have no idea TBH. I guess I'll find out when I pull it away from the wall to install the Z axis DRO and do the motor swap.

Last edited:

Oh maybe I'm wrong about the motor....maybe it's not 1.5hp.

I wouldn't put that particular motor on your lathe anyway. It would be a waste. Better to get the right 3ph motor (w 20% more HP than stock) and a good VFD for your lathe and save that crown jewel for the right application - or sell it to me.......

Dan Dubeau

Ultra Member

Nice find. Now you need to pickup another project to stick it on 😀.

I'm going to convert the lathe.Nice find. Now you need to pickup another project to stick it on 😀.

Dan Dubeau

Ultra Member

Nice, Now you need to pickup another project to stick the old lathe motor on......🙂

I have a small stash of 1.Xhp single phase motors. Need a bunch of projects to put them on!Nice, Now you need to pickup another project to stick the old lathe motor on......🙂

Dan Dubeau

Ultra Member

I shall adjust my marketplace and kijiji radius to help you out 😀

This is the manual for the VFD.

Looking at the Fig. 3-21 on pg. 47 of the pdf I believe a 5K pot across terminals J-1, 2 and 3 will give me speed control and a SPDT switch between J 8, 9 and 10 will give me fwd/off/rev.

If someone could check my thinking I'd be grateful.

Looking at the Fig. 3-21 on pg. 47 of the pdf I believe a 5K pot across terminals J-1, 2 and 3 will give me speed control and a SPDT switch between J 8, 9 and 10 will give me fwd/off/rev.

If someone could check my thinking I'd be grateful.

Attachments

If someone could check my thinking I'd be grateful.

I tried checking for you David, but the PDF is incomplete on my end. I wanted to read pg 3-47 regarding analog inputs and couldn't find it.

In general that's how my Teco works.

Thinking for connections looks okay.

Are you looking at using a rocker switch, toggle switch, rotary switch, drum switch? I've used the original drum switch on the lathe and have a rotary on the mill both work well. A standard size toggle or rocker might be a bit small for comfort.

Are you looking at using a rocker switch, toggle switch, rotary switch, drum switch? I've used the original drum switch on the lathe and have a rotary on the mill both work well. A standard size toggle or rocker might be a bit small for comfort.

The notes say momentary for the forward reverse and a separate NC button for stop.This is the manual for the VFD.

Looking at the Fig. 3-21 on pg. 47 of the pdf I believe a 5K pot across terminals J-1, 2 and 3 will give me speed control and a SPDT switch between J 8, 9 and 10 will give me fwd/off/rev.

If someone could check my thinking I'd be grateful.

so you have a momentary button you press to make it go forward and then a NC momentary that you press to stop the motor.

These are NO

Or go this way momentary in either direction for forward/reverse

This one for the stop switch since it has NC contacts.

Put this one on Terminal 8 for the ENABLE.

You could also have that one instead control a contactor with an extra pole that does the enable.

Right. I forgot it said momentary switches. I may have momentary switches now because there is at least one contactor in the existing electrical box now.The notes say momentary for the forward reverse and a separate NC button for stop.

so you have a momentary button you press to make it go forward and then a NC momentary that you press to stop the motor.

I edited my post with PA links to switches. I use those on all my stuff.Right. I forgot it said momentary switches. I may have momentary switches now because there is at least one contactor in the existing electrical box now.