-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

One Man's Junk is another man's Treasure

- Thread starter Dusty

- Start date

@6.5 Fan , @Susquatch & @slow-poke posts 16, 19 & 22 refer to 3ph motor and/or VFD

My being slow on the take-up as it relates to electrical changes would someone kindly explain what this process does and the reasons as to why. Sorry guys this went right over old Dusty's head and right out the window.

Be gentle with your replys.

Dusty

My being slow on the take-up as it relates to electrical changes would someone kindly explain what this process does and the reasons as to why. Sorry guys this went right over old Dusty's head and right out the window.

Be gentle with your replys.

Dusty

Last edited:

@6.5 Fan , @Susquatch & @slow-poke posts 16, 19 & 22 refer to 3ph motor and/or VFD

My being slow on the pick up as it relates to electrical changes would someone kindly explain what this process does and the reasons as to why. Sorry guys this went right over old Dusty's head and right out the window.

Be gentle with your replys.

Dusty

Typically you use a VFD to convert 220V single phase to 220V three phase. The VFD allows the frequency of the 220V three phase side of the VFD to be varied, causing the three phase motor to run at different RPMs. I converted my RF30 and haven't changed a belt since.

Do you have 220V single phase available in your shop?

Typically you use a VFD to convert 220V single phase to 220V three phase. The VFD allows the frequency of the 220V three phase side of the VFD to be varied, causing the three phase motor to run at different RPMs. I converted my RF30 and haven't changed a belt since.

Do you have 220V single phase available in your shop?

There are also 120v to 240v 3-phase VFDs

Hey Craig & @David_R8 , for me the door is slowly opening. LOL

Yes I do have 220 single phase into my garage/shop although only a single outlet.

If I understand what you are saying and I believe I do, one doesn't change out the motor or V belt system it all come obout with some sort of converter between the single phase power source and the motor.

Ok then, what kind of investment am I looking at? Where should I look on line for such a converter unit?

Where would you purchase same?

Fill me in on the set up you use, photos please they would really help. Keep it coming guys.

Like opening a can of worms. LOL

Dusty

Last edited:

Let me know if you need more info @Dusty. I enjoy explaining such things at whatever level is needed.

By all means Susquatch keep the info coming.

Like opening a can of worms. LOL

It's a lovely can of worms Dusty. You will need to get a 3ph motor too. That will give you everything you want as well as smoothness, braking, and torque. You will love it. I'll never go back. I'll be doing my lathe soon.

Essentially you find a 3-phase motor of the appropriate size. All the advice I read was to up-size the motor to account for loss of torque at lower speeds. My mill had a 1hp motor so I went with a 1.5 hp 3-phase. The a VFD of sufficient rating for the motor. I'm partial to Teco VFDs but they are spendy. I know other have had good luck with import VFDs. I'm on the fence with them.Hey Craig & @David_R8 , for me the door is slowly opening. LOL

Yes I do have 220 single phase into my garage/shop although only a single outlet.

If I understand what you are saying and I believe I do, one doesn't change out the motor or V belt system it all come obout with some sort of converter between the single phase power source and the motor.

Ok then, what kind of investment am I looking at? Where should I look on line for such a converter unit?

Fill me in on the set up you use, photos please they would really help. Keep it coming guys.

Like opening a can of worms. LOL

Dusty

The controls on my mill were dead simple because that's all I could comprehend. I had a 10K potentiometer for speed( frequency) control and a 2-way switch for forward/off/reverse.

It's a lovely can of worms Dusty. You will need to get a 3ph motor too. That will give you everything you want as well as smoothness, braking, and torque. You will love it. I'll never go back. I'll be doing my lathe soon.

This is beginning to sould like a major out lay of finances. Wow!

Induction Motor specs from the mfgs plate (China)

1.5 HP, PH1 (120 v- 220v) - Pole 4, Amp.21 - 10.5, RPM 1700

Last edited:

It depends. I can never find the used 3-phase motors here so I had to buy new. I think that was like $300 (prepandemic) I buy my motors from e-motorsdirect.ca.This is beginning to sould like a major out lay of finances. Wow!

I will buy from them when I convert my lathe to 3-phase.

By all means Susquatch keep the info coming.

Here is a bit more info then that adds to what @YYCHM and @David_R8 said.

Most residential electrical systems in Canada are 230V Single Phase 60Hz systems with a neutral. The neutral splits the 230 into two 115V supplies. But still single phase 60Hz.

With a single phase service, you would normally be required to use a single phase motor - either 230 or 115.

Most motors are designed to run at the input frequency. So a normal 60Hz motor will generally run at 1780 rpm with two windings. (The exact math is 3600 and 1800 but a certain loss called slip is required to produce torque.)

So the best way to change their speed is to change the input frequency.

VFDs convert single phase to DC and then from that to a variable frequency output. This allows (or forces) the motor to turn at variable speeds.

It's difficult to make a single phase motor run at variable speeds because of the start coil, centrifugal switch, and capacitor(s). They like to produce magic smoke when run outside their design speeds.

3 phase motors do not have start windings, switches, or capacitors and can be run at variable speeds. The range of speeds depends on the motor design and ratings, it's best to get vfd rated motors because they have the widest operating range. But even a non rated motor can usually be run as low as 40hz and as high as 75.

All the advice I read was to up-size the motor to account for loss of torque at lower speeds.

Hmmm.... I think you mixed the terms David. For most VFDs, there is no loss of torque at lower speeds. However, there is a loss of HP. Similarly, at high rpm there is a loss of Torque but no loss of HP.

Lots of arguments from lots of knowledgeable sources debate these merits. Personally, I didn't upsize my mill motor and am very happy. I might have lost a little chip load as the rpm drops, but it still cuts like butter at full torque. However, I did upsize my lathe motor from 2 HP to 2.4HP mostly because the startup loads on a lathe are a killer and the VFD will allow me to program in a startup acceleration to protect my gear train.

One thing that hasn't been mentioned @Dusty is that the smoothness of a VFD 3ph motor system has to be seen and felt to be believed. Simply amazing!

Last edited:

This is beginning to sound like a major out lay of finances. Wow!

Doesn't have to be.....

RF30 Basement Install

So after much dithering I finally decided to convert my mill to 3 phase with VFD speed control. Pretty much have everything I need now 2 HP 3 PH motor $60 from Kijiji 4 HP VFD $75 from Amazon ESD switch $18 from BB 12' of 14AWG 4 strand electrical cord $23 from Home Depot I was going to...

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

@Dusty - Used 3ph motors can be had for $20 to $50 with patience. A few months ago I bought 2 brand new take-off motors one 2hp and one 5hp for $50 each. They had been on Kijiji for months with no interest.

You can get a low cost VFD on Ali too. I decided to go with Teco which was expensive but not compared to the benefits to my machines.

You can get a low cost VFD on Ali too. I decided to go with Teco which was expensive but not compared to the benefits to my machines.

@Dusty - Used 3ph motors can be had for $20 to $50 with patience. A few months ago I bought 2 brand new take-off motors one 2hp and one 5hp for $50 each. They had been on Kijiji for months with no interest.

You can get a low cost VFD on Ali too. I decided to go with Teco which was expensive but not compared to the benefits to my machines.

So what kind of investment would I be looking at meaning low to high.

So what kind of investment would I be looking at meaning low to high.

All used stuff maybe 100. Best of best over a 1000.

slow-poke

Ultra Member

Dusty,

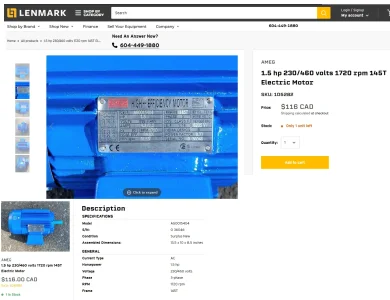

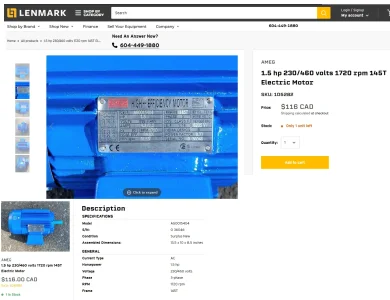

I was so happy with the three phase motor and VFD that I added to my old mill, it's the first mod I'm doing to my new mill. Being impatient this time around I opted to purchase new surplus from Lenmark for $116 not sure where you are located, Lenmark is in Langley and they have a lot of new, used , surplus etc. This is my first purchase from them so at this point all I have is a tracking # , hopefully the motor turns out to be good.

Kijiji etc can be a good source for a used bargain, but it may take a while to find what you want.

The important things to look for are (and can all be found on the nameplate):

+ HP

+ RPM (match what you have, likely 1700-1800)

+ Frame (match what you have)

+ Voltage 220-240 (often these motors have wiring to accommodate multiple voltages just make sure it includes an option for 230V)

+ 3 Phase

For the VFD, I have a great success with Altivar brand. I did try a generic Amazon style one for my drill press and it worked great for a while but then died. I found another Altivar on eBay for about $50 used I'm going to use that for my new mill.

Single phase motors have two wires plus a ground, three phase motors have three wires plus a ground.

When using a VFD, not only do you get variable speed, but also dynamic braking that can wind down the spindle very quickly. The really cheap VFD's don't have a feature called torque compensation that allows for more torque at slow speeds, this was important for me because when drilling really big holes I like to turn the speed way down.

Another note, there is a fair bit of chat about only using inverter rated motors with a VFD. I'm not and expert but from my limited experience and from what I have read here is the skinny on that topic:

compared to regular sinusoidal power that we get from the utility, the VFD produces a less than perfect waveform. The less than perfect waveform = some harmonics, greater voltage deviations etc. When using small motors 1.5-2HP @230V with less than perfect power the inverter rated hooplah is overrated because the 230V motor has 600V wire in it anyways etc. Now for larger motors for example 10HP and 600V operation than an inverter rated motor is probably a wise investment. I have been running a regular (very used) non inverter rated motor that came out of a commercial dryer for several years now and it's running like a champ, and from what I have read this is typical.

I was so happy with the three phase motor and VFD that I added to my old mill, it's the first mod I'm doing to my new mill. Being impatient this time around I opted to purchase new surplus from Lenmark for $116 not sure where you are located, Lenmark is in Langley and they have a lot of new, used , surplus etc. This is my first purchase from them so at this point all I have is a tracking # , hopefully the motor turns out to be good.

Kijiji etc can be a good source for a used bargain, but it may take a while to find what you want.

The important things to look for are (and can all be found on the nameplate):

+ HP

+ RPM (match what you have, likely 1700-1800)

+ Frame (match what you have)

+ Voltage 220-240 (often these motors have wiring to accommodate multiple voltages just make sure it includes an option for 230V)

+ 3 Phase

For the VFD, I have a great success with Altivar brand. I did try a generic Amazon style one for my drill press and it worked great for a while but then died. I found another Altivar on eBay for about $50 used I'm going to use that for my new mill.

Single phase motors have two wires plus a ground, three phase motors have three wires plus a ground.

When using a VFD, not only do you get variable speed, but also dynamic braking that can wind down the spindle very quickly. The really cheap VFD's don't have a feature called torque compensation that allows for more torque at slow speeds, this was important for me because when drilling really big holes I like to turn the speed way down.

Another note, there is a fair bit of chat about only using inverter rated motors with a VFD. I'm not and expert but from my limited experience and from what I have read here is the skinny on that topic:

compared to regular sinusoidal power that we get from the utility, the VFD produces a less than perfect waveform. The less than perfect waveform = some harmonics, greater voltage deviations etc. When using small motors 1.5-2HP @230V with less than perfect power the inverter rated hooplah is overrated because the 230V motor has 600V wire in it anyways etc. Now for larger motors for example 10HP and 600V operation than an inverter rated motor is probably a wise investment. I have been running a regular (very used) non inverter rated motor that came out of a commercial dryer for several years now and it's running like a champ, and from what I have read this is typical.

Last edited:

@Dusty, I have 4 machines that run off VFD. I did this because of two main factors. On the mills, I didn't like changing belts, but my vari-head mill also runs on the VFD. That's because the speed control is far more convenient, and it has a far wider range, ans the RPM is displayed on the VFD. And torque on a mill is less important than on a lathe...

On the surface grinder, I use it to safely use wheels that are out of balance or otherwise needing slower speeds. I'm a hobby guy, so grinding fast isn't in my playbook.

---

If you can get a used motor, you can spend as little or as much as you like. I have several 3PH 20$ motors on the shelf. It is recommended to use a VFD ready motor, and that is good, but none of my motors are VFD rated. The concern about insulation, etc only is an issue at the high end of performance for the motor, such as rapid acceleration under load and braking.

For an inexpensive VFD, the prices are 40-80$ for 1HP, and sliding scale upwards. I am considering an offshore VFD for my 7.5HP lathe.

For a name brand VFD, (TECO, Hitachi, etc) expect to pay 350$CDN for a base model 1HP vfd. It goes up fast from there, and one for my 7.5 is north of 1900$CDN, way too much for my taste.

Keep in mind these offshore VFDs have brought the name brand ones down by over half the price, and that trend will continue IMO.

Other costs will include proper enclosures, cabling, in my case, connectors. My first mill VFD project was north of 550$, and I had the motor already. The additional machines were added at about $80 each. -Yes, I move my VFD around to several machines. They all have the same nominal current value (within 20%), so this actually works very well. The rest of the VFD's performance comes by measuring the motor performance in real time anyway.

On the surface grinder, I use it to safely use wheels that are out of balance or otherwise needing slower speeds. I'm a hobby guy, so grinding fast isn't in my playbook.

---

If you can get a used motor, you can spend as little or as much as you like. I have several 3PH 20$ motors on the shelf. It is recommended to use a VFD ready motor, and that is good, but none of my motors are VFD rated. The concern about insulation, etc only is an issue at the high end of performance for the motor, such as rapid acceleration under load and braking.

For an inexpensive VFD, the prices are 40-80$ for 1HP, and sliding scale upwards. I am considering an offshore VFD for my 7.5HP lathe.

For a name brand VFD, (TECO, Hitachi, etc) expect to pay 350$CDN for a base model 1HP vfd. It goes up fast from there, and one for my 7.5 is north of 1900$CDN, way too much for my taste.

Keep in mind these offshore VFDs have brought the name brand ones down by over half the price, and that trend will continue IMO.

Other costs will include proper enclosures, cabling, in my case, connectors. My first mill VFD project was north of 550$, and I had the motor already. The additional machines were added at about $80 each. -Yes, I move my VFD around to several machines. They all have the same nominal current value (within 20%), so this actually works very well. The rest of the VFD's performance comes by measuring the motor performance in real time anyway.