-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nut on dead center

- Thread starter PeterT

- Start date

Dan Dubeau

Ultra Member

It's for when you need to center something dead nuts....

I'd say extraction.

Tom Kitta

Ultra Member

I have a center like that with threads.

royalproducts.com

royalproducts.com

nut deals with extraction.

"

lathe tailstocks lack a through hole to aid in knocking the dead center out of the tailstock. Tailstock pressures in dead center turning applications are also considerably higher than that normally used in grinding. The lack of a through hole coupled with the high tailstock pressure can literally lock the center into the tailstock making it very hard to remove. CNC dead centers are threaded to allow the use of a take off nut to help remove the center from the tailstock. The nut bottoms against the face of the tailstock as it is threaded over the center. Since the nut can’t move axially, forcing the nut to turn with a wrench draws the center out of the tailstock.

"

Royal Threaded Dead Centers – Royal Products

nut deals with extraction.

"

lathe tailstocks lack a through hole to aid in knocking the dead center out of the tailstock. Tailstock pressures in dead center turning applications are also considerably higher than that normally used in grinding. The lack of a through hole coupled with the high tailstock pressure can literally lock the center into the tailstock making it very hard to remove. CNC dead centers are threaded to allow the use of a take off nut to help remove the center from the tailstock. The nut bottoms against the face of the tailstock as it is threaded over the center. Since the nut can’t move axially, forcing the nut to turn with a wrench draws the center out of the tailstock.

"

Rauce

Ultra Member

I’ve always seen them described as CNC dead centers.

I do think it would be handy for a headstock dead center since it saves having to awkwardly tap on a bar through the spindle to get it out while trying not to let it fall onto something.

If I could find one in MT5 at a reasonable price I’d get it for that purpose.

I do think it would be handy for a headstock dead center since it saves having to awkwardly tap on a bar through the spindle to get it out while trying not to let it fall onto something.

If I could find one in MT5 at a reasonable price I’d get it for that purpose.

About $50 will get an offshore from many suppliers. Add a grand if you want a Royal. Threaded aren't as common on KBC which is why I was asking. Just so happened to be looking on Ebay which is where my pics came from. I'm pretty sure I could tap mine out through the headstock spindle tube. I'll have to check if the thread would play nice with the face plate or dog drive plate. Right now I use an MT3 with an MT5/MT3 sleeve which came with the lathe.

www.kbctools.ca

www.kbctools.ca

Results Page 1 :: KBC Tools & Machinery

When I bought my South Bend Heavy 10L it did not come with a dead centre. I learned from the South Bend group that the taper of the headstock was non-standard. Or you could say it was standard South Bend Heavy 10L.

Anyway, from one of the group members, I bought an adapter to MT-3.

My only complaint about it is that the MT-3 extends out too far. Would have been nice if the internal MT-3 taper had been larger. I'm not sure this part is hardened and although I turn between centres a fair bit I've not been bothered to try and fix it or create a new adapter.

Anyway, from one of the group members, I bought an adapter to MT-3.

My only complaint about it is that the MT-3 extends out too far. Would have been nice if the internal MT-3 taper had been larger. I'm not sure this part is hardened and although I turn between centres a fair bit I've not been bothered to try and fix it or create a new adapter.

Attachments

Rauce

Ultra Member

I’m using a mt3 in a sleeve right now. I think if I’m going to bother getting a mt5 (slightly better runout hopefully) I’d get one with threads. The threaded ones tend to cost more.About $50 will get an offshore from many suppliers. Add a grand if you want a Royal. Threaded aren't as common on KBC which is why I was asking. Just so happened to be looking on Ebay which is where my pics came from. I'm pretty sure I could tap mine out through the headstock spindle tube. I'll have to check if the thread would play nice with the face plate or dog drive plate. Right now I use an MT3 with an MT5/MT3 sleeve which came with the lathe.

Results Page 1 :: KBC Tools & Machinery

www.kbctools.ca

There’s nothing stopping me from tapping it out through the headstock, I’d just prefer to use a nut.

S

I don't know your lathe (and actually I have to go back & check my own) but wondering out loud here. It might appear to stick out too far with no other accessory mounted to on the spindle. But once you mount a drive plate or face plate in order to drive the dog, it could be that the dead center would also have to protrude more in order to engage the work? My lathe is D1-4 so I'm not quite sure what I'm looking at on your 10L picture.My only complaint about it is that the MT-3 extends out too far.

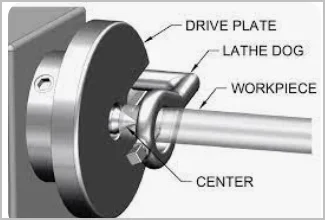

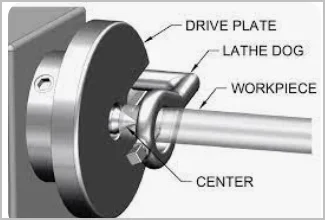

I'm usually so wordy. But this time I think the picture is worth 1000 words.S

I don't know your lathe (and actually I have to go back & check my own) but wondering out loud here. It might appear to stick out too far with no other accessory mounted to on the spindle. But once you mount a drive plate or face plate in order to drive the dog, it could be that the dead center would also have to protrude more in order to engage the work? My lathe is D1-4 so I'm not quite sure what I'm looking at on your 10L picture.

View attachment 35618

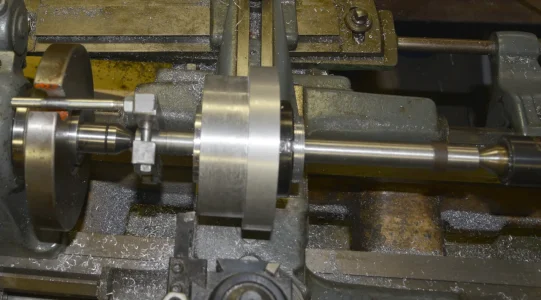

I use a home made drive. Should really make the pin thicker.

It's already on my list. Project #42.You appear to have a taper attachment. Just make a couple of stubby dead centers. That's what I did.

View attachment 35621

a smile

Lifelong hobby - cold iron

You appear to have a taper attachment. Just make a couple of stubby dead centers. That's what I did.

View attachment 35621

- This is where the thread needs to be. Why not?

I didn't need the extraction nut. I needed a stubby dead center that didn't protrude out the drive plate too far like this one...

Note the lathe dog doesn't engage the drive plate. The dead center is too long.

Last edited:

In essence that's what I did by making a dog with a longer arm. But I think in reality the idea of a shorter dead center is the best idea. I found the long shaft I used for turning the pulleys really flexed too much.I’d just make a sleeve to slide over the dog.