Gearhead88

Ultra Member

Is there a book ? VFD's for dummies ?

I have questions .............

In my shop , there is one 208 v wall outlet , fed from a double pole 20 amp breaker in the panel , What ever machine I happen to be running gets plugged in , I only run one thing at a time .

I have a 12 x 36 lathe , another mill & two welding machines that share the same wall outlet .

This brings up the first question ...........

A VFD requires programing ? , I'm making assumptions here but the VFD will need some parameters set ? , or not ?? .

This machine is going to be plugged in only when I'm using it ............

Will the saved settings that get programed into the VFD be lost when it is unplugged ? .

Next question ..........

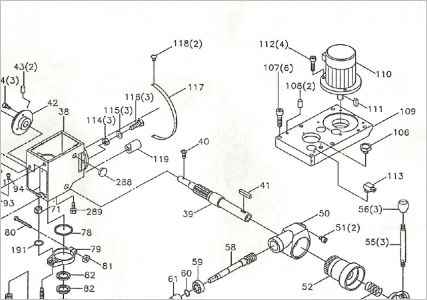

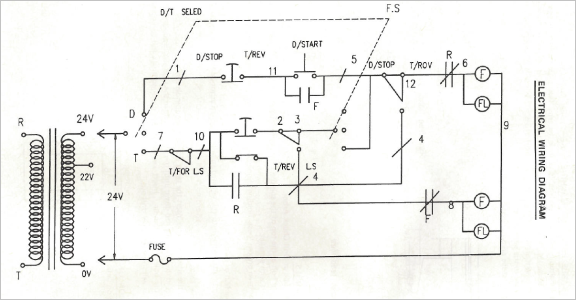

I would like to retain the use of the switches on the front panel of the mill , is that possible ? . I should mention , in a box on the back of the machine , there's a transformer that steps 208 down to 24 volts for the control circuit , it almost looks like this is an ad on that was done after the machine was built . I do not have a wiring diagram for this machine and I'm not sure it is original , unmolested or butchered .

I have questions .............

In my shop , there is one 208 v wall outlet , fed from a double pole 20 amp breaker in the panel , What ever machine I happen to be running gets plugged in , I only run one thing at a time .

I have a 12 x 36 lathe , another mill & two welding machines that share the same wall outlet .

This brings up the first question ...........

A VFD requires programing ? , I'm making assumptions here but the VFD will need some parameters set ? , or not ?? .

This machine is going to be plugged in only when I'm using it ............

Will the saved settings that get programed into the VFD be lost when it is unplugged ? .

Next question ..........

I would like to retain the use of the switches on the front panel of the mill , is that possible ? . I should mention , in a box on the back of the machine , there's a transformer that steps 208 down to 24 volts for the control circuit , it almost looks like this is an ad on that was done after the machine was built . I do not have a wiring diagram for this machine and I'm not sure it is original , unmolested or butchered .