Been wanting a bigger and better cut off bandsaw for some time, and the last while I’ve been getting into bigger material, so decided it was time to upgrade from the little 4x6 import.

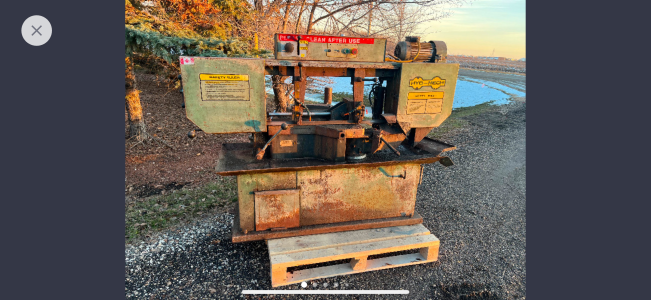

So, weather pending, I’m headed about 1100 kms to Winnipeg area to pick up a Hyd-Mech S20 this coming weekend.

The downside of this addition to the shop is the fact that it looks more and more like a major re-arranging has to happen to make it all fit.

Going from 4x6 to 13x18 is going to be a game changer here in the shop.

So, weather pending, I’m headed about 1100 kms to Winnipeg area to pick up a Hyd-Mech S20 this coming weekend.

The downside of this addition to the shop is the fact that it looks more and more like a major re-arranging has to happen to make it all fit.

Going from 4x6 to 13x18 is going to be a game changer here in the shop.