I have a spool of that stuff but I've never user it...Now that ability to print supports in a different material is a cool feature.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New printer

- Thread starter jcdammeyer

- Start date

I'm going to load my spool of PETG after the printer is free and try and print something with support 'levels' not just support. The difference is the special filament is only used for a couple of layers.I have a spool of that stuff but I've never user it...

If I understand correctly it does add print time because of the filament changeover. Or I may be completely mistaken 🙂I'm going to load my spool of PETG after the printer is free and try and print something with support 'levels' not just support. The difference is the special filament is only used for a couple of layers.

Oh yes. And it goes through filament. That's to be expected with any single nozzle change over. Wouldn't have been a problem with my POS Delta as it has two nozzles although aligning the two and the subsequent problems introduced other issues.If I understand correctly it does add print time because of the filament changeover. Or I may be completely mistaken 🙂

But given the expense of this support stuff why not use regular PLA or PETG and only use the special support filament for the boundary area. Such a cool idea.

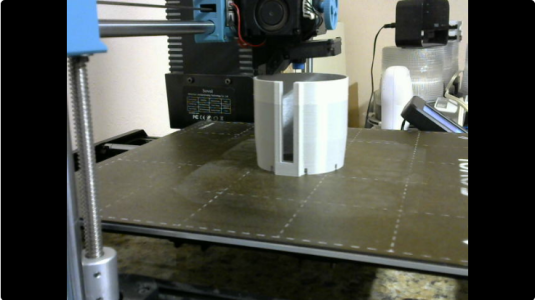

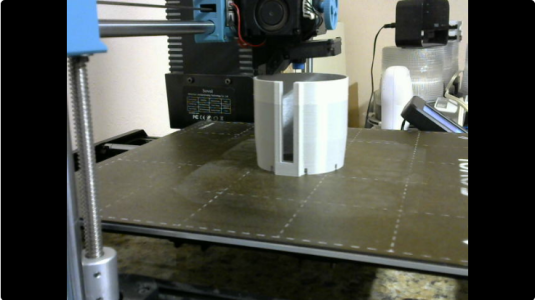

What is happening here are small bits of filament that drop off and add to the surface. On the P1S (X1 too) you should enable the Prime Tower. Now if you don't have an AMS, then after enabling Prime Tower, select with the dropdown, Timelapse - SMOOTH. This will force the tower and remove most of those zits too.One thing I don't understand is why the support filament bubbled up (or gobbed) in a couple of places. Those bumps were reflected in the layers laid on top of it.

View attachment 55311

Here it looks like the PLA under where the support will go has perhaps also a bit of a glitch.

View attachment 55312

They are very nice machines, and yes the shipment centre is Vancouver.

You can also try tree supports, which sometimes solve problems. The 'on build plate only' option is worth looking at depending upon the design.

When changing filaments, you can flush into infill to save filament and time. Don't do this with support filament. Saved many hours on a complex multicolor print with this setting.

When changing filaments, you can flush into infill to save filament and time. Don't do this with support filament. Saved many hours on a complex multicolor print with this setting.

Doggggboy

Ultra Member

I printed the anatomically correct full sized human skull with tree supports and the only problem was getting them out of some of the smaller nasal cavities.You can also try tree supports, which sometimes solve problems. The 'on build plate only' option is worth looking at depending upon the design.

When changing filaments, you can flush into infill to save filament and time. Don't do this with support filament. Saved many hours on a complex multicolor print with this setting.

So I guess, yes, it printed with boogers.

Why did you have to remove support at all ? So many people anatomically have only support for the ears in their skull and nothing else. 🙂I printed the anatomically correct full sized human skull with tree supports and the only problem was getting them out of some of the smaller nasal cavities.

Doggggboy

Ultra Member

Realism.Why did you have to remove support at all ? So many people anatomically have only support for the ears in their skull and nothing else. 🙂

An empty skull seemed fitting.

Oh my gosh.

Just changed over a light grey spool as it ran out through the filament sensor. I was all prepared with another grey one. Supposed to be the same light grey but this one is a bit lighter.

What's weird though is other than the box and little fittings parts for the compressor monitor along with two small boxes for the gear cutter sets I can't for the life of me remember or find anything else I 3D printed in that light grey. What I did print wouldn't have used an entire spool.

Very strange.

Just changed over a light grey spool as it ran out through the filament sensor. I was all prepared with another grey one. Supposed to be the same light grey but this one is a bit lighter.

What's weird though is other than the box and little fittings parts for the compressor monitor along with two small boxes for the gear cutter sets I can't for the life of me remember or find anything else I 3D printed in that light grey. What I did print wouldn't have used an entire spool.

Very strange.