-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Milling Machine - Craftex CX-601

- Thread starter SomeGuy

- Start date

@SomeGuy - A couple of things about DROs that I learned in my quest.

Many will suggest that 1 micron is not necessary. 5 or even 10 is fine. I agree with that. However, if you can get it thrown in, then why not? It's just a different magnet or different etching in the scales and basically zero cost to the seller. On the Ditron you can turn off the digits in the display which then rounds off the extra digits in the background. No, it does not truncate, it averages - I checked. Even if you don't use it, the fact that it exists in the background gives me MUCH more confidence in the numbers I do see.

Similarly, glass scales are fine, but I believe magnetic is actually easier to manufacture and should be cheaper, but isn't. Again, if you can get it thrown in, why not? It is the newer technology. Plus, magnetic is super easy to shorten if you need to. Glass is easy too but it does have a certain "pucker factor". Most users cut it just fine. Is so they are golden. But if not...... It cannot be fixed - only replaced. That's how I looked at it anyway. DROPros pretty much convinced me to go magnetic.

I also followed their directions for measuring. Watching a video for that was painful, but it did give me confidence. And I am happy with the results.

I don't personally like the kit brackets. So I made my own that you can see in my install thread. The most difficult one was the X axis. Not because my table was made of undrilobillium, but because I had no X-Axis dro yet! Once the X-Axis was done and turned on, I used it to make the rest of the brackets. I must say that the first working axis was like a cold drink of water after a hot day in the desert. OMG, I couldn't believe how much easier things became. Just locating the tiny screw holes for the read head alone was an amazing experience. So was switching back and forth between metric and imperial. Put the conversion calculator away - you don't need it anymore.

Lastly, I did what @Tom O suggests above, and added a 4th axis for my Quill. You can leave the quill and Z as separate Readouts, or the unit can be programmed to combine them into one reading for both. Again, the additional cost for Ditron is peanuts. So if you can get it thrown in, why not?

I do confess my RPM is not working yet. I have to take my mill head apart to install the sensor so it has to wait a while. I had to think long and hard about what I really wanted. An rpm/sfm Readout ala @whydontu or just rpm. I decided that both was feasible so why not? There is something to be said for all the Readouts in one place. But there is also something to be said for programmable rpm functionality. When I take my head apart, I plan to install several sensors so I can use both systems. It's overkill, but..... Why not?

Life is GREAT!

Many will suggest that 1 micron is not necessary. 5 or even 10 is fine. I agree with that. However, if you can get it thrown in, then why not? It's just a different magnet or different etching in the scales and basically zero cost to the seller. On the Ditron you can turn off the digits in the display which then rounds off the extra digits in the background. No, it does not truncate, it averages - I checked. Even if you don't use it, the fact that it exists in the background gives me MUCH more confidence in the numbers I do see.

Similarly, glass scales are fine, but I believe magnetic is actually easier to manufacture and should be cheaper, but isn't. Again, if you can get it thrown in, why not? It is the newer technology. Plus, magnetic is super easy to shorten if you need to. Glass is easy too but it does have a certain "pucker factor". Most users cut it just fine. Is so they are golden. But if not...... It cannot be fixed - only replaced. That's how I looked at it anyway. DROPros pretty much convinced me to go magnetic.

I also followed their directions for measuring. Watching a video for that was painful, but it did give me confidence. And I am happy with the results.

I don't personally like the kit brackets. So I made my own that you can see in my install thread. The most difficult one was the X axis. Not because my table was made of undrilobillium, but because I had no X-Axis dro yet! Once the X-Axis was done and turned on, I used it to make the rest of the brackets. I must say that the first working axis was like a cold drink of water after a hot day in the desert. OMG, I couldn't believe how much easier things became. Just locating the tiny screw holes for the read head alone was an amazing experience. So was switching back and forth between metric and imperial. Put the conversion calculator away - you don't need it anymore.

Lastly, I did what @Tom O suggests above, and added a 4th axis for my Quill. You can leave the quill and Z as separate Readouts, or the unit can be programmed to combine them into one reading for both. Again, the additional cost for Ditron is peanuts. So if you can get it thrown in, why not?

I do confess my RPM is not working yet. I have to take my mill head apart to install the sensor so it has to wait a while. I had to think long and hard about what I really wanted. An rpm/sfm Readout ala @whydontu or just rpm. I decided that both was feasible so why not? There is something to be said for all the Readouts in one place. But there is also something to be said for programmable rpm functionality. When I take my head apart, I plan to install several sensors so I can use both systems. It's overkill, but..... Why not?

Life is GREAT!

But I also have a boat! Oh oh.Years ago, someone asked me how I justified building a bigger garage than needed to fit our cars. I replied by asking him to first justify his boat. The discussion ended there.

OBMetal: first fire in the new workshop/forge yesterday. And the reminder that rebar can be terrible - twisting a little utility handle square a little too cold and it just snapped - the grain was at least 0.25mm without having quenched it. I'm guessing there are a lot of "interesting" toyota parts in that piece of scrap bar. And I have a lot of it lying around after the build.

I'll snap some new shop pictures and add them to my thread later today.

That's rather shocking. This the one you're looking for a donor frame for?Hey, watch the dissing of Yota's! LOL😀

In your defense, some yota's don't have a lot of metal left to scrap.

View attachment 24787

DRO/CNC??? - I’m about to plunge into milling- I’ve never cut a chip on a mill before. I’m confused. Like SomeGuy - I’ll have to do some more learning/research/thinking.

I thought a mill with a DRO would be a great start. Then I’d learn the basic and maybe (?) upgrade to CNC. But I don’t have any plans to go CNC. Starting with a CNC mill seems like jumping into the deep end and hoping you can learn to swim.

FYI: I’ve had a couple of bad experiences with looking for a used mill in the size range of a cx601. I’m leaning towards getting a new Precision Mathews PM30mv which comes with an installed DRO (700us$ option)

I thought a mill with a DRO would be a great start. Then I’d learn the basic and maybe (?) upgrade to CNC. But I don’t have any plans to go CNC. Starting with a CNC mill seems like jumping into the deep end and hoping you can learn to swim.

FYI: I’ve had a couple of bad experiences with looking for a used mill in the size range of a cx601. I’m leaning towards getting a new Precision Mathews PM30mv which comes with an installed DRO (700us$ option)

DPittman

Ultra Member

Boy if you can swing a pm30mv with a dro installed think that would be a very sweet way to start!

I'm not into cnc, nor likely to ever be so my opinion on that may not be particularly relevant but.....I think you need to make some chips and projects for quite some time on a manual machine before being able to determine if cnc is right for you.

I'm not into cnc, nor likely to ever be so my opinion on that may not be particularly relevant but.....I think you need to make some chips and projects for quite some time on a manual machine before being able to determine if cnc is right for you.

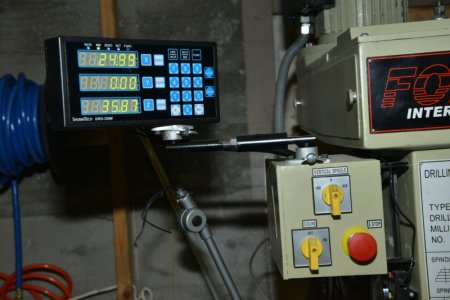

I have a Shumatech DRO-350 on my mill and it uses the caliper type scales with the strange protocol. I replaced the scale batteries with brass tube fabrications that looked like batteries but had capacitors. I have a spare un-assembled DRO-350. I intended to upgrade or add a DRO to the lathe so I bought and assembled a DRO-550 kit but other than testing haven't used it. A spare set of parts for that one too.

Although the web site is alive I don't think he sells them anymore. https://www.shumatech.com/web/products

Chinese products effectively killed that market.

I like having a separate DRO on my CNC conversion. It showed me that one of my DC servo motors was missing steps and didn't return to the starting position. As it turns out that motor had twice the inductance and winding resistance as the other 'identical' motor. I switched over to AC servos and haven't looked back.

My mill also came with power feed on the X so it was handy that way too. And with one of the battery touch probes, although I never connected it, I did use the find center feature that let me touch off between to edges of a circle or square and the DRO function would set the DRO zero to the middle. Very handy.

Although the web site is alive I don't think he sells them anymore. https://www.shumatech.com/web/products

Chinese products effectively killed that market.

I like having a separate DRO on my CNC conversion. It showed me that one of my DC servo motors was missing steps and didn't return to the starting position. As it turns out that motor had twice the inductance and winding resistance as the other 'identical' motor. I switched over to AC servos and haven't looked back.

My mill also came with power feed on the X so it was handy that way too. And with one of the battery touch probes, although I never connected it, I did use the find center feature that let me touch off between to edges of a circle or square and the DRO function would set the DRO zero to the middle. Very handy.

Attachments

The PF's prices are all over the place and most are the same unit, WEN DING. This is the one I bought and it is working well so far. I like the long handle for direction change rather than the rotary switch on some other models.

Some people have needed to make shims or bushings or mountings for non-BP machines (myself included) but that hasn't been a big issue for most. There are a few threads on installs here if you do a search.

Some people have needed to make shims or bushings or mountings for non-BP machines (myself included) but that hasn't been a big issue for most. There are a few threads on installs here if you do a search.

Former Member

Guest

My power feed lasted about a year and a half, mind you it got USED, I suspect that my use matched most for at least 10-15 years equivalent.

Over all they work well, but it was the final step that got me to go CNC.

Over all they work well, but it was the final step that got me to go CNC.

Mine was working fine when I took it off. It's in a box and will go with the mill if someone doesn't want the CNC. But that's a long time in the future.

DRO/CNC??? - I’m about to plunge into milling- I’ve never cut a chip on a mill before. I’m confused. Like SomeGuy - I’ll have to do some more learning/research/thinking.

I thought a mill with a DRO would be a great start. Then I’d learn the basic and maybe (?) upgrade to CNC. But I don’t have any plans to go CNC. Starting with a CNC mill seems like jumping into the deep end and hoping you can learn to swim.

FYI: I’ve had a couple of bad experiences with looking for a used mill in the size range of a cx601. I’m leaning towards getting a new Precision Mathews PM30mv which comes with an installed DRO (700us$ option)

I'm sorry @CWret , I missed your post somehow. I see you didn't get a response.

If you have the coin and the Precision Mathews meets your size needs, I'd almost always recommend buying new like that.

Personally, I'm too much of a penny pincher and almost always buy used and then repair/recondition. My approach usually wins and I end up $ ahead, but once in a while it doesn't and I end up in the hole. If I put a $ value on my time, I would almost always buy new.

The nice thing about new is that you are up and running right away. The nice thing about used is that you come to know your machine inside out.

Of course, I have my own view on the issue of plain vanilla vs DRO vs CNC. Others will no doubt disagree. I am a very firm believer in walking before you run. Some say you automatically learn to walk if you try to run first. Well...., that's their opinion not mine. I will always advocate a plain vanilla machine first. Learn to use it and learn to use it well. If you want cnc after that, either add it or trade your manual machine in and get a cnc machine to replace it. I don't have, and don't ever plan to have, cnc. It's not even on my list of wants. But that doesn't mean I look down my nose at CNC. I was part of the generation that brought CNC to industry. CAD/CAM was my whole life for a while. But fundamentally, I am a journey guy, not a destination guy. My joy is in making the part with my hands, not holding the finished part in my hands. I spent what seems like a lifetime as part of a CAD world. Now, I want to smell the roses and enjoy the journey of machining a block of metal into something beautiful.

I did add a 4-Axis DRO to my mill, and I am very glad that I did. But I don't always use it. I didn't even turn it on for the last two jobs I did. I may add Power Feed to my mill someday, but I'm in no rush even for that. I have no plans in my lifetime to add CNC.

Last edited:

Thanks for your insight @Susquatch - very much appreciated. If I end up with a mill without a DRO then I'll take your advise and get comfortable with it before looking for a DRO. By the way --- Ali is now offering a Ditron SINO 3 axis LCD @ 500.80 Ca$ with free shipping and that's without any haggling.

In a previous career I knew rock drilling inside out and I had no issues with buying a used (or abused) rock drill because new or used it would spend months in the shop to be torn apart/rebuilt and modified to suit our specialize purposes (see my Avatar).

I have no milling experience - so that is why I'm looking for a used mill in nearly new condition or I'll just bit the bullet & get new. Finding a used mill in excellent condition is a bit of a challenge. Milling for me is like sailing into unchartered waters - so I don't need added complications that a used mill might present. Also - I'm good at fixing things - but things I understand.

If I do go with the PM 30MV with a DRO, again I will take your advise and just leave the DRO turned off until I learn the basics of milling & the new machine.

Enjoy the hobby:

- I like to make things, it's great satisfaction but I don't want to waste time fixing stuff that should be making my goal easier.

- If I break it, then fixing it is usually fun.

Added plus for getting a PM mill with a DRO - Blondihacks has a good video explaining how the PM DRO works.

Also - I too have no intentions of ever going CNC.

Thanks again

Craig

In a previous career I knew rock drilling inside out and I had no issues with buying a used (or abused) rock drill because new or used it would spend months in the shop to be torn apart/rebuilt and modified to suit our specialize purposes (see my Avatar).

I have no milling experience - so that is why I'm looking for a used mill in nearly new condition or I'll just bit the bullet & get new. Finding a used mill in excellent condition is a bit of a challenge. Milling for me is like sailing into unchartered waters - so I don't need added complications that a used mill might present. Also - I'm good at fixing things - but things I understand.

If I do go with the PM 30MV with a DRO, again I will take your advise and just leave the DRO turned off until I learn the basics of milling & the new machine.

Enjoy the hobby:

- I like to make things, it's great satisfaction but I don't want to waste time fixing stuff that should be making my goal easier.

- If I break it, then fixing it is usually fun.

Added plus for getting a PM mill with a DRO - Blondihacks has a good video explaining how the PM DRO works.

Also - I too have no intentions of ever going CNC.

Thanks again

Craig

By the way --- Ali is now offering a Ditron SINO 3 axis LCD @ 500.80 Ca$ with free shipping

Assuming that is a sale price, which I doubt, then here is what you do.

You open a chat and ask what that price includes. Next you ask how much it will be for a 4 axis magnetic scale unit. If they are hot for a deal, they will say we will give you same price. At which time you ask about 1 micron. If they say same price, you ask about rpm.

If at any time they say too much more money, you say thank you but you cant afford that. If they don't come down you just stop haggling and wait a week, then chat them again the same way. And so forth and so on. Might be good to try at month end too when they need to make their quotas.

For big stuff like this they keep a log of your chats so they will know they need to give you a deal or you won't buy. It's really all about who blinks first and who has the biggest need.

SomeGuy

Hobbyist

Woohoo, chips!

The only suggestion I'd offer is to separate the vise from the swivel base to increase rigidity and get back a little Z height.

Craig

Yeah, guess that makes sense, unless I need the swivel for a cut, no point in having it there.

Thanks!