Hi all, glad i found this site. I'm an automotive tech with a large shop slowly filling up with machine tools. So far I have a Standard Modern 1660 10hp lathe, Emco V13 13x40 lathe, Kent 1054hs bridgeport clone that was once a cnc mill. These were all college machines and in very nice condition, but the mill had a broken leadscrew so they dumped it, even though it was an easy fix. I also have a Norton surface grinder, Doall bandsaw, and a few others. All my machines are 3 phase with VFDs. Always looking to trade knowledge and parts!

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New guy from Murillo (Thunder Bay) Ont

- Thread starter Darren

- Start date

Thanks everyone. I was looking for a Canadian specific place to hang out.

Here's a link to my shop build. Hope its ok to link to other forums:

https://www.garagejournal.com/forum/showthread.php?t=333623&page=4

It's been a long process but i'm getting some use out of the shop and having a lot of fun.

Here's a link to my shop build. Hope its ok to link to other forums:

https://www.garagejournal.com/forum/showthread.php?t=333623&page=4

It's been a long process but i'm getting some use out of the shop and having a lot of fun.

Thanks everyone. I was looking for a Canadian specific place to hang out.

Here's a link to my shop build. Hope its ok to link to other forums:

https://www.garagejournal.com/forum/showthread.php?t=333623&page=4

It's been a long process but i'm getting some use out of the shop and having a lot of fun.

Love the reuse of the shelving to make the cabinets.

This is my newest aquisition. The much sought after Emco V13. I won it on Govdeals and drove 48 hours round trip to get it home. After a good cleaning it turns out that it is pretty much in new condition.

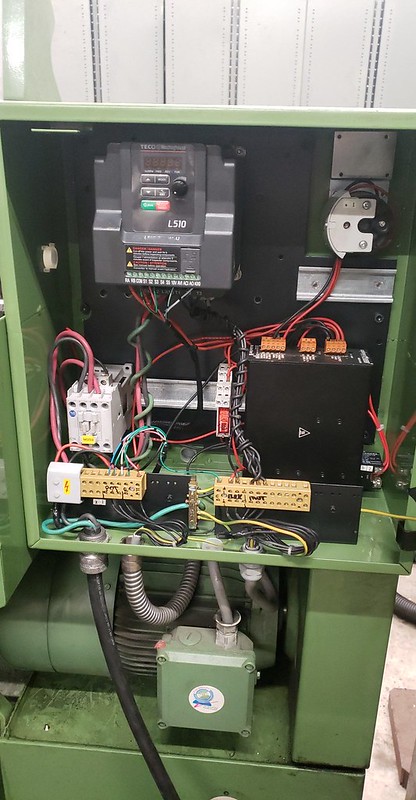

Ripped out the old guts and installed a VFD. This motor has a brake so i added a 6amp 24vdc power supply and a relay controlled by the vfd. It works very well.

This was my Emco V10p that i recently sold after I got the V13 home. I'm going to miss it. It was a great small lathe. I need to get a DRO on the V13 soon.

This is my mill. It was a CNC mill that the students at our local college somehow crashed with bad programming and they bound up the X axis ballnut on the screw, wrecked the scale and a few other bits. Unable to buy a direct replacement ballscrew, they put it up on Govdeals. I found a ballscrew on ebay and ordered it before i even bought the mill. Only problem was that it was a 32mm screw, where the factory screw was 25mm, so i had to do some mods. The screws are on the bench in the background.

A wee bit bigger.

Old screw on the top, i had to transfer the end to make it work.

I turned off the end of the new screw to 1/2" and drill and tapped the end for a 10-32 retainer screw

cut the end off the old screw and bored it to a sliding fit onto the 1/2" spigot

and glued it on with loctite retaining compound.

Like brand new

All back together.

I forgot about the Yoke mods. The larger ballnut required a larger bore in the yoke, which required a larger lathe. So i had to get my SM 1660 up and running.

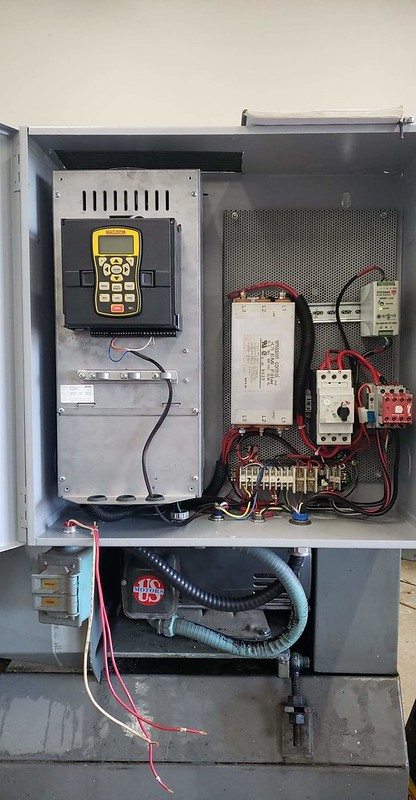

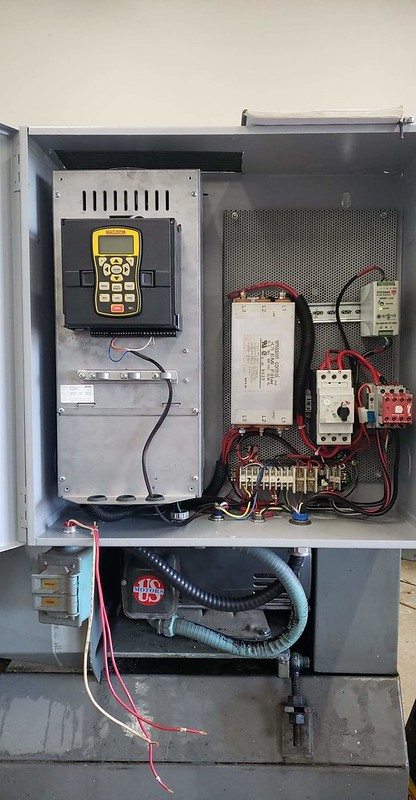

I had to swap out the 7.5hp 575v motor for a 10hp 240v motor. I found it on Facebook marketplace, same frame size. I then added a 25hp VFD and all the required bits

https://live.staticflickr.com/video...GEzZmE5MjRiZjIyZjBhMjkzM2M0OGExYmMiLCJ2IjoxfQ

typical work on the big lathe

I had to swap out the 7.5hp 575v motor for a 10hp 240v motor. I found it on Facebook marketplace, same frame size. I then added a 25hp VFD and all the required bits

https://live.staticflickr.com/video...GEzZmE5MjRiZjIyZjBhMjkzM2M0OGExYmMiLCJ2IjoxfQ

typical work on the big lathe

Last edited: