A friend sent me this link. Amazing entry level printer. Not for me since my next one will be totally enclosed but still impressive for the price.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New 3D printer

- Thread starter jcdammeyer

- Start date

I don't normally like to wait forever for things to mature. In fact, most of the time I am an early adopter. My bride and I used txt on a numeric keyboard on the early cell phones. It was called T9 back then. We both loved it cuz we could chat without anyone having any idea what we were doing.

But in this case, I've been waiting for the technology to mature. Some say it is ready now, but I'm confess I'm hesitant.

But in this case, I've been waiting for the technology to mature. Some say it is ready now, but I'm confess I'm hesitant.

In the past 12 months, there has been significant progress in 3DP. The main aspects make for a plug-and-play experience, and significantly faster printing, with a wider range of materials for all of the higher end printers.

I don't think we are all there yet, but at least the current ones won't be boat anchors in the foreseeable.

If I didn't have 4,000 projects on the go, I'd give one of the current offerings a shot.

I don't think we are all there yet, but at least the current ones won't be boat anchors in the foreseeable.

If I didn't have 4,000 projects on the go, I'd give one of the current offerings a shot.

Alright. You got me! I only have 42 projects on the go. You win!In the past 12 months, there has been significant progress in 3DP. The main aspects make for a plug-and-play experience, and significantly faster printing, with a wider range of materials for all of the higher end printers.

I don't think we are all there yet, but at least the current ones won't be boat anchors in the foreseeable.

If I didn't have 4,000 projects on the go, I'd give one of the current offerings a shot.

I could have sworn the majority of your projects had subprojects..... @Dabbler may have you beat at 4000, but I'll bet his lead isn't as big as you think!Alright. You got me! I only have 42 projects on the go. You win!

lucsimoneau

Well-Known Member

lucsimoneau

Well-Known Member

Not really plug and play but easy enough to get into 3DP with a mature product.

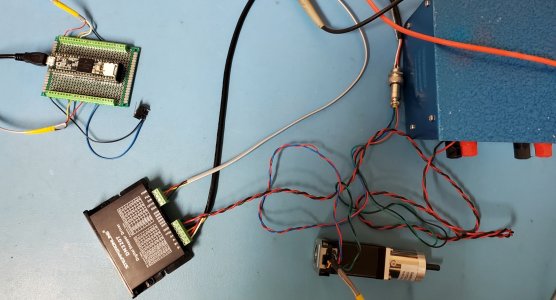

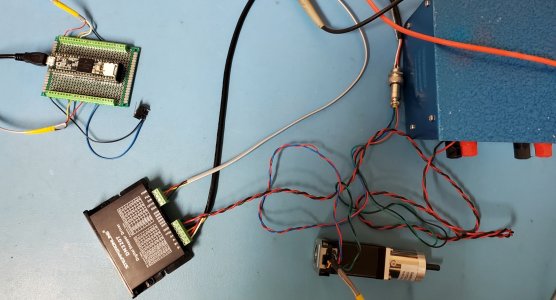

I need to 3D print a box to hold the Teensy 3.5 plugged into the proto board. Tonight, since my cables arrived from China I wired up the stepper motor for Joint 4 and the encoder and then got it to move.

I know. Simple. But I'm trying to get a handle on how the software works even if I don't have the metal parts for the robot arm yet.

This is the smallest motor of the lot. The driver is max 30V so I used a 24V/5V supply I built back in 1992 in The Netherlands. The Teensy 3.5 is powered by USB and the 5V from that USB powers the encoder. I was able to make the robot software turn the motor. Good times.

I know. Simple. But I'm trying to get a handle on how the software works even if I don't have the metal parts for the robot arm yet.

This is the smallest motor of the lot. The driver is max 30V so I used a 24V/5V supply I built back in 1992 in The Netherlands. The Teensy 3.5 is powered by USB and the 5V from that USB powers the encoder. I was able to make the robot software turn the motor. Good times.

You have a project book? Dang.. I just have a project whiteboard. And an overloaded brain so maybe that's the same?I got my project book back. Darn! Now I have to start doing things again.

140mower

Don

Aye, it's one of the things that I miss the most. 🙄-At least you have a brain! I lost my mind some time ago!