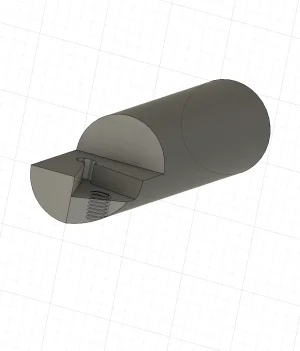

Looking for a . . . 2” Dia x 45 deg. I have 1/2” and 5/8” R8 collets, As well as 10 and 16mm sizes.

I have went looked thru the Chinese Products on Aliexpress & Amazon, but, they tend to leave the shank dimensions out of the description.

Any experiences or recommendations to share ?

I have went looked thru the Chinese Products on Aliexpress & Amazon, but, they tend to leave the shank dimensions out of the description.

Any experiences or recommendations to share ?