-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My welding challenge

- Thread starter Don Sipes

- Start date

Not sure what I’m talking about here or what the process is called, maybe an experienced welder could help, please chime in- but I recall a ‘weld.com’ or maybe a ‘tipandtricks’ youtube when both sides of the piece are exposed (protected) by the same shielding gas. In your case: the inside of the exhaust pipe would be filled with the same shielding gas as the flow from your torch (MIG or TIG).

I agree with a smile TIG is going to be tricky and burn holes right through - I'm not sure @Tom O how you did that. You must be a good welder.

So I have two Ideas for you.

#1 How about spot welding? With a thin backing plate to join the parts together?

#2 I watched a welder working on exhaust pipes (youtube) using MIG and a timer to shut off after 0.5s. The welding machine had this function. I don't have that on my welder but I successfully did it on exhaust pipe with just brief pulses on the trigger. Pulse, move a bit, pulse, move a bit. Slow and steady. Maybe try that on test material and see if you get good welds, adjust to suit. ???

One other point - it's an exhaust not an intake - if it sugars is that actually a problem? If anything falls off then it just rolls out? no harm? or are there other issues?

So I have two Ideas for you.

#1 How about spot welding? With a thin backing plate to join the parts together?

#2 I watched a welder working on exhaust pipes (youtube) using MIG and a timer to shut off after 0.5s. The welding machine had this function. I don't have that on my welder but I successfully did it on exhaust pipe with just brief pulses on the trigger. Pulse, move a bit, pulse, move a bit. Slow and steady. Maybe try that on test material and see if you get good welds, adjust to suit. ???

One other point - it's an exhaust not an intake - if it sugars is that actually a problem? If anything falls off then it just rolls out? no harm? or are there other issues?

Last edited:

Make sure your fit up is perfect any gap on the thin of material is gonna cause you world of nothing but problems

Your not gonna much filler 1/16 er70 would be fine mig wire would be fine too I would leen towards .045 if going that root as wire isn't stable and you'll miss your puddle that and you'll be feeding 6 inches of wire to go 1 inch lol.

You could try Tig brazing it with silicone bronze but that's another learning curve, does look beautiful when done correctly.

You could even just mig weld it with .023 mig hardwire then use orbital air sander to smooth welds out. If you do million tacks can kinda make it look like Tig and would be easy to control distortion.

I would recommend Tig 30amps or less machine dependant with 3/32 tungsten 2% throated or 1.5% ceriated tungsten and atleast #12 gas cup and gas lenses. If you have access to foot petal or pulse I would recommend using them lol.

If not your gonna basically find setting that doesn't burn threw and start the arc with high freq if machine has it.

If not use your filler rod to start the arc by hovering your tungsten over your work piece and then tap the filler between tungsten and work piece way easier when you get hang of it then scratch start and almost no chance of tungsten inclusions.

Once your arc is started dip your filler to make small puddle and try and joint the pieces together at same time then just drag the arc inch or so and stop. You shouldn't need to add anymore filler besides when you join the two pieces. then just hop around work piece evenly ish till joint is welded out.

If done correctly your weld will be flush and fully fused on inside. If you weld starts to get too concaved turn down amps or move faster. If machine will not go down low enough use bigger tungsten and try again.

This method should be achievable with even a 80$ amazon Tig machine or any DC welding machine no bells and whistles just practice. O ye and use a welding shield with auto darkening that is sensitive enough for low amp welding. If not just used fixed and get used to flipping it down and not stray arcing everything.

I don't have much pulse experience or I would give some advice on that. and when I use foot petal it's generally pushed down to the floor. I prefer thumb switch to use as on off switch.

I wasn't blessed as a field welder to have nice things just diesel generators or miller 180 stls or miller 350 xmts inverters basically anything that could weld was used lol. Shop guys get the nice stuff with all the settings and stuff.

Edit:

If somthing doesn't make sense ask I'll try to clarify. Trying to get stuff from brain to paper doesn't always work and welding is part muscle memory/feel.

With thin wall stuff reaction time is a bonus

Your not gonna much filler 1/16 er70 would be fine mig wire would be fine too I would leen towards .045 if going that root as wire isn't stable and you'll miss your puddle that and you'll be feeding 6 inches of wire to go 1 inch lol.

You could try Tig brazing it with silicone bronze but that's another learning curve, does look beautiful when done correctly.

You could even just mig weld it with .023 mig hardwire then use orbital air sander to smooth welds out. If you do million tacks can kinda make it look like Tig and would be easy to control distortion.

I would recommend Tig 30amps or less machine dependant with 3/32 tungsten 2% throated or 1.5% ceriated tungsten and atleast #12 gas cup and gas lenses. If you have access to foot petal or pulse I would recommend using them lol.

If not your gonna basically find setting that doesn't burn threw and start the arc with high freq if machine has it.

If not use your filler rod to start the arc by hovering your tungsten over your work piece and then tap the filler between tungsten and work piece way easier when you get hang of it then scratch start and almost no chance of tungsten inclusions.

Once your arc is started dip your filler to make small puddle and try and joint the pieces together at same time then just drag the arc inch or so and stop. You shouldn't need to add anymore filler besides when you join the two pieces. then just hop around work piece evenly ish till joint is welded out.

If done correctly your weld will be flush and fully fused on inside. If you weld starts to get too concaved turn down amps or move faster. If machine will not go down low enough use bigger tungsten and try again.

This method should be achievable with even a 80$ amazon Tig machine or any DC welding machine no bells and whistles just practice. O ye and use a welding shield with auto darkening that is sensitive enough for low amp welding. If not just used fixed and get used to flipping it down and not stray arcing everything.

I don't have much pulse experience or I would give some advice on that. and when I use foot petal it's generally pushed down to the floor. I prefer thumb switch to use as on off switch.

I wasn't blessed as a field welder to have nice things just diesel generators or miller 180 stls or miller 350 xmts inverters basically anything that could weld was used lol. Shop guys get the nice stuff with all the settings and stuff.

Edit:

If somthing doesn't make sense ask I'll try to clarify. Trying to get stuff from brain to paper doesn't always work and welding is part muscle memory/feel.

With thin wall stuff reaction time is a bonus

Last edited:

Called back-shielding, or back-purging. It was suggested earlier in the thread. Won't call it a waste of time and money, but for a mild steel exhaust system, pretty close to that! If the fit is good, and the weld is progressing nicely, there will be very little internal protrusion of the bead.Not sure what I’m talking about here or what the process is called, maybe an experienced welder could help, please chime in- but I recall a ‘weld.com’ or maybe a ‘tipandtricks’ youtube when both sides of the piece are exposed (protected) by the same shielding gas. In your case: the inside of the exhaust pipe would be filled with the same shielding gas as the flow from your torch (MIG or TIG).

Different gig if the pipe pieces are Stainless, or Titanium. Either will react badly to the exposure of oxygen from the air, to the heat of the weld pool. Some of the outfits that weld Titanium, go to the trouble of welding in a closed box, very similar to a sand blaster, with a totally Argon environment inside.

I disagree with @Janger and @a smile that burning holes is going to be a problem. Applying too many amps, or too much heat, will burn holes. Adjust accordingly! Start low, on practice pieces, work your way up in amperage, until you are moving at a relaxed, comfortable speed. Same with oxy-acet welding. Except that in O/A welding, you have a slightly different reflex to learn, to control the heat that goes in to the work, where you have to learn to twitch the torch flame back away from the weld, to spread that heat out, rather than dialing down the amperage. You also have a fairly "blowy" flame to deal with, which may add to the issue.

Amps = Heat, in TIG, a larger torch tip size = Heat, in O/A welding. In the latter you can cheat a bit, with lower pressures to the torch, but that usually results in more pops and farts too! I have seen O/A torches that used hypodermic needles, as torch tips (some jewellery supply places sell a set), though never attempted to weld with one, and a friend of mine, who was a former Northern Alberta Institute of Technology (NAIT) Instructor, demoed his rig that he made up to fusion weld some VERY small parts, under a microscope, that used, essentially, the finest needles he could get, and a regulator system that used baby food jars full of water, where he counted the bubbles per minute, or the seconds between them, as a way to set his gas flows! Which is to say, if you are blowing holes, you are using too much heat. Period!

But both processes rely on the exact same hand/eye/rhythm coordination. Make a puddle, feed the filler (if needed), move, repeat. Better to take a second for a puddle to form (as you are setting up), than to blow a chunk out of the part, and have to learn how to deal with that (and that CAN be dealt with!).

Speaking of dealing with blowouts... Copper is your friend! The steel weld material, will not stick to copper or copper alloys. Some sections of copper pipe, cut and flattened, and formed to fit inside the blown out area, can be a life-saver! Especially if you have your machine dialed all the way down, and you are trying to build sideways off the edges of the hole you just blew out on the part! If you can form the copper sheet to the inside of the part, you have a tool that will save you a LOT of time in recovery, and prevent leaving a huge scab on the inside of the pipe.

We used a lot of brass bars and blocks, to back up inside corners of quick and dirty fusion welded outside corners of steel drip trays and pans, boxes, etc., when we were making them. Dead easy to bend the box up with a tight inside radius, and whip down the seam really fast with a TIG torch to fuse the seam.

Keep solidly in mind, that it is not that you will not ever screw up a part. It is how you learn from, and recover from that screw-up, that will be how you develop your skills!

Agree with @justin1, above. Get a decently sensitive helmet! I don't agree with his pedal method, really, but if it works for him and his, it works. I prefer to be able to tap the pedal and either start at a very low amperage and work up, or at least, if I want to get the part hot in short time, stomp it down, and back off immediately to a comfortable heat level. As I said before, by being able to manipulate the heat live, you have the options of welding in the third dimension, have seen and done a LOT of pretty neat 'art' projects so done, as well as some very creative ways of bridging very wide gaps, and filling in between free-standing beads.

The more you practice and, really, Play, the more options you will find, when you are not making parts to some engineer's very strictly laid out welding process that you must follow.

Welding, more than many skills, requires a pretty solid grasp of being able to recognize what is going on, and reacting to it in real time. Dead nuts easy, when they spell it all out in an engineered (hopefully competently) Process sheet, but when you do not have fixed settings and fillers, and gaps spec'd out for you in advance, you pretty much have to fall back on experience. It's less of a disaster in the making, if you start at the bottom of the settings, and work up, than if you start at the top, and work down until you are happy with the results!

Last edited:

Chris Cramer

Super User

That is a good technique for repairing holes on thin material. The metal added to the bead adds more heat resistance every time, and the bead is something to point the arc towards to withstand the heat. Adding metal to the bead works to cool the weld. If you have a foot pedal you can also use that to control the heat. I like tig welding the most because of how much control it gives you over the heat and feed rate.Pulse, move a bit, pulse, move a bit. Slow and steady.

YES it does. But I have never really used it.Does your tig welder have pulse capabilities? I really liked using pulse on my bicycle tubing, although that was ~0.035" wall thickness.

I'd second using mig wire as filler. Rule of thumb is for the filler to be no thicker than what you are welding, but I don't know if 0.020" mig wire is readily available?

For the moment I have been trying OA. I get SOME good results, but getting the same heat each time I start the torch is my current challenge. I'm using a zero TIp and turning up the A to get just out of the smoke zone then adding O. The just out of smoke zone is not always consistent. I see why your friend counted bubbles in the baby food jars. I'll keep working on it.Called back-shielding, or back-purging. It was suggested earlier in the thread. Won't call it a waste of time and money, but for a mild steel exhaust system, pretty close to that! If the fit is good, and the weld is progressing nicely, there will be very little internal protrusion of the bead.

Different gig if the pipe pieces are Stainless, or Titanium. Either will react badly to the exposure of oxygen from the air, to the heat of the weld pool. Some of the outfits that weld Titanium, go to the trouble of welding in a closed box, very similar to a sand blaster, with a totally Argon environment inside.

I disagree with @Janger and @a smile that burning holes is going to be a problem. Applying too many amps, or too much heat, will burn holes. Adjust accordingly! Start low, on practice pieces, work your way up in amperage, until you are moving at a relaxed, comfortable speed. Same with oxy-acet welding. Except that in O/A welding, you have a slightly different reflex to learn, to control the heat that goes in to the work, where you have to learn to twitch the torch flame back away from the weld, to spread that heat out, rather than dialing down the amperage. You also have a fairly "blowy" flame to deal with, which may add to the issue.

Amps = Heat, in TIG, a larger torch tip size = Heat, in O/A welding. In the latter you can cheat a bit, with lower pressures to the torch, but that usually results in more pops and farts too! I have seen O/A torches that used hypodermic needles, as torch tips (some jewellery supply places sell a set), though never attempted to weld with one, and a friend of mine, who was a former Northern Alberta Institute of Technology (NAIT) Instructor, demoed his rig that he made up to fusion weld some VERY small parts, under a microscope, that used, essentially, the finest needles he could get, and a regulator system that used baby food jars full of water, where he counted the bubbles per minute, or the seconds between them, as a way to set his gas flows! Which is to say, if you are blowing holes, you are using too much heat. Period!

But both processes rely on the exact same hand/eye/rhythm coordination. Make a puddle, feed the filler (if needed), move, repeat. Better to take a second for a puddle to form (as you are setting up), than to blow a chunk out of the part, and have to learn how to deal with that (and that CAN be dealt with!).

Speaking of dealing with blowouts... Copper is your friend! The steel weld material, will not stick to copper or copper alloys. Some sections of copper pipe, cut and flattened, and formed to fit inside the blown out area, can be a life-saver! Especially if you have your machine dialed all the way down, and you are trying to build sideways off the edges of the hole you just blew out on the part! If you can form the copper sheet to the inside of the part, you have a tool that will save you a LOT of time in recovery, and prevent leaving a huge scab on the inside of the pipe.

We used a lot of brass bars and blocks, to back up inside corners of quick and dirty fusion welded outside corners of steel drip trays and pans, boxes, etc., when we were making them. Dead easy to bend the box up with a tight inside radius, and whip down the seam really fast with a TIG torch to fuse the seam.

Keep solidly in mind, that it is not that you will not ever screw up a part. It is how you learn from, and recover from that screw-up, that will be how you develop your skills!

Agree with @justin1, above. Get a decently sensitive helmet! I don't agree with his pedal method, really, but if it works for him and his, it works. I prefer to be able to tap the pedal and either start at a very low amperage and work up, or at least, if I want to get the part hot in short time, stomp it down, and back off immediately to a comfortable heat level. As I said before, by being able to manipulate the heat live, you have the options of welding in the third dimension, have seen and done a LOT of pretty neat 'art' projects so done, as well as some very creative ways of bridging very wide gaps, and filling in between free-standing beads.

The more you practice and, really, Play, the more options you will find, when you are not making parts to some engineer's very strictly laid out welding process that you must follow.

Welding, more than many skills, requires a pretty solid grasp of being able to recognize what is going on, and reacting to it in real time. Dead nuts easy, when they spell it all out in an engineered (hopefully competently) Process sheet, but when you do not have fixed settings and fillers, and gaps spec'd out for you in advance, you pretty much have to fall back on experience. It's less of a disaster in the making, if you start at the bottom of the settings, and work up, than if you start at the top, and work down until you are happy with the results!

Proxule

Ultra Member

PULSE - yes!Does your tig welder have pulse capabilities?

For the moment I have been trying OA. I get SOME good results, but getting the same heat each time I start the torch is my current challenge. I'm using a zero TIp and turning up the A to get just out of the smoke zone then adding O. The just out of smoke zone is not always consistent. I see why your friend counted bubbles in the baby food jars. I'll keep working on it.

set you heat with the acetylene regulator, crank the torch valve full open, lite it and adjust the regulator to the heat you want. This way all you need to do is crank open the torch valve full, lite, adjust to neutral flame and you will have the same heat every time, you can do the same thing with the oxygen regulator so that you are adjusting to the same heat neutral flame every time as well.

This how i was taught to oxy weld, and have a consistent heat

Thanks - nice tip. Gonna give it a try.set you heat with the acetylene regulator, crank the torch valve full open, lite it and adjust the regulator to the heat you want.

Xyphota

Ultra Member

set you heat with the acetylene regulator, crank the torch valve full open, lite it and adjust the regulator to the heat you want. This way all you need to do is crank open the torch valve full, lite, adjust to neutral flame and you will have the same heat every time, you can do the same thing with the oxygen regulator so that you are adjusting to the same heat neutral flame every time as well.

Do you know of any reputable and economic oxy acetylene regulators with very low pressure ranges? For bicycle brazing I don't think I'll ever need more than 5-6 psi. I set my oxygen regulator for bicycle brazing by just dialing in the valve until I can just see the needle pop off zero lol.

Do you know of any reputable and economic oxy acetylene regulators with very low pressure ranges? For bicycle brazing I don't think I'll ever need more than 5-6 psi. I set my oxygen regulator for bicycle brazing by just dialing in the valve until I can just see the needle pop off zero lol.

Trust me when I say I have zero experience. I do use OA though so maybe zero isn't the right term. Low might be better.

I think the high pressure gauge (tank pressure) is the only one that needs to be special. The low pressure gauge can really be anything specific to your needs as long as it's compatable with the gas you use.

If it were me, and assuming that your regulator can be set low enough, I'd just go buy a gauge that has the right pressure range for your needs and swap it out for the one you have in there now.

It's either that or buy another regulator set and modify it.

Chris Cramer

Super User

The regulator on the acetylene cylinder is set to 8 and the oxygen is set to 20. The knobs on the torch are what is used to control the flame. You can get very little heat by slightly twisting the acetylene knob and adjust it to a small sized flame and using the oxygen to bring it to a neutral flame.

Do you know of any reputable and economic oxy acetylene regulators with very low pressure ranges? For bicycle brazing I don't think I'll ever need more than 5-6 psi. I set my oxygen regulator for bicycle brazing by just dialing in the valve until I can just see the needle pop off zero lol.

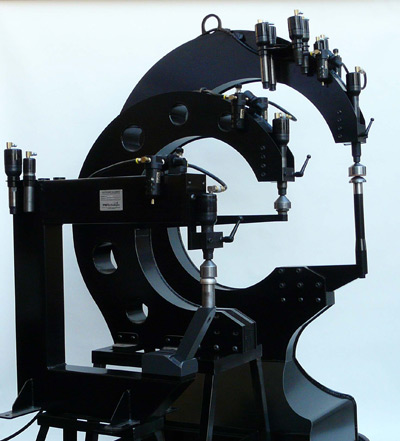

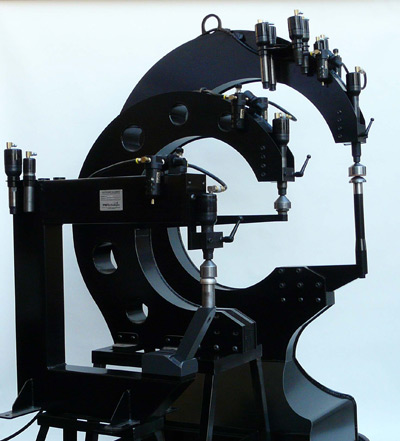

I'm not a hot stuff practitioner yet but I have heard a lot of good things about this MECO torch for specialty applications, using conventional OA regs AFAIK. It apparently has a wide(er?) range of tips & broader fuel valve control. Supposedly favored by guys doing everything between chromoly aircraft tubing structures down to basically jewelry scale stuff.

OTOH, Paul Brodie seems to be using a conventional torch for his bike stuff. He also has some tricks like adding flux to gas? Not sure if this is the vid, he has done a few on his channel.

I'm not a hot stuff practitioner yet but I have heard a lot of good things about this MECO torch for specialty applications, using conventional OA regs AFAIK. It apparently has a wide(er?) range of tips & broader fuel valve control. Supposedly favored by guys doing everything between chromoly aircraft tubing structures down to basically jewelry scale stuff.

Meco Torch and Accessories by TM Technologies

TM Technologies: Tools, Sheet Metal Shaping Machines, Gas Welding Supplies, Articles & lWorkshops for Better Metalworking

www.tinmantech.com

OTOH, Paul Brodie seems to be using a conventional torch for his bike stuff. He also has some tricks like adding flux to gas? Not sure if this is the vid, he has done a few on his channel.

Do you know of any reputable and economic oxy acetylene regulators with very low pressure ranges? For bicycle brazing I don't think I'll ever need more than 5-6 psi. I set my oxygen regulator for bicycle brazing by just dialing in the valve until I can just see the needle pop off zero lol.

like @Susquatch mentioned you could just change the low pressure gauge on the regulator to one that reads in the range you use

its been a while, but iirc the actual pressure (psi) used to create a neutral flame with o2 and act are equal (as is the volume of gas being 1:1), so a low pressure gauge that reads the same range as your act regulator low pressure gauge would do the trick, for brazing and welding at least, it would be no good for oxy/act torch cutting

it is pretty easy to be consistent setting the neutral flame, so im unsure that it is worth the trouble. The big heat range adjustment is more with the act pressure used, and you already have a gauge that is acceptable 😉

Xyphota

Ultra Member

I'm not a hot stuff practitioner yet but I have heard a lot of good things about this MECO torch for specialty applications, using conventional OA regs AFAIK. It apparently has a wide(er?) range of tips & broader fuel valve control. Supposedly favored by guys doing everything between chromoly aircraft tubing structures down to basically jewelry scale stuff.

OTOH, Paul Brodie seems to be using a conventional torch for his bike stuff. He also has some tricks like adding flux to gas? Not sure if this is the vid, he has done a few on his channel.

Yeah I've read on some bicycle framebuilder forums that people like that torch. I am using a 'little smith' torch clone, as I got it for pretty cheap at KMS tools. I think Mr. Brodie is using a uniweld 71 torch or something of similar size. He is using an inline gas fluxer. I have a gas fluxer but I haven't used it yet lol.

not sure if this was feedback for me or ducdon, but I think having the highest resolution gauge available for whatever the brazing/welding application would (atleast for the acetylene) make learning a bit easier. Fully opening the acetylene valve at the torch and then setting the flow rate with the regulator to a specific number I think would make it much easier to atleast keep your flame size consistent between torch sessions, no? Is there a safety reason this should not be done?it is pretty easy to be consistent setting the neutral flame, so im unsure that it is worth the trouble. The big heat range adjustment is more with the act pressure used, and you already have a gauge that is acceptable 😉

I agree you don't really need the precision gauge on the oxygen as you are just looking for the neutral flame either way.

Xyphota

Ultra Member

If it were me, and assuming that your regulator can be set low enough, I'd just go buy a gauge that has the right pressure range for your needs and swap it out for the one you have in there now.

It's either that or buy another regulator set and modify it.

That seems obvious to me now that you point it out! that hadn't even occurred to me. I'll look into, thanks.

Fully opening the acetylene valve at the torch and then setting the flow rate with the regulator to a specific number I think would make it much easier to atleast keep your flame size consistent between torch sessions, no? Is there a safety reason this should not be done?

yes, this is the procedure i outlined for the acetylene in my previous post (#31), crank open the acetylene valve on the torch and set your pressure on the regulator. there is no need to change that gauge, 0-15 is plenty of resolution, if your running below say 4psi of acetylene you should drop down tip sizes and start again. you only realistically have between say 4-10 psi of adjustment (in 1 psi increments) per size of tip, below say 4 ish, smaller tip, above 10 bigger tip.

the big heat (BTU) changes are tip size, then the fine tuning is done with acetylene pressure, every tip is capable of a range of heat (BTU output), so you have 2 variables to consider, tip size and acetylene pressure, with the combo of the two you should be able to get a controllable level of heat input

you can always buy the smallest size welding tip available, and drill it out as needed