RobinHood

Ultra Member

I think that would be the ideal world. But unless you grind the contact face parallel to the base of the jaw, this is not going to happen for parts which are larger in OD than the diameter at which the grinding took place.It seems like it should always be a larger radius than any part you might chuck,

This is what happens when chucking a part larger than the grind diameter: two lines of contact per jaw. I have not found any problem centering parts of larger diameter. One has to “feel” for it seating by slightly turning the part in the chuck as you start snuggling up the jaws.Too small and you'd be chucking on 2 points per jaw

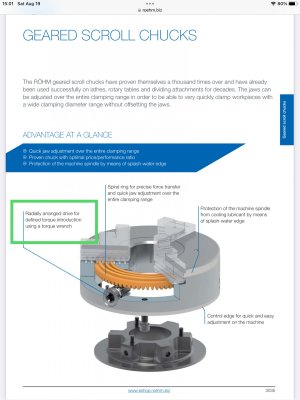

My Röhm 3J has a super accurate scroll which is very snug inside the body with an absolute minimum of radial play. Thus the chuck is accurate at all diameters.