-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mikes shop activities

- Thread starter Mike R

- Start date

The mfg defect is limited to the backplate that is a separate part from the chuck itself. Truly worst case scenario is I machine the backplate myself - redo the 6 holes clocked 60° from where they are now, but I'd rather try and make Vevor do some work. If it had been marketed as a factory second quality item with "known minor defects" and I'd bit on that I'd have no grief, but I need to have a little backbone and not accept defective items.Sounds like the 6 Jaw is a decent chuck albeit the shortcomings of manufacturing finishing and the socket head screws threaded too deep.

I was wondering if you can screw in a short grub screw of the same size / pitch and have it bottom out and then insert the pin locking screw?

On the one hand they claim:

30 day Free returns (detail is for "approved reasons")

and on the other hand - reading their terms of service: "We do not warrant that the quality of any products, services, information, or other material purchased or obtained by you will meet your expectations or that any errors in the service will be corrected." !!!!!!!

The Amazon price (for exactly the same item from Vevor) - is $311 instead of $269, but I guess thats the cost of having Amazon handle customer issues for you (ships and sold by Amazon) Amazon page: Vevor 6 jaw 6 inch chuck

I find that the Vevor credit washes out with Amazon free shipping.

Vevor is pretty fast.

But getting quality from Vevor is hopeless. Usually, they refund me some money to make me happy.

Nothing about your story scares me. It's typical Vevor.

Question - is the backplate removable and could it be modified to set-true type operation?

While you have it apart, could you take some photos of the backplate interface?

Vevor is pretty fast.

But getting quality from Vevor is hopeless. Usually, they refund me some money to make me happy.

Nothing about your story scares me. It's typical Vevor.

Question - is the backplate removable and could it be modified to set-true type operation?

While you have it apart, could you take some photos of the backplate interface?

@Mike R - I'm still interested in this. I'd love a small 6 jaw chuck. But my lathe is D1-5. Hence my backplate related questions.

If I were making some changes for the lock screws, I'd either

1. Machine an appropriate tube a few inches long and then part off small lengths to use as spacer sleeves, or

2. Buy screws with longer heads.

I don't mind cleaning up a Vevor chuck, and adapting a 6 stud D1-5 backplate isn't a huge challenge either - provided that there are no show stoppers. Hence my earlier questions above:

1. Is the backplate removable and could it be modified to set-true type operation?

2. While you have it apart (assuming you do), could you take some photos of the backplate interface? Is it a tapered register, a simple shouldered register, or just a flat bolted interface?

If I were making some changes for the lock screws, I'd either

1. Machine an appropriate tube a few inches long and then part off small lengths to use as spacer sleeves, or

2. Buy screws with longer heads.

I don't mind cleaning up a Vevor chuck, and adapting a 6 stud D1-5 backplate isn't a huge challenge either - provided that there are no show stoppers. Hence my earlier questions above:

1. Is the backplate removable and could it be modified to set-true type operation?

2. While you have it apart (assuming you do), could you take some photos of the backplate interface? Is it a tapered register, a simple shouldered register, or just a flat bolted interface?

I’ll try and take a few more pictures either tonight or tomorrow. The backplate is removable but I’m unsure as of now if it’s adaptable to be set-true, or if it’s tapered or straight. It bolts on with 3 SHCS and I’ll grab the size of those. Still no reply from Vevor

Sorry about the mixed units, kinda realized that everything is metric and that would have resulted in the nominal numbers making sense. Like the 130mm diameter of the registration boss on the back plate and chuck. Its about 3.5mm (.140") high. The whole backplate is about 0.99" thick at its max, and about .788" on its biggest diameter.

The boss has a square edge as best as I can tell. I don't think that its an easy mod to set-tru type. The distance between the back of the chuck and the pinion is ~10mm and the machined recess is about 12.5mm, if you toss the plastic backplate and instead figure out a way to seal up to a new modified backplate. You might be able to machine the backplate to sit in deeper to give a shoulder for screws to push on, but in my opinion is going to be right on the edge even with small screws, unless you get fancy with angled holes, etc.

FYI - Vevor responded - they don't see an issue, so I'm on my own. I think I will redrill and tap the stud holes, I'm just not comfortable with the thread fit either. Will be a nice little project to refamiliarize myself with the shop after the summer away from it.

The boss has a square edge as best as I can tell. I don't think that its an easy mod to set-tru type. The distance between the back of the chuck and the pinion is ~10mm and the machined recess is about 12.5mm, if you toss the plastic backplate and instead figure out a way to seal up to a new modified backplate. You might be able to machine the backplate to sit in deeper to give a shoulder for screws to push on, but in my opinion is going to be right on the edge even with small screws, unless you get fancy with angled holes, etc.

FYI - Vevor responded - they don't see an issue, so I'm on my own. I think I will redrill and tap the stud holes, I'm just not comfortable with the thread fit either. Will be a nice little project to refamiliarize myself with the shop after the summer away from it.

Sorry about the mixed units, kinda realized that everything is metric and that would have resulted in the nominal numbers making sense. Like the 130mm diameter of the registration boss on the back plate and chuck. Its about 3.5mm (.140") high. The whole backplate is about 0.99" thick at its max, and about .788" on its biggest diameter. The boss has a square edge as best as I can tell.

Thanks very much for that Mike. You have probably given me the courage I needed to order one.

I'll need to pitch (or sell) the backplate that comes with it and replace it with a D1-5.

I don't think that its an easy mod to set-tru type. The distance between the back of the chuck and the pinion is ~10mm and the machined recess is about 12.5mm, if you toss the plastic backplate and instead figure out a way to seal up to a new modified backplate. You might be able to machine the backplate to sit in deeper to give a shoulder for screws to push on, but in my opinion is going to be right on the edge even with small screws, unless you get fancy with angled holes, etc.

I'll get an extra thick backplate so I can work out a way to make it set tru. I think that cams might be better than the normal jack screws because the thickness of the shoulder register issue goes away. Worse comes to worse, I won't be set true. Big deal. I have a collet chuck that I use more often anyway.

FYI - Vevor responded - they don't see an issue, so I'm on my own. I think I will redrill and tap the stud holes, I'm just not comfortable with the thread fit either. Will be a nice little project to refamiliarize myself with the shop after the summer away from it.

I'm not sure what you mean here. Unless I misunderstood the problem, just make screw head sleeves or get screws with longer heads as per my earlier post.

if you toss the plastic backplate

What? The backplate is plastic??? I've never seen such a thing! I think that I'd toss such a thing even it was not a problem!!!

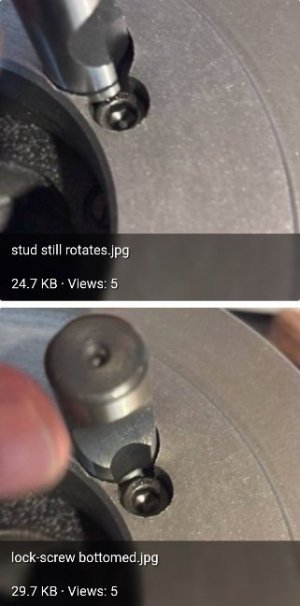

Another question. What are these screws for? I've never seen screws there. I've highlighted them for you below. Shouldn't they be on the other side of the plate? Did you put them in backwards?

You can see the plastic backplate / cover in the 2nd (removed and lying above) and 3rd pic (installed) in post #30 of this thread - the one where I start talking about this chuck.

I didn't fully explain my misgivings with the backplate. The locking screws were the first thing I noticed not being right. Later on I became uncomfortable with the fit of the threaded cam studs in the back plate - very loose fit for a relatively fine thread, plus with the clearance hole being drilled and extra few millimeters, and the ends of the threaded studs being chamfered means that there are only maybe 8 turns engaged with a very loose fit. I know only 3-4 threads engaged are really doing all the work, but the loose fit just started eating away at me.

The things you circled are the ends of the camlock studs from the chuck side of the backplate, with the little locking screw holes beside them.

I didn't fully explain my misgivings with the backplate. The locking screws were the first thing I noticed not being right. Later on I became uncomfortable with the fit of the threaded cam studs in the back plate - very loose fit for a relatively fine thread, plus with the clearance hole being drilled and extra few millimeters, and the ends of the threaded studs being chamfered means that there are only maybe 8 turns engaged with a very loose fit. I know only 3-4 threads engaged are really doing all the work, but the loose fit just started eating away at me.

The things you circled are the ends of the camlock studs from the chuck side of the backplate, with the little locking screw holes beside them.

You can see the plastic backplate / cover in the 2nd (removed and lying above) and 3rd pic (installed) in post #30 of this thread - the one where I start talking about this chuck.

Ah, I see. The plastic thing is not a backplate, it's an internal cover of some kind. The backplate itself is still cast iron. I'm good with that. For me it doesn't matter anyway as I will need a D1-5 backplate which Vevor does not offer.

I didn't fully explain my misgivings with the backplate. The locking screws were the first thing I noticed not being right. Later on I became uncomfortable with the fit of the threaded cam studs in the back plate - very loose fit for a relatively fine thread, plus with the clearance hole being drilled and extra few millimeters, and the ends of the threaded studs being chamfered means that there are only maybe 8 turns engaged with a very loose fit. I know only 3-4 threads engaged are really doing all the work, but the loose fit just started eating away at me.

I understand. That would bother me too.

I suppose you could clock it 60 degrees or so.

But really, is it bad enough as to be worth that much work? Only you can answer that.

I'd be inclined to just use it as is. For one thing, I don't think a 6 jaw needs to be as robust as a 3 or 4 jaw. It's really intended to hold springy parts better than a 3 jaw would (ie reduce the "everything is rubber" tendency of parts to deform when clamped at just 3 points. Something that springy prolly doesn't need much strength in the chuck mount. And I never gronk on my cam locks anyway. It isn't necessary and could damage them.

The things you circled are the ends of the camlock studs from the chuck side of the backplate, with the little locking screw holes beside them.

Really! They appear to have allen hex heads on them! But I can't blow up the photo enough to see that for sure. In any case, I accept your explanation.

Thank you!

Now I need to decide whether or not I want one bad enough to deal with all that.....

FYI - Vevor responded - they don't see an issue, so I'm on my own. I think I will redrill and tap the stud holes, I'm just not comfortable with the thread fit either. Will be a nice little project to refamiliarize myself with the shop after the summer away from it.

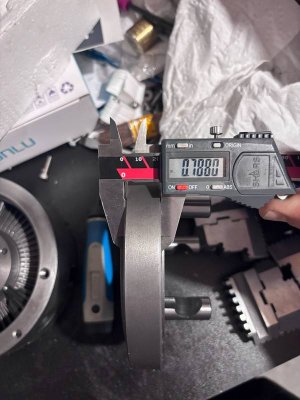

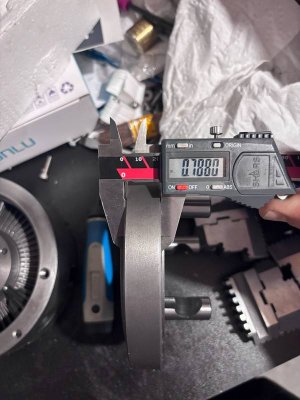

So we are on the same page, I include a screen shot of the lock screws you posted a while back.

Notwithstanding your concerns about the cam lock studs themselves, I would not be concerned about the lock screws enough to relocate them. It isn't necessary. They do not carry any significant load. Their only purpose is to prevent the cam lock studs from rotating while not installed on the spindle.

Nonetheless, as your second photo above shows, they don't do what they are supposed to do and that has to be fixed.

To work properly, they should fully engage the indexing relief on the camlock stud. A washer beneath the screw would work, but you would need a stack of them which would increase the odds of the stack coming loose. I'd make custom sleeves instead that raise the head of the screw just shy of the backplate surface. You wouldn't want them proud because that would interfere with the integrity of the backplate to spindle connection.

If this were mine, I'd identify which of the three screws is the shallowest and then make 3 steel sleeves (very thick washers) that would raise that screw just shy of the surface. Just use a depth gauge (caliper depth function is fine) to measure the backplate surface to screw head dimension and then make 3 sleeves say 10 to 15 thou less than that. Easy peasy on your lathe. Precision is not required.

basically all the issues are with the backplate, the chuck is fine except for the copious amount of deburring required. So if you are making your own backplate, then its pretty much a non-issue.

I put the chuck all back together after deburring, and then I realized that I missed 3 places - the edge of the holes for the pinions... I'll do that later today.

And yes, I'm just going to make a spacer / thick washer to space the locking screws up. As long as they are tightened they aren't going anywhere - they're trapped by the spindle nose so can't really back out. Its just about having it be to my liking a the end of the day.

I put the chuck all back together after deburring, and then I realized that I missed 3 places - the edge of the holes for the pinions... I'll do that later today.

And yes, I'm just going to make a spacer / thick washer to space the locking screws up. As long as they are tightened they aren't going anywhere - they're trapped by the spindle nose so can't really back out. Its just about having it be to my liking a the end of the day.

@Mike R - On the strength of your report and your answers to my questions, I went ahead and ordered one too. I had some Vevor $ so all in it was well under 300.

Although I have a few D1-5 back plates, I think I'll check out what the local reseller has. As you said, there isn't enough meat on the register to do set-true the normal way. So I'm thinking I'd like to get a 7" backplate so I can sink the whole chuck into the backplate. The other alternative is to make a third adapter plate in the sandwich to adapt a regular backplate to the chuck. Both methods would use the chuck OD as the SetTru register since the existing register is too small.

Although I have a few D1-5 back plates, I think I'll check out what the local reseller has. As you said, there isn't enough meat on the register to do set-true the normal way. So I'm thinking I'd like to get a 7" backplate so I can sink the whole chuck into the backplate. The other alternative is to make a third adapter plate in the sandwich to adapt a regular backplate to the chuck. Both methods would use the chuck OD as the SetTru register since the existing register is too small.

@Mike R - mine came today.

To avoid surprise, I think it's a beauty.

Doesn't seem to have as many burrs as yours. Go figure. Mine is a wee bit tight - but very evenly tight which is WAAAY better than loose. I expect it to loosen up properly after some use. I might just run it in and out a few dozen times till its happy. The only burrs I can see or feel are around the chuck key holes where they don't matter. I may leave them as is or fix them at a future date. Some of the machined edges are on the sharp side but not so sharp as to cut you. I don't think I'll bother trying to make them better.

Unless I can modify it to 6 stud, I'll be selling/trading the backplate as is so I didn't even bother looking at it other than to check the lock screw depth for your benefit. Mine is the same as yours. If I tighten them, the cam studs will turn right over the screw head. Looking at mine, I have zero qualms about my previous advice to make sleeves to space out the screws 150 thou or so. I think 10 to 15 thou under the surface is ideal.

The chuck itself is really nice. I was a bit surprised to find that the smallest OD it will hold when fully closed is actually a fairly big OD. It looked like about 3/8ths. So I tested it and found that 21/64ths is loose and it will hold 11/16ths. Prolly best to assume its smallest size is about 3/8ths. But in hind sight it's either that or a much smaller jaw surface. I'm ok with the choice of comprise they made. For small parts I almost always use my 5C collet chuck anyway.

I was also pleasantly surprised to discover that the key is the same size as the one for my 3 and 4 jaw chucks. My Smile Key and 12V Milwaukee Drive key will work just fine on it. Nice! I really dislike having 500 different chuck key sizes.

Thanks for "Leading The Way" on this one Mike! It will put an end to what seemed like a never-ending quest for a decent 6 jaw chuck.

Now to work on finding or making the right D1-5 backplate or backplate/spacer combination.

To avoid surprise, I think it's a beauty.

Doesn't seem to have as many burrs as yours. Go figure. Mine is a wee bit tight - but very evenly tight which is WAAAY better than loose. I expect it to loosen up properly after some use. I might just run it in and out a few dozen times till its happy. The only burrs I can see or feel are around the chuck key holes where they don't matter. I may leave them as is or fix them at a future date. Some of the machined edges are on the sharp side but not so sharp as to cut you. I don't think I'll bother trying to make them better.

Unless I can modify it to 6 stud, I'll be selling/trading the backplate as is so I didn't even bother looking at it other than to check the lock screw depth for your benefit. Mine is the same as yours. If I tighten them, the cam studs will turn right over the screw head. Looking at mine, I have zero qualms about my previous advice to make sleeves to space out the screws 150 thou or so. I think 10 to 15 thou under the surface is ideal.

The chuck itself is really nice. I was a bit surprised to find that the smallest OD it will hold when fully closed is actually a fairly big OD. It looked like about 3/8ths. So I tested it and found that 21/64ths is loose and it will hold 11/16ths. Prolly best to assume its smallest size is about 3/8ths. But in hind sight it's either that or a much smaller jaw surface. I'm ok with the choice of comprise they made. For small parts I almost always use my 5C collet chuck anyway.

I was also pleasantly surprised to discover that the key is the same size as the one for my 3 and 4 jaw chucks. My Smile Key and 12V Milwaukee Drive key will work just fine on it. Nice! I really dislike having 500 different chuck key sizes.

Thanks for "Leading The Way" on this one Mike! It will put an end to what seemed like a never-ending quest for a decent 6 jaw chuck.

Now to work on finding or making the right D1-5 backplate or backplate/spacer combination.

Glad its to your liking.

Yes, I noticed the rather large minimum clamping diameter, but for small stuff the 5C does the job, or the ER32 adapter in the 5C.

Also, mine had a lot of grinding dust inside, be sure to check and clean yours out.

I also noticed its the same key as my 3 jaw, so that is a bonus. Now I can leave a chuck key at the mill (one of the reasons for this chuck was to have a 2nd chuck for holding things in the 4th axis on the mill while I have something chucked up in the 3 jaw on the lathe - do I get distracted much / have ADHD? maybe).

Yes, I noticed the rather large minimum clamping diameter, but for small stuff the 5C does the job, or the ER32 adapter in the 5C.

Also, mine had a lot of grinding dust inside, be sure to check and clean yours out.

I also noticed its the same key as my 3 jaw, so that is a bonus. Now I can leave a chuck key at the mill (one of the reasons for this chuck was to have a 2nd chuck for holding things in the 4th axis on the mill while I have something chucked up in the 3 jaw on the lathe - do I get distracted much / have ADHD? maybe).

do I get distracted much / have ADHD? maybe).

An active mind is a good thing I think......

Question - do you like everything neat and tidy or are you happier with organized chaos like me.

I have had a personality assessment and they were confused! I'm one foot in organized chaos and one foot in neat and tidy. I flip flop between the 2, depends on the situation, space, task and people surrounding. More neat and tidy at work, home shared spaces etc., but workshop and garage devolve into chaos

I'm one foot in organized chaos and one foot in neat and tidy. I flip flop between the 2, depends on the situation, space, task and people surrounding.

You are not alone. I've known more than a few like that. I was just curious.

This got me thinking about what I found more frustrating - having an organized shop where I can't find a tool because it isn't back where it belongs, or being in a chaotic shop where I "knew" where everything should be and not finding the item...You are not alone. I've known more than a few like that. I was just curious.

I think its the later - if I think I know where it is and its not there - then my brain failed me. Turns out thats not always the case with a teenage boy in the house grabbing tools and leaving them around, but still.

The real kicker is when I find a tool days/weeks/months/years later that was stashed like a squirrel stole it. Like on top of a cabinet, or one of those spaces on top of a basement wall by the rim joist, or some other tiny, inconspicuous space cause that was the only space at the time where it wouldn't get away from you. Happens more with home repair / reno but occasionally with car repair or machining too. (i.e. the wrench under the intake - what a classic).

Only occasionally do they show up in the wash, nice and clean!

Don't worry, this problem goes away with age. You mention teenagers so you're not there quite yet. Somewhere in your future you'll go over to the place where you know the thingamee is and you'll look at the spot and ask yourself " what am I looking for ?" 🙄I "knew" where everything should be and not finding the item...

I think its the later - if I think I know where it is and its not there - then my brain failed me.

already there, the other kid is older and out of the house, but the one still here just turned 19 so last year of "teenager" and legally an adult.

I regularly now go into a room and have to turn back to where I came from to figure out why I had gone there in the first place...retracing my steps seems to be the most regular form of exercise I get...

I regularly now go into a room and have to turn back to where I came from to figure out why I had gone there in the first place...retracing my steps seems to be the most regular form of exercise I get...