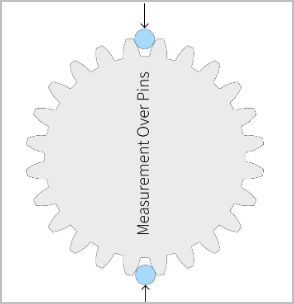

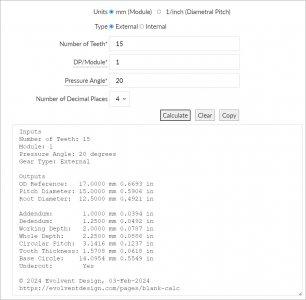

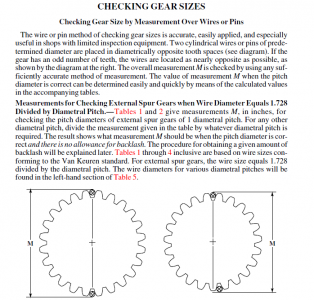

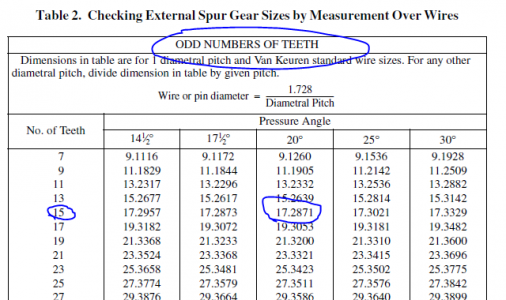

I found this website that calculates tooth depth of spur gears using user defined gage pins diameters making contact between 2 neighbor teeth as per their sketch. Useful for measuring an existing gear, or cutting a new gear because you could compare the actual distance vs the theoretical distance. But what about odd tooth gears where the valleys will not align vertically like the reference sketch? Unless I missed it, the website doesn't even mention this. Unless they factor the odd tooth into the calculation & its still a pin to pin measurement (which seems odd & very undefined).

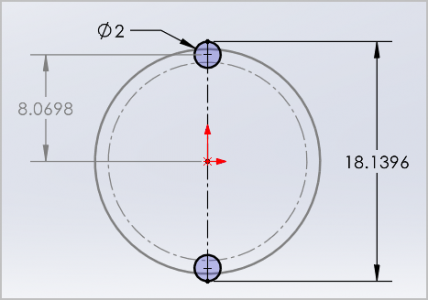

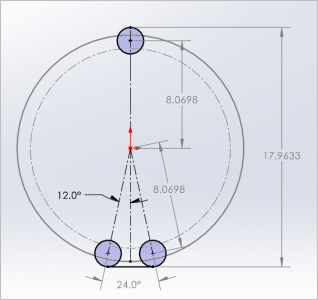

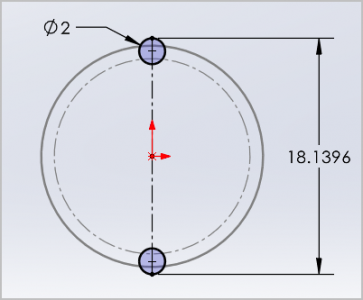

Assuming them mean theoretical vertical distance I made a mod-1, 15T gear, 20-deg PA to see if I could fake it. I transposed the resulting vertical distance of 18.1396 mm over 2 mm diameter pins, but then assume 2 pins within the bottom 2 teeth valleys 360 deg / 15T =24 deg apart, but at the same radius in order to still measure vertically at their outer tangents. Surely there must be a better way. Does anyone have experience with this? Is there a formula relationship to OD & PD maybe? Part of what makes this tricky *I think* is if the cutter profile is advancing into the blank X amount, its not like a cutting tool reducing OD by 2X because the cutter has an involute profile and that profile tangency to pin is what is driving the pin to pin measurement

evolventdesign.com

evolventdesign.com

Assuming them mean theoretical vertical distance I made a mod-1, 15T gear, 20-deg PA to see if I could fake it. I transposed the resulting vertical distance of 18.1396 mm over 2 mm diameter pins, but then assume 2 pins within the bottom 2 teeth valleys 360 deg / 15T =24 deg apart, but at the same radius in order to still measure vertically at their outer tangents. Surely there must be a better way. Does anyone have experience with this? Is there a formula relationship to OD & PD maybe? Part of what makes this tricky *I think* is if the cutter profile is advancing into the blank X amount, its not like a cutting tool reducing OD by 2X because the cutter has an involute profile and that profile tangency to pin is what is driving the pin to pin measurement

Gear Measurement over Pins Calculator | Evolvent Design

Make sure your gear is the right size by checking its dimension over pins or wires. This measurement over pins calculator works on module and diametric pitch gears of all sizes