slow-poke

Ultra Member

I often hear comments to the effect "I don't want CNC because I want to be able to use my machine manually.

So do I often. One does not preclude the other.

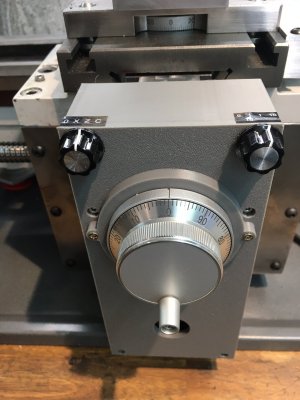

Images of manual controls for my lathe.

There are two rotary switches and a MPG.

- The MPG emulates the hand wheels, it's graduated in 100 "ticks"

- The first rotary switch, lets you select either: nothing, the X axis, the Z axis, or the compound axis

- The second rotary switch lets you select either: 0, 0.0001", 0.001", or 0.01" per tick

-Action video showing carriage moves with MPG (Z-axis) https://www.dropbox.com/scl/fi/vkkw...ey=k5ghuzzkk6mujk25axft44q8e&st=m2ldco40&dl=0

So do I often. One does not preclude the other.

Images of manual controls for my lathe.

There are two rotary switches and a MPG.

- The MPG emulates the hand wheels, it's graduated in 100 "ticks"

- The first rotary switch, lets you select either: nothing, the X axis, the Z axis, or the compound axis

- The second rotary switch lets you select either: 0, 0.0001", 0.001", or 0.01" per tick

-Action video showing carriage moves with MPG (Z-axis) https://www.dropbox.com/scl/fi/vkkw...ey=k5ghuzzkk6mujk25axft44q8e&st=m2ldco40&dl=0