-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tips/Techniques Making the Square Drive hole in a custom socket.

- Thread starter Susquatch

- Start date

Tips/Techniques

140mower

Don

...... except that the shaper drills very poor holes. 🙄 😉No need for a square hole at all: make the tool 1/2” longer and cross drill for a Tommy bar.

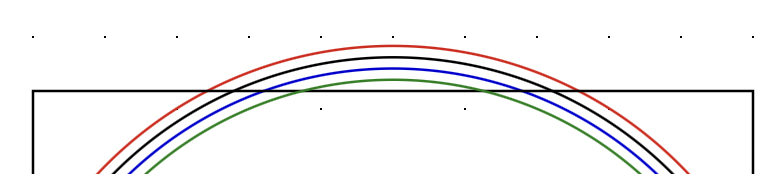

Like this:

View attachment 62195

RobinHood

Ultra Member

You are not wrong there…...... except that the shaper drills very poor holes. 🙄 😉

I agree - maybe it’s time for you to make rotary broach - just saying

Ya, I might just do that anyway. I like making tools for my tools for my tools......

No need for a square hole at all: make the tool 1/2” longer and cross drill for a Tommy bar.

Yes, that method was discussed in post 13 and 14. It's the easiest solution by a very wide margin. 50 bucks isn't bad at all compared to the OEM Volvo tool. I am surprised to see it for sale though.

The other easy solution is to fit a stub into the end and mill a nut onto it.

But I think it's more important to help my 3 grandsons make something for their dad and see how 4 shop machines can be used to make stuff like a cool tool for their dad.

mickeyf

Ultra Member

I skipped from the first page to here so this may be a repeat, but to avoid welding I'd buy a socket from the Habitat for Humanity store for a buck or so, and press fit it into the appropriately bored pipe after shortening it. Throw in some loc-tite if you like, but I have found that a properly done interference fit is every bit as strong as a weld. Downside - you don't get to play with the shaper. It's also a different set of lessons for the kids, but they should know about interference fits too.

The rule of thumb I learned was one thou larger than the hole size for every inch of diameter, but if you have a beefy enough press you can double that or even more depending on the material, and that thing ain't never comin' apart. I'd guess that in your case the wall thickness of the pipe would be the limiting factor. I also like to turn down the part entering the hole to a slip fit to ensure that it starts straight - maybe 20 thou or so if your part can afford that.

The rule of thumb I learned was one thou larger than the hole size for every inch of diameter, but if you have a beefy enough press you can double that or even more depending on the material, and that thing ain't never comin' apart. I'd guess that in your case the wall thickness of the pipe would be the limiting factor. I also like to turn down the part entering the hole to a slip fit to ensure that it starts straight - maybe 20 thou or so if your part can afford that.

ChazzC

Ultra Member

Back when I (and you) was very much younger, Kent-Moore (a division of GM) would sell OEM special tools & manuals to anyone who had the money (pots of it) to buy them.Yes, that method was discussed in post 13 and 14. It's the easiest solution by a very wide margin. 50 bucks isn't bad at all compared to the OEM Volvo tool. I am surprised to see it for sale though.

Back when I (and you) was very much younger, Kent-Moore (a division of GM) would sell OEM special tools & manuals to anyone who had the money (pots of it) to buy them.

Early in life, I learned that public libraries got a special deal on hardcover copies of manuals. If you spilled coffee in them you had to pay a very fair price for a new copy and got to keep the old one.

I also learned that the dealers would let you visit their shops and inspect their special tools. That's how I became interested in drafting. I also made a lot of special tools for myself and my friends back in those days.

Special tools! LOL! Ever been around airplanes? Pretty sure, based on my long contact, that there was some clown in a back room, designing effed up tools, then issuing out the drawings requiring that the guys on the shop floor design their parts around the mangled and welded remains of a half dozen Snap-On wrenches!Early in life, I learned that public libraries got a special deal on hardcover copies of manuals. If you spilled coffee in them you had to pay a very fair price for a new copy and got to keep the old one.

I also learned that the dealers would let you visit their shops and inspect their special tools. That's how I became interested in drafting. I also made a lot of special tools for myself and my friends back in those days.

And, while I say that tongue in cheek, I'm not entirely sure I am not wrong!

Gotta say, Public Libraries, and esp., the Inter-Library loan system, were some of the few things that I thought I got my Property Tax dollars, out of!

I frequently got Inter-Library loan books that were out of Reference libraries, from places like Sandia National Laboratories, or NASA, as well as from several University Libraries around the Excited States, and most of those were books that, If you were a Local, you were not allowed out of the building with! Such a GREAT way to preview the books you want to buy, to see if they actually fit the need you think they might!

Last edited:

ChazzC

Ultra Member

Further drifting . . .Special tools! LOL! Ever been around airplanes? Pretty sure, based on my long contact, that there was some clown in a back room, designing effed up tools, then issuing out the drawings requiring that the guys on the shop floor design their parts around the mangled and welded remains of a half dozen Snap-On wrenches!

And, while I say that tongue in cheek, I'm not entirely sure I am not wrong!

Gotta say, Public Libraries, and esp., the Inter-Library loan system, were some of the few things that I thought I got my Property Tax dollars, out of!

I frequently got Inter-Library loan books that were out of Reference libraries, from places like Sandia National Laboratories, or NASA, as well as from several University Libraries around the Excited States, and most of those were books that, If you were a Local, you were not allowed out of the building with! Such a GREAT way to preview the books you want to buy, to see if they actually fit the need you think they might!

Back when I was consulting I made regular trips to the State Library of Pennsylvania (think of it as a miniature Library of Congress): they had reference material other libraries didn't, but you had to go there to borrow or review. This was back in the 90's, so online resources were limited, although I think you could search their catalog once you were registered. I forget what the topic was but on one visit I had to use a book support and wear white gloves.

I still have my card (and that rom the local Penn State campus), but probably need to get it updated. I also still have the Microfiche that they copied for me and an operating fiche reader.

ChazzC

Ultra Member

Only recently Apple started publishing manuals and lending out special tools so anyone can make repairs (have to pay a hefty deposit & shipping costs, and there are penalties if you don't send them back on time). All thanks to the Right to Repair movement.Early in life, I learned that public libraries got a special deal on hardcover copies of manuals. If you spilled coffee in them you had to pay a very fair price for a new copy and got to keep the old one.

I also learned that the dealers would let you visit their shops and inspect their special tools. That's how I became interested in drafting. I also made a lot of special tools for myself and my friends back in those days.

Microfiche. LOL! Very familiar! The parts catalog for one of the aircraft I worked on at the beginning of my career was all on fiche pages. Grumman CS2-F, Tracker, aka, the Stoof.Further drifting . . .

Back when I was consulting I made regular trips to the State Library of Pennsylvania (think of it as a miniature Library of Congress): they had reference material other libraries didn't, but you had to go there to borrow or review. This was back in the 90's, so online resources were limited, although I think you could search their catalog once you were registered. I forget what the topic was but on one visit I had to use a book support and wear white gloves.

I still have my card (and that rom the local Penn State campus), but probably need to get it updated. I also still have the Microfiche that they copied for me and an operating fiche reader.

Gods help you if some clown missed the proper place to return the film to in the file index...

.. I missed this thread (oops) so I'm very late to the party. Just about every option has been offered (sometimes several times), but I think there was one that was missed.

... "I know a guy..." that has a 3/4 square broach for sale, at possibly a super price... Jus' sayin'

... "I know a guy..." that has a 3/4 square broach for sale, at possibly a super price... Jus' sayin'

I have the square 1/4” one

now to fill in, all we need is the 3/8 and 1/2 😛

I'll try and get the 1/2. Then all we need is someone to get the 3/8, and we will be a foursome!

We could just ship back and forth as needed!

Question - how does a square broach work? One edge at a time with a wedge, or all 4 corners at once? Or?

You drill a round hole, smaller than the square will become.I'll try and get the 1/2. Then all we need is someone to get the 3/8, and we will be a foursome!

We could just ship back and forth as needed!

Question - how does a square broach work? One edge at a time with a wedge, or all 4 corners at once? Or?

Insert the pilot align the flats to your liking, and press through with an arbor press or hydraulic press, using care to not tip the part, or allow the broach to be pressed in any way except straight, else you get to buy another broach.

All four corners are cut at the same time, as the broach has a series of increasing sized teeth, each taking a larger cut out of the hole.

All four corners are cut at the same time, as the broach has a series of increasing sized teeth, each taking a larger cut out of the hole.

So option B then. Makes the most sense but might require a pretty big press for a 3/4 broach.....

ChazzC

Ultra Member

Downwindtracker2

Ultra Member

Now that we have a square hole, there is some other elements of a good design. I will use the correct term, socket wrenches have come a long way in even my life time. The floor has been raised but the ceiling hasn't been. You can walk into CTire and buy a pretty fine socket. At the square end, the lead-in is nicely chambered and there are four healthy dimples . Heck, I bought new 1/4" sockets just to get those features . My buddy gave me a bucket of his Dad's old rusty boat tools , in there, there were Canadian made Gray sockets. They didn't have dimples or even holes . I cleaned them up and made up a jig and drilled holes. I put them in my tool box in the truck canopy were they ended up being stolen. After all that, I bought a CTire 400 piece set for $ 99. chuckle.