-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

machine paint?

- Thread starter Canadium

- Start date

Canadium

Ian

That was a little over a year ago. All I remember is that it was 2 bucks cheaper than the Home Depot website, and closer for me to drive. maybe 17 bucks/gallon? I get a tiny discount being registered as a business, so exact pricing escapes me.

In my area (Ontario GTA) Home Depot and many other places retail acetone for $30/gallon. Princess Auto occasionally has on sale for $25. I'm sorry to say I have not been very impressed with Dulux near me. A gallon of their Metalclad "Urethane fortified alkyd paint" retails for $68/gallon. This paint appears to be equivalent to the old TSC stores "Implement and Equipment Enamel" that I was very impressed with but is no longer sold. I have just yesterday found something else nearby which appears to be an equivalent at my nearby Home Hardware store. It is also a "Urethane fortified alkyd paint". It's their in house brand called Beauti-tone Rust Paint. Made in Canada and sold by Canadians! It retails for $49/gallon and no membership registration BS is required. I think I will run with it and see how it works.

That was a little over a year ago. All I remember is that it was 2 bucks cheaper than the Home Depot website, and closer for me to drive. maybe 17 bucks/gallon? I get a tiny discount being registered as a business, so exact pricing escapes me.

When exact pricing escapes you that's the first a sign off? I forgot! LOL

@Canadium - Sherwin Williams bought General Paint, and hence it's factory. The industrial paints are all General paint (probably changed now due to more regulations) made in the same General paint factory, in Canada. (I think it is B.C. - I even knew which city at one point, but that was then)

I can still special order the acetone based primer, which was the best primer I ever used, but now double the price. It was harder than any paint I ever used, but it was of course, tricky to use.

If you get a company account (use a 'trade name' - there is no requirement for it to be a registered trade name, and you'll get a discount). I used to buy a lot of industrial paint when I had my own company, hence the info and suggestions.

I can still special order the acetone based primer, which was the best primer I ever used, but now double the price. It was harder than any paint I ever used, but it was of course, tricky to use.

If you get a company account (use a 'trade name' - there is no requirement for it to be a registered trade name, and you'll get a discount). I used to buy a lot of industrial paint when I had my own company, hence the info and suggestions.

I'm becoming less impressed with Home Depot & similar big box mafia stores. Maybe its a function of supply chain or tariffs or whatever. I use them selectively as a necessary evil until Amazon delivers 2x4s, but I try to always check prices. Some things are in line, others are out of whack. But they have been a great stock to hold. I guess that makes me 2 faced.

1 gal of acetone HD in Kalispell MT 19.97 USD = 24.16 CAD at todays FX

https://www.homedepot.com/s/acetone?NCNI-5

1 gal of acetone HD Calgary NE, 29.97 CAD = 24% higher

https://www.homedepot.ca/search?q=acetone

1 gal of acetone HD in Kalispell MT 19.97 USD = 24.16 CAD at todays FX

https://www.homedepot.com/s/acetone?NCNI-5

1 gal of acetone HD Calgary NE, 29.97 CAD = 24% higher

https://www.homedepot.ca/search?q=acetone

Attachments

Canadium

Ian

@Canadium -

If you get a company account (use a 'trade name' - there is no requirement for it to be a registered trade name, and you'll get a discount). I used to buy a lot of industrial paint when I had my own company, hence the info and suggestions.

@Dabbler There seem to be many suppliers in my area that either prefer or insist on business clients. So I have been wondering for some time if I should not at least fake having a business. I have owned businesses in the past (not metal working related) and I know from experience that the paper work with Revenue Canada is a big PIA. A good reason not to go there. It all depends what kind of proof of authenticity the supplier asks for. If they want your CRA business number thats a problem. If they just want a business name thats easy to fake. In my case my local Dulux wants a bank account in my business name. I'm not sure I want to go there. They certainly do offer big discounts for a business. If I did register with them as a business my price for the Metalclad would only be about $45!

Polyurethanes have extremely hazardous fumes and hence probably not good for hobbyist use..

I mostly agree with your sizing up the paints, but polyurethanes as I understand aren't that simple. The two part catalyzed polyurethane like an Imron have isosynates. Awesome paint, but you want positive pressure suit with air supply etc. Potentially deadly and not for the home shop. otoh, there are relatively safe moistue curring single part polyurethanes like POR 15. I haven't used it, but its supposed to near bullet proof. It does iirc have a short shelf life and no shelf life after opening it

In the garage, where the real machine tools reside, I scrape and recondition and make for perfect functionality but rarely bother painting because after a year of coolant & chips they'll look like crap again. In the basement where the pretty machines reside, I airbrush PPG line 7 enamel with a bit of talc to get rid of the gloss....they've held up well, but its far less hostile environment than the larger machine tools see.

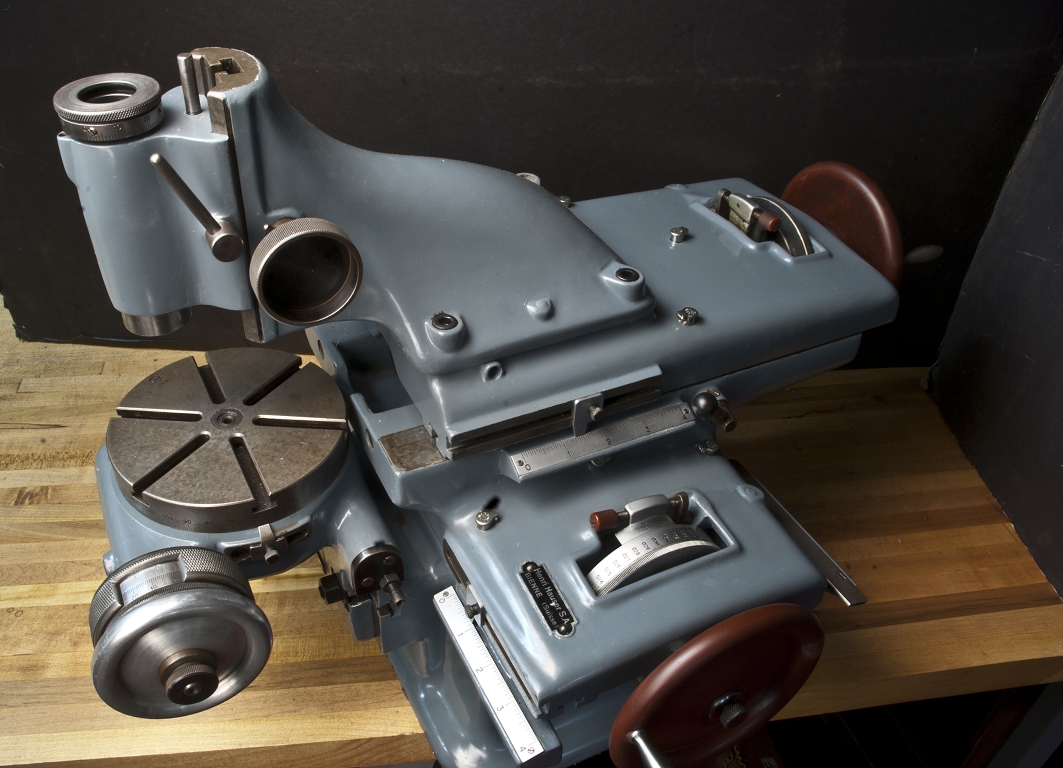

Nice machine. What is it?

I've heard similar things about POR-15, but apparently its like saying BASF or Sherwin Williams - its a brand name / formulator. They make many products lines. The DTM (direct to metal) sounds promising.

Limited color selection though.

https://por15.com/collections/all

Then there is rust prevent line. Suspiciously similar description as Tremclad. Actually more greys & 'machine' colors... unless one fancied a canary yellow mill LoL

And what does rust prevent even mean - an all round tougher paint?

https://por15.com/collections/all/products/rust-preventive-coating

I've heard similar things about POR-15, but apparently its like saying BASF or Sherwin Williams - its a brand name / formulator. They make many products lines. The DTM (direct to metal) sounds promising.

Limited color selection though.

https://por15.com/collections/all

Then there is rust prevent line. Suspiciously similar description as Tremclad. Actually more greys & 'machine' colors... unless one fancied a canary yellow mill LoL

And what does rust prevent even mean - an all round tougher paint?

https://por15.com/collections/all/products/rust-preventive-coating

Last edited:

thanks.....that's a Hauser M1 jig borer. For watch sized stuff. Probably the nicest made machine I've worked on. The dials are graduated in 10ths with feed screw error correction and everything moves like silk. A lot were even sold without a spindle (mine was, just not installed at the moment) and were used for layout work - hole locations for watches made with a special punch for subsequent lathe work.

I thought so. And I also recall seeing a similar pic from somewhere. This guy has the same name LoL

https://www.modelenginemaker.com/index.php?topic=7931.0

If you ever feel like sharing some resto / rebuild pics one day, I'd be very interested & sure it would be appreciated. I've only seen videos of them running, but would love to see one in real life.

So you sprayed this stuff? Did you reduce it at all & if so with what? Did you use any sealer/primer on exposed metal? It looks pretty darn nice to my eye, but you feel it wouldn't be a long lasting finish for metalworking machines in general?

https://www.eddygroup.com/2574099/p/n/ppg-7-814s

Do you do specific watch type work or more interested in restoring machines themselves?

https://www.modelenginemaker.com/index.php?topic=7931.0

If you ever feel like sharing some resto / rebuild pics one day, I'd be very interested & sure it would be appreciated. I've only seen videos of them running, but would love to see one in real life.

So you sprayed this stuff? Did you reduce it at all & if so with what? Did you use any sealer/primer on exposed metal? It looks pretty darn nice to my eye, but you feel it wouldn't be a long lasting finish for metalworking machines in general?

https://www.eddygroup.com/2574099/p/n/ppg-7-814s

Do you do specific watch type work or more interested in restoring machines themselves?

i like tremclad, its cheap, its easy to source, touch ups are easy, and so long as you do your prep properly and roll/brush it on in thin coats it turns out pretty well and is reasonably durable

of course just about any 2k product is going to beat the ol tremclad, but then you need to deal with isocyanates, mixing, spraying, clean up....and in 2 years when its time to touch something up that 100$ gallon you had to buy is no longer good...i have painted plenty of motorcycles and automotive parts with 2k products, it turns out awesome but for the work involved i dont think i would ever bother on a machine tool

powder is easy to get, couple clicks on the internet at its at your door in a few days (prismatic powders), that being said with all of the cast pieces on a vintage lathe it would be extremely labor intensive to powder coat, every cast piece would need to be heated up and off gassed for probably an hour, and even then who knows if you would get all the junk out of the pors, something you wouldnt find out untill you cured the powder and found pinholes and craters every where

of course just about any 2k product is going to beat the ol tremclad, but then you need to deal with isocyanates, mixing, spraying, clean up....and in 2 years when its time to touch something up that 100$ gallon you had to buy is no longer good...i have painted plenty of motorcycles and automotive parts with 2k products, it turns out awesome but for the work involved i dont think i would ever bother on a machine tool

powder is easy to get, couple clicks on the internet at its at your door in a few days (prismatic powders), that being said with all of the cast pieces on a vintage lathe it would be extremely labor intensive to powder coat, every cast piece would need to be heated up and off gassed for probably an hour, and even then who knows if you would get all the junk out of the pors, something you wouldnt find out untill you cured the powder and found pinholes and craters every where

If you ever feel like sharing some resto / rebuild pics one day, I'd be very interested & sure it would be appreciated. I've only seen videos of them running, but would love to see one in real life.

For this particular machine, it was like new except the paint which was literally falling off in big thick chunks. Other than sand prime cylces and paint, nothing else was needed. I've since bought a microscope for but need to lap it - These were sold with the tooling lapped to the particular machine's bore so the trick is buy one a few tenths larger and lap it in. I have done a fair bit reconditioning and written a lot on it. Currently working on extened piece "reconditioning a lathe"... so there is and will be lots of my scraping projects out there. A Schaublin 70 is on the bench now (will be part of the lathe series), I will put some pics up

So you sprayed this stuff? Did you reduce it at all & if so with what? Did you use any sealer/primer on exposed metal? It looks pretty darn nice to my eye, but you feel it wouldn't be a long lasting finish for metalworking machines in general?

https://www.eddygroup.com/2574099/p/n/ppg-7-814s

I sprayed it with a paasche airbrush with the largest tip you get the. The paint is really thick and needed a lot of thinning to become sprayable with such a small noozle. I kept coats thin and it didn't run. They don't recommend thinning but it dried properly. I probably one of the few characters to try it with an airbrush lol. Thinning was just paint thinner. I have a commercial painter at work and got his advice on what paint etc.

By all accounts its a very good industrial enamel, I just don't think any paint (perhaps short a single part polyurathane like the POR 15) that you can put on at home has much of a chance against sharp large hot raggedy edge chips and coolant. But its also person choice. These little Swiss machines are like sculpture and I just like them looking nice, whereas the bigger ones are a lot of work and see a lot more volume of big hot chips and coolant.

Sprayed on to a mottle of filler primer, spot putty and metal.

Do you do specific watch type work or more interested in restoring machines themselves?

Reconditioning (correcting all the bearing surfaces) is more a means to end vs something I do as a hobby. For me, I just really like using best of breed machines in pristine condition and they economic way to bring that about is to recondition them (and I'm more than a bit of a toolaholic). Really what I like doing is making model engines, but building my shop has recieved a lot of attention. My problem is I buy something because I can recondition a machine in an evening....in my head. Try to finish the current 500 more projects to get back to models. Horology is a more recent interest. I'm now moderately competent at servicing watches and making basic parts like a balance staff, but I've a ways to go. 🙂

Hi. I found this web site searching for Dulux Metalclad paint. I wanted to brush paint some vintage car parts with a hard wearing paint that would last for some time. I had a couple of parts that were still in good condition with original paint for a comparison. I contacted Dulux, and the v. helpful technician said to send a sample to them for analysis. I did this, the technician sent the parts back at Dulux's cost, with a sample painted on a card, with details listing the necessary palette of colours to mix together for the exact match. I had to search most of Western Canada to find a Dulux shop that had the correct Metalclad base for my application. I finally found one in Kelowna B.C. and the very helpful manager duly mixed the paint for me, and sent it free delivery to Calgary. Admittedly as Canadium found out, it was $68.00 for the 3.4 litre tin, but the paint was worth it. It brushes on very nicely on round tubular parts, but on flat plate, some brush marks show and seem unavoidable. A light sanding with 400 grit wet and dry took the gloss and brush marks away (I couldn't get Metalclad in the necessary base with a satin finish which would have been best). I was advised by a clerk in Calgary that the factory that produces Metalclad had experienced a fire, and that is why it was so hard to find. I didn't need to open an account or complete a membership registration. I could have gained a discount using my small registered company for a one-off purchase, but was prepared to live with the cost as the contractors' line-up in the store was incredible with only 2 staff working. There is a paint manufacturer in Alberta that has most paint type options available supplied in spray rattle cans. I need to spray a few parts in a graphite colour as near or preferably very close to my middle graphite, and this company suggested RAL 7024 or possibly RAL 7026. A few U.S. spray paint suppliers will also sell cans of RAL paint shades matched to your preference in alkyd enamel (like Rustoleum/Painters' Choice/Tremclad) and other paint type options, and one company includes British Standard colours. It seems that some U.K. race car manufacturers originally preferred British Standard military paint specifications for crack detection purposes on their space-frames, but then possibly kept buying it because military surplus stores had tons of battleship grey to get rid of cheaply?In my area (Ontario GTA) Home Depot and many other places retail acetone for $30/gallon. Princess Auto occasionally has on sale for $25. I'm sorry to say I have not been very impressed with Dulux near me. A gallon of their Metalclad "Urethane fortified alkyd paint" retails for $68/gallon. This paint appears to be equivalent to the old TSC stores "Implement and Equipment Enamel" that I was very impressed with but is no longer sold. I have just yesterday found something else nearby which appears to be an equivalent at my nearby Home Hardware store. It is also a "Urethane fortified alkyd paint". It's their in house brand called Beauti-tone Rust Paint. Made in Canada and sold by Canadians! It retails for $49/gallon and no membership registration BS is required. I think I will run with it and see how it works.

P.S. Mcyver's M1 jig borer looks awesome in the shade of grey he chose with a semi flat or satin finish - with the aid of talc no less!

Cheers, HB.

Your on the right road when you investigated the DULUX Paints.Good points Dabbler. Yes I'm off to the fire dept dropoff myself soon to make my bi-annual journey of expired paint and similar $$ chemical donations.

Do you recall when you bought Dulux 4318? I googled the website & that product number didn't come up. They have 2 lines under specialty paint (or inserting metal into their search bar). A quick dry waterborne alkyd & what they call Metalclad. The alkyd I get the impression is more for less strenuous purposes? The Metalclad loos like a fit but pretty basic color selection.

https://www.dulux.ca/diy/products/specialty-paints

https://www.dulux.ca/diy/products/specialty-paints/dulux-x-pert-waterborne-alkyd

https://www.dulux.ca/diy/products/specialty-paints/Dulux-Metalclad

Part of what makes Tremclad hard to define is they make so many products, sometimes under or hyphenated Rustoleum line. I was under impression Tremclad liquid (in a can), what they call oil based or rust paint (goofy words IMO) is an Alkyd. Of course manufacturer formulations vary so Alkyd-A may be better than Alkyd-B. But Tremclad also makes 'rust' paint in a spray bomb (alkyd?) and another line they say enamel and another line in high heat and.... the only common word is 'rust' which probably came from their marketing department to appeal to weekend warriors.

https://www.rustoleum.ca/product-catalog/consumer-brands/tremclad/rust-paint

https://www.grainger.ca/en/product/PAINT-TREMCLAD-FLAT-BLACK-1-QUART/p/RLM254932

I think Alkyd used to generally mean 'tougher' paint, but especially now with different binders, VOCs, environmental, disposal guidelines... things have changed. Hard to know what you're buying. My buddy was talking about catalyzed water based lacquers for interior use ...strings of words you wouldn't see on the same can label years ago.

https://www.doityourself.com/stry/all-you-need-to-know-about-alkyd-paint

The parent company of DULUX is ‘PPG’.

One of the best automotive and equipment coating companies in the business.

One of our current customers uses a digital scanner to match the colour tone and usually works with SHOPLINE #ALK-200 (Another PPG paint family that is specific for machinery).

Seems like paint companies are getting bought, sold & swallowed like many other companies, so who knows what's under the lid anymore. Long time ago I used to spray HOK (House of Kolor). Really popular with the hot rod crowd. You could buy small quantities of all kinds of cool colors, all the components worked with one another. They got bought by Valspar. Then I think Sherwin Williams bought Valpsar. All I know is the price went through the roof. When I had some rattle cans computer matched recently I bought some 2K clear under the KAPCI name which was significantly less expensive than the more common names. Never heard of them before. But not like I'm in the Biz. What little I messed with the clear, its good stuff.