-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking into 3d printing

- Thread starter WilliamTom

- Start date

Sorry, I miss wrote. It was Dabbler not Sasquatch who saw the Prusa XL on his swing through this area. Opps

Pierre

Oh good. I was totally accepting your version and thinking I'm losing it faster than I thought......

slow-poke

Ultra Member

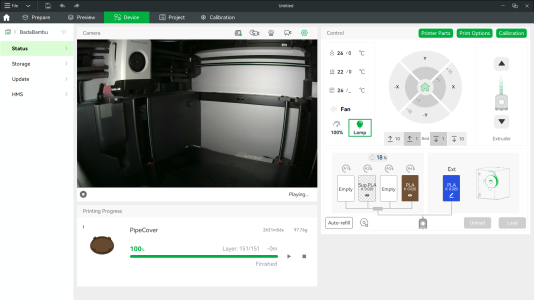

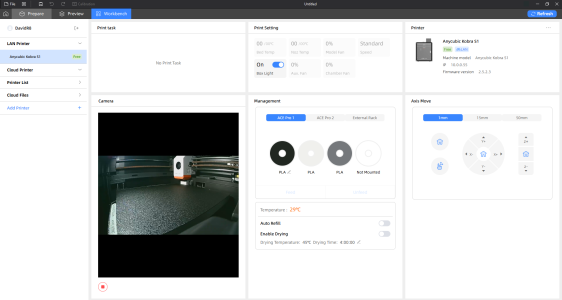

David,Very pleased with my Anycubic Kobra S1 with the Ace Pro. Not had a failed print yet and I have about 250 hours on it.

I have not done any multicolour prints but the ease of changing colours and the built in dryer is worth the cost.

Kobra S1 arrived and I made some time to power it up. Seems to print well ( just PLA so far).

1) are you able to send files from your PC to the printer via WiFi?

2) What version of slicer are you using?

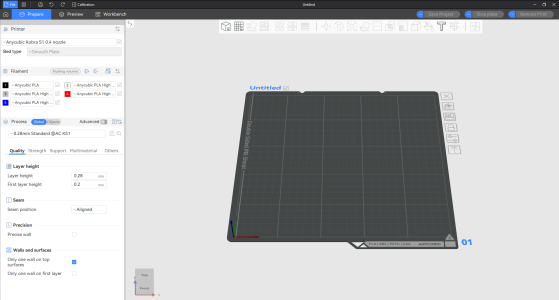

I'm using the Anycubic slicer as it allows LAN mode (vs. cloud) connection to the printer. It's a fork of Orca slicer.David,

Kobra S1 arrived and I made some time to power it up. Seems to print well ( just PLA so far).

1) are you able to send files from your PC to the printer via WiFi?

2) What version of slicer are you using?

slow-poke

Ultra Member

What version of Anycubic slicer?I'm using the Anycubic slicer as it allows LAN mode (vs. cloud) connection to the printer. It's a fork of Orca slicer.

(BTW looks to be a derivative of Prusa slicer to my untrained eye)

When I configure Anycubic slicer, I don't see a selection for Kobra S1, only Kobra3, it seems to work, but video I watched shows selection for S1, it might be because laptop I'm running slicer on only has Win7?

Or I'm using wrong version of Anycubic slicer?

What version of firmware are you using on the actual printer?

I do like some of the features:

+ ease of filament loading

+ multiple filaments and dryer

+ one of my Prusa's had the flexible metal hot table plate, but the old Prusa did not

+ better display

+ carbon filter

+ quieter because of enclosure

+ quality seems quite good and good unpacking instructions

+ looks cool!

- I will assume Wifi connect, but I don't have that working yet

- have yet to do anything with the camera, have you?

I ordered a new hotend thermistor for my old Prusa ($10) looks like an easy fix so I will resurrect it when it arrives and then probably sell both Prusa I don't have the space for a a 3D printer farm;-)

Thanks for your suggestion lots of "+" so far.

Sorry I was mistaken, the Anycubic slicer is a fork of Prusa Slicer not Orca Slicer.What version of Anycubic slicer?

(BTW looks to be a derivative of Prusa slicer to my untrained eye)

When I configure Anycubic slicer, I don't see a selection for Kobra S1, only Kobra3, it seems to work, but video I watched shows selection for S1, it might be because laptop I'm running slicer on only has Win7?

Or I'm using wrong version of Anycubic slicer?

What version of firmware are you using on the actual printer?

I do like some of the features:

+ ease of filament loading

+ multiple filaments and dryer

+ one of my Prusa's had the flexible metal hot table plate, but the old Prusa did not

+ better display

+ carbon filter

+ quieter because of enclosure

+ quality seems quite good and good unpacking instructions

+ looks cool!

- I will assume Wifi connect, but I don't have that working yet

- have yet to do anything with the camera, have you?

I ordered a new hotend thermistor for my old Prusa ($10) looks like an easy fix so I will resurrect it when it arrives and then probably sell both Prusa I don't have the space for a a 3D printer farm;-)

Thanks for your suggestion lots of "+" so far.

This is what I'm using: https://store.anycubic.com/pages/anycubic-slicer

(You will likely have to upgrade your windows version....

My printer is on firmware version 2.5.2.3

Camera is working just fine. It's not 4K to be sure but it does the job well enough for remote monitoring.

Ok, a bit late for some negative comments on my K1C. Was advertised as being capable of 0.2 nozzles but a firmware update made that 0.25mm, which Anycubic doesn't have available (been a few weeks since I checked).

Not planning on using that size much but definitely want to try it out on some small stuff.

My AMS has jammed a time or two. It definitely retracts the filament more than needed and causes it to bunch up, as the cardboard spools are not rotating well. So plastic spools are needed, which is a pain. Need to buy your filament on a plastic spool or rewind yourself or one of the other methods of getting it on a plastic spool.

Firmware is closed. So I can't adjust the parameters for retraction on filament change to fix that myself.

The firmware seems to be programmed in a very linear way for preparation actions when a parallel approach would speed things up - i.e. nozzle temperature changes after probing, waits until homed to raise the temperature when it could be doing that while in motion. Lots more examples but I've been away from it for 3 weeks so I've forgotten about specifics.

On the whole it is much better than my last printer (would be about~7years old now) but still leaves room for improvement in interface (no built in help, no user manual) and no reason to keep the firmware closed, it's all derived from others anyways so no real IP to protect. I suppose it may help cut down on support tickets, but then again so would a user manual and built in help menu (in the slicer)

Not planning on using that size much but definitely want to try it out on some small stuff.

My AMS has jammed a time or two. It definitely retracts the filament more than needed and causes it to bunch up, as the cardboard spools are not rotating well. So plastic spools are needed, which is a pain. Need to buy your filament on a plastic spool or rewind yourself or one of the other methods of getting it on a plastic spool.

Firmware is closed. So I can't adjust the parameters for retraction on filament change to fix that myself.

The firmware seems to be programmed in a very linear way for preparation actions when a parallel approach would speed things up - i.e. nozzle temperature changes after probing, waits until homed to raise the temperature when it could be doing that while in motion. Lots more examples but I've been away from it for 3 weeks so I've forgotten about specifics.

On the whole it is much better than my last printer (would be about~7years old now) but still leaves room for improvement in interface (no built in help, no user manual) and no reason to keep the firmware closed, it's all derived from others anyways so no real IP to protect. I suppose it may help cut down on support tickets, but then again so would a user manual and built in help menu (in the slicer)

Last edited:

slow-poke

Ultra Member

David.Very pleased with my Anycubic Kobra S1 with the Ace Pro. Not had a failed print yet and I have about 250 hours on it.

I have not done any multicolour prints but the ease of changing colours and the built in dryer is worth the cost.

Thanks for this recommendation. I'm really happy with this printer so far.

+ I have only printed about 15-20 items so far with PLA and PETG however the results are quite good.

+ The convenience and easy loading of multiple filaments is a worthy improvement over my old Prusa.

+ Dryer ++

+ Ease of use, nice simple well designed GUI on the actual machine.

+ Thumb up, if it proves to be reliable defiantly two thumbs up.

Creality k1c firmware is open source. You should be able to update and change the options you want. Might have to go to klipper if you really want full control. I think there is an update you can print for the spool holders. Also make sure the enclosure is latched when printing. You can try these with the cardboard spools. It shortens the gap between the spring plates and the spool. https://www.printables.com/model/1103497-creality-k2-plus-cfs-fix-for-small-spools-retractiOk, a bit late for some negative comments on my K1C combo. Was advertised as being capable of 0.2 nozzles but a firmware update made that 0.25mm, which Anycubic doesn't have available (been a few weeks since I checked).

Not planning on using that size much but definitely want to try it out on some small stuff.

My AMS has jammed a time or two. It definitely retracts the filament more than needed and causes it to bunch up, as the cardboard spools are not rotating well. So plastic spools are needed, which is a pain. Need to buy your filament on a plastic spool or rewind yourself or one of the other methods of getting it on a plastic spool.

Firmware is closed. So I can't adjust the parameters for retraction on filament change to fix that myself.

The firmware seems to be programmed in a very linear way for preparation actions when a parallel approach would speed things up - i.e. nozzle temperature changes after probing, waits until homed to raise the temperature when it could be doing that while in motion. Lots more examples but I've been away from it for 3 weeks so I've forgotten about specifics.

On the whole it is much better than my last printer (would be about~7years old now) but still leaves room for improvement in interface (no built in help, no user manual) and no reason to keep the firmware closed, it's all derived from others anyways so no real IP to protect. I suppose it may help cut down on support tickets, but then again so would a user manual and built in help menu (in the slicer)

Sorry, the names of these things is confusingly similar. Mine is the same as David's and Slow-poke's - an Anycubic Kobra S1 Combo (i.e. with AMS) which I abbreviated to K1C.

I haven't had the time or really the need to mess with it, and actually don't want to get into the nuts and bolts of it, I just want it to do what they advertised it doing (0.2mm nozzle). The rest is just optimization and when printing a several hour long print, a few minutes at the front end isn't really helping all that much, only useful on really small prints in the 20 minute to an hour range. I'll be patient and see if / when Anycubic roll out the required updates (just got an email about an new firmware today).

I haven't had the time or really the need to mess with it, and actually don't want to get into the nuts and bolts of it, I just want it to do what they advertised it doing (0.2mm nozzle). The rest is just optimization and when printing a several hour long print, a few minutes at the front end isn't really helping all that much, only useful on really small prints in the 20 minute to an hour range. I'll be patient and see if / when Anycubic roll out the required updates (just got an email about an new firmware today).

Last edited:

Sorry Mike R, Creality has a printer called the K1C so that is why I was confused.

store.creality.com

store.creality.com

Creality K1C Printer: Carbon Fiber Mastery at 600mm/s

Creality K1C, the "Champion of Speed and Skills," delivers at 600mm/s. Tailored for carbon fiber, this 3D printer sets new industry standards.

MrWhoopee

Ultra Member

Rank newb here. I'm absolutely thrilled with my Bambu X1C. It is as close to plug-n-print as one could hope. So far I've used PLA, PLA-CF, PETG, PETG-CF and TPU. It has handled them all without drama. Coming from a metal-working background, I'm amused by complaints about the price. What kind of machine can you get that will produce useable, finished parts, unattended, for USD$1600?

slow-poke

Ultra Member

How about a AnyCubic Kobra S1 with AcePro for $800Cdn delivered ;-)What kind of machine can you get that will produce useable, finished parts, unattended, for USD$1600?