-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking at new lathe -- Opinions and Options

- Thread starter kevin.decelles

- Start date

Ya, you had to look away.... the rationale is that the other lift bar can't be used without crushing the chip shield which in looking at it mow is 100% true

The apron and tooling is moved left so most of the weight is on the primary sling

What was more disturbing was that they had short sling it for the final 3 feet which meant a sling around the chuck assembly. For a 3 foot move .....

But hey, that is a key reason I had it delivered vs buying a grizzly/pm machine and getting it at the border. warranty [emoji51]

Sent from my iPhone using Tapatalk

The apron and tooling is moved left so most of the weight is on the primary sling

What was more disturbing was that they had short sling it for the final 3 feet which meant a sling around the chuck assembly. For a 3 foot move .....

But hey, that is a key reason I had it delivered vs buying a grizzly/pm machine and getting it at the border. warranty [emoji51]

Sent from my iPhone using Tapatalk

Ya, you had to look away.... the rationale is that the other lift bar can't be used without crushing the chip shield which in looking at it mow is 100% true

The apron and tooling is moved left so most of the weight is on the primary sling

What was more disturbing was that they had short sling it for the final 3 feet which meant a sling around the chuck assembly. For a 3 foot move .....

But hey, that is a key reason I had it delivered vs buying a grizzly/pm machine and getting it at the border. warranty [emoji51]

Sent from my iPhone using Tapatalk

Here’s dabbler marshalling cats with my lathe. If you look close you can see the rebar and pinch bar through both lift points. We took the back chip shield off. Thanks again John for the huge help.

Attachments

In the shop I'll remove the chip tray and gantry it from the lifting holes on both sides....

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Interesting. I don't have a commercial stand & therefore also no bar holes. But when i saw them on another lathe I thought that is the slam dunk method to hoist. But it looks like the straps connections have to be further out to avoid pressing on the tray? (red line example) -is that what you are saying. Even on this other move pic it looks like the strap is deflecting off the box (green arrow), but maybe that wasn't loading mode.

Anyways, congrats on the new machine.

Anyways, congrats on the new machine.

Attachments

When most of the weight is being held on the headstock lift points it is acceptable to lift it using an eye bolt from the way's web. It is a judgement call. If I can use the lifting holes, I always will. In this case they did everything right! It is covered in older copies of 'The Riggers handbook'. (I don't have a newer one).

Last edited:

The straps were so far out to avoid the lead screw the motor and other protuberances. We had to adjust the straps after this was taken.Interesting. I don't have a commercial stand & therefore also no bar holes. But when i saw them on another lathe I thought that is the slam dunk method to hoist. But it looks like the straps connections have to be further out to avoid pressing on the tray? (red line example) -is that what you are saying. Even on this other move pic it looks like the strap is deflecting off the box (green arrow), but maybe that wasn't loading mode.

Anyways, congrats on the new machine.

RobinHood

Ultra Member

For big machines, Modern has spreader bars that they use to keep the slings from pinching / crushing protuberances like lead screws, chip pans, etc., if required. It keeps the slings parallel to clear the obstacles and then forms the triangle above and toward the hook.

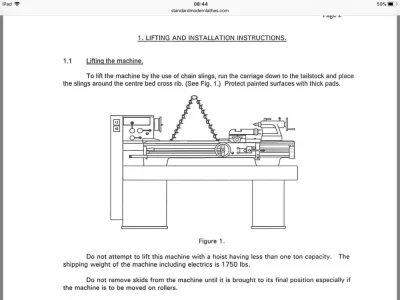

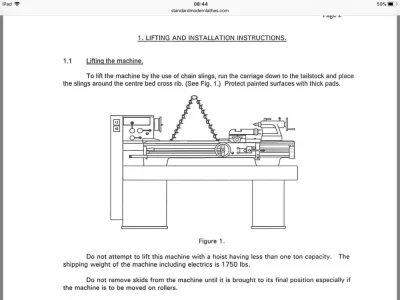

Here is a picture of how Standard Modern suggest to lift a 1340 lathe. One does lift it by the bed.

It does not have the lifting bar holes in the base like the bigger machines do. This method works very well. Use the carriage to adjust the balance and away you go.

Here is a picture of how Standard Modern suggest to lift a 1340 lathe. One does lift it by the bed.

It does not have the lifting bar holes in the base like the bigger machines do. This method works very well. Use the carriage to adjust the balance and away you go.

I'm starting to think there is a lot more to rigging than meets the eye. On another forum a guy was wanting to do that lifting 1340 type layout on a bigger lathe, but there was basically no open web close to the headstock and he couldn't or didn't want to remove the gap section. When they latched on to the bed opening closest to the headstock & eased it up, the c/g was not working to their advantage. I guess so much more weight on the headstock side (on that particular lathe) & it wanted to tilt that way.

The stand through holes look good to the eye and I'm sure they figured out the math beforehand. But the holes also seem low relative to the vertical c/g, meaning most of the lathe mass occurs above these holes so potential topside heavy situation? That's why I was wondering if the straps should be contacting the lathe a bit just to stabilize it from roll? Anyway, if a new machine comes my way, I want it to be the same outfit that pays if its rolling down the street haha.

The stand through holes look good to the eye and I'm sure they figured out the math beforehand. But the holes also seem low relative to the vertical c/g, meaning most of the lathe mass occurs above these holes so potential topside heavy situation? That's why I was wondering if the straps should be contacting the lathe a bit just to stabilize it from roll? Anyway, if a new machine comes my way, I want it to be the same outfit that pays if its rolling down the street haha.

Tom Kitta

Ultra Member

When I moved my old lathe I just put blocks of wood under the bed and moved it that way when forklift was there. Certainly the pictures show a major operation with multiple people present vs. me and my dad with two pry bars getting it off the trailer - and all my machines are at least 2x as heavy as that lathe. Maybe its time to get a lot of cases of beer & invite everyone here to a moving party once my new garage is ready?

BTW, what do you do once you remove the gap from the bed - how do you align it so it fits back perfectly?

BTW, what do you do once you remove the gap from the bed - how do you align it so it fits back perfectly?

When I bought my old Von wyck, the previous owner showed me the sweet spot to use a sling basket under the bed and picked it up with a front end loader . When I unloaded, it used the gantry and it balanced perfectly with one sling . One inch either way and it was a rodeo

Reference: the Von wyck was ~1600 lbs

Sent from my iPhone using Tapatalk

Reference: the Von wyck was ~1600 lbs

Sent from my iPhone using Tapatalk

When I moved my old lathe I just put blocks of wood under the bed and moved it that way when forklift was there. Certainly the pictures show a major operation with multiple people present vs. me and my dad with two pry bars getting it off the trailer - and all my machines are at least 2x as heavy as that lathe. Maybe its time to get a lot of cases of beer & invite everyone here to a moving party once my new garage is ready?

BTW, what do you do once you remove the gap from the bed - how do you align it so it fits back perfectly?

I think less is more. We had too many people. The rigger showed up with 3 guys. Plus me?’, John, the seller and one more buddy. Honestly it took longer and was harder than with two or three we had at the other end. Then I moved it the last 12 feet on my own and lowered down to the floor with pry bar and one plank at a time.

I've moved 5 machines over 1000 lbs all by myself: off a truck or trailer, over soft ground/gravel and into location. It is always much harder when there are more than 2 people helping. My biggest was over 3500 lbs. it just tool a little longer, but was not too hard.

Just saw this on Kijiji - https://www.kijiji.ca/v-tool-other/red-deer/metal-lathe/1338931540?enableSearchNavigationFlag=true

I'd love to know what this sells for......

From the stamp on the front, looks like 2001 model.

I'd love to know what this sells for......

From the stamp on the front, looks like 2001 model.

I'd venture any required parts could be sourced from Modern, its their sticker brand. Looks like general lack of TLC if the story is true. Hopefully it was moved properly. All it takes is some straps around the lead screw/power feed bars to mess things up. Somebody take that puppy home & get it off the dirt floor kennel.