Please go back & read my post #23 again because I think you are missing some key points.

OK, I've read ALL your posts several times again and tried my best to do two things.

1. Figure out what you are trying to tell me. In doing so, I have assumed that you do have a good point to make. You always do.

2. I have also tried to assume that where ever we fell off, that it is my fault that it happened.

After doing so, I conclude that you are trying desperately to explain something I already know. And at the same time, I am asking a question that you are not answering. Instead you are answering a question I did not intend to ask. Without any question, this is my fault for not being clear and for saying things that caused this derailing. At least that is my self analytical conclusion.

Please understand. While I am a newbie at using a full size knee mill, I am a very old hand at using a lathe.

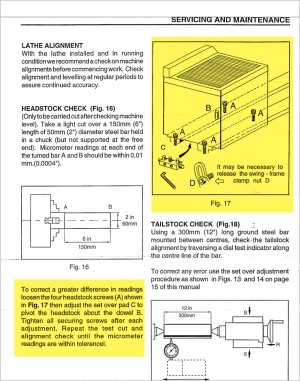

Peter - I know how to align the head on my lathe to the bed. I am NOT asking how to do that.

I confess I was critical of your MT5 mounted bar method. And this criticism probably did leave you to believe I didn't know how to align my head. This was my fault. And again, I apologize.

Perhaps worse, I wasn't clear at all about what I WAS asking. Again, my apologies. I will ask again shortly below and I'll try to be as clear as I possibly can.

What manuals? What lathe? It's critically important to define this from the outset. A lot of the older literature pertains to older lathes where the HS was essentially fixed to the bed. But you can't just jump to that conclusion & generalize.

I agree on all counts. For those who don't know how their own lathe is aligned, this is critical knowledge. You certainly can't align a head if you don't know how to do that on your own lathe.

However, I do know how mine is aligned. And again,

this is not my question.

This guy drives me batty but at ~11:00 another example of pivoting HS, Hermes lathe.

Frankly, he drives me batty too. That said, almost all youtube authors drive me batty. So I won't hold it against him or anyone else.

Nonetheless, it is a good video to that shows some of my issues and background.

At 5:50 he explains how his lathe is aligned using the lathe cabinet feet. That is the same method as mine uses.

Also, at 12:42 he explains how he uses cuts on a bar to evaluate his alignment. This is also the method that I use.

But please note that there are a few problems with his method. Hopefully, I can address those as I ask my question again more clearly.

------------------------------------------

So what is the question that I am I asking? Before I actually ask, let me make a few statements.

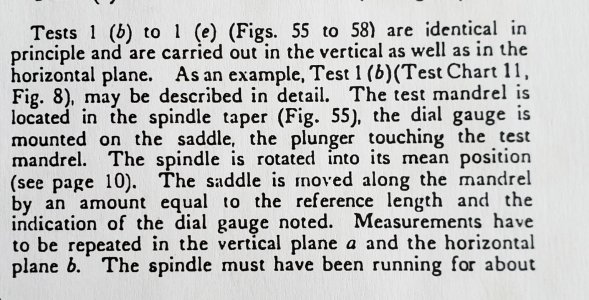

Many machinists take cuts on an unsupported test bar to test for the correct alignment of a lathe head to the lathe ways. That is the method used in the video you posted.

This is also my method and I don't want to change it. However, I do want to improve it. In fact, I want to improve on this method in two ways.

1. I want to use replaceable collars to avoid wasting a lot of material on my test bar.

2. I want to use a longer test bar to improve resolution.

These are two improvements that have some challenges buried in them. My questions address these challenges.

Question #1 - How do I attach replaceable aluminium collars to the test bar in a way that makes them: a) easy to change, b) does not introduce an interrupted cut for a fastener, c) does not weaken or reduce the rigidity of the test bar in any way, & d) minimizes any bias in the far end cut due to tool pressure during the cutting process.

Question #2 - What is the best way to compensate for the increased "droop" caused by the weight of a long test bar? I have assumed that a large diameter steel pipe had the highest resistance to bending under its own weight. I think this 2nd question is an ideal one for you

@PeterT because you love to do drawings that analyse geometry.

Further discussion:

Attaching a shouldered flange collar could be done with grub screws in the shoulder. But this makes the collars more difficult to make and requires more and bigger stock which is counterproductive to my goal of reducing the waste of good stock.

The collars could be glued on - but this would need to be removable glue to make them replaceable.

A double sided collet of some kind could be employed to grip the pipe and hold replaceable collets.

Permanent shoulders could be used and large aluminium washers (acting as replaceable collars) could be screwed to the permanent shoulders from the side.

The collars can be thin to reduce the machining required.

But my main focus at this point has been on the bar itself. I have found through experimental analysis that a 24" long 1-1/4 inch pipe bends about 1 thou under its own weight. I suppose that a 1-1/4" aluminium pipe might bend less due to a higher strength/weight ratio. But an aluminium pipe would also bend more than a steel one under tool pressure which might be worse.

Frankly, I'm not even convinced that longer is better anyway. I've never used a long one in the past and I've never seen anyone else using a longer one. So perhaps this is mostly a tail chasing game. Or are others just more scared of a long bar whipping around, or tool pressure deflection, or or or. To me, the question is simply not simple! If it were, I wouldn't be here asking about it!