In @Brent H , post on miss metric, I asked about potentially using a black pipe and two replaceable collars to align a lathe head to the lathe bed. I speculated that such a bar might save me from wasting an otherwise useful piece of bar.

@Brent H , @PeterT , @YYCHM, @YotaBota , & @Tom O have all provided input on Brent's thread so I have named them here so they can provide further input if they wish without hijacking Brent's thread.

The idea of using cheap black pipe is simply to make the bar stiff without adding unnecessary weight which might deflect and affect the alignment.

I will make the assumption here that others already know how to align a tailstock. This is not about that task. This is about aligning (or testing the alignment of) the spindle to the bed.

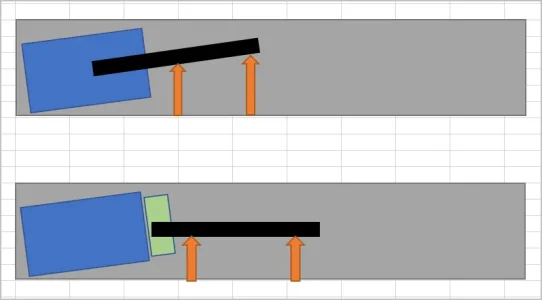

I believe said alignment requires a cut at both ends of a test bar. Ideally, the center section of the bar is of smaller OD than the ends so that the tool bit can move end to end without cutting the center. But this is not a requirement.

Such a bar is NOT mounted in centers. It can be mounted in the spindle taper or in jaws. In either case, a cut must be made at both ends to true the axis of the bar to the axis of the spindle. However, the extent to which the axis of the bed is misaligned with the axis of the spindle will affect the OD of the two ends. It is this difference that is used to test and to determine the alignment.

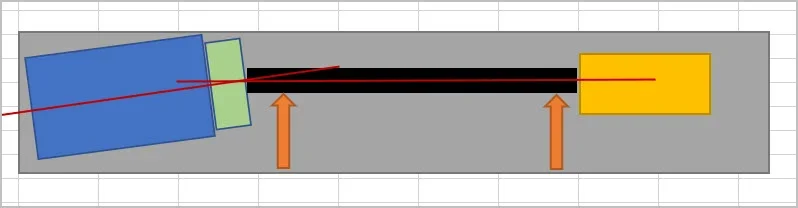

@PeterT prepared some drawings to demonstrate the evaluation and I have copied his post here.

I'm not sure I agree with Peter's post in total but usually I find that is because I didn't understand what he meant.

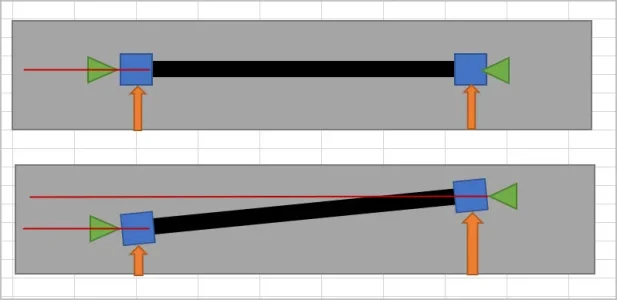

In my experience , the whole point of chucking the bar is to true it to the chuck axis. To do this cuts MUST be made. Said cuts will result in a perfect cylinder if the axis is aligned or a cone if they are not. Furthermore, measurements can be made at the tops and fronts of the bar to determine any angularity.

Ive always found it wasteful to use a solid bar because fresh cuts must be made each time the bar is used. @Brent H has apparently had the same experience. Hence my idea of a pipe and sleeves very similar to what @YotaBota suggests, but not mounted on centers. Again, to test head to bed alignment the bar must not be constrained to the tailstock.

I like the idea of locktite to hold the collars on, but I'm thinking screw on would be better at the far end and some kind of locking taper or even bolted connection at the near end. I'd like the replacement to be easy when they get too small.

@Brent H , @PeterT , @YYCHM, @YotaBota , & @Tom O have all provided input on Brent's thread so I have named them here so they can provide further input if they wish without hijacking Brent's thread.

The idea of using cheap black pipe is simply to make the bar stiff without adding unnecessary weight which might deflect and affect the alignment.

I will make the assumption here that others already know how to align a tailstock. This is not about that task. This is about aligning (or testing the alignment of) the spindle to the bed.

I believe said alignment requires a cut at both ends of a test bar. Ideally, the center section of the bar is of smaller OD than the ends so that the tool bit can move end to end without cutting the center. But this is not a requirement.

Such a bar is NOT mounted in centers. It can be mounted in the spindle taper or in jaws. In either case, a cut must be made at both ends to true the axis of the bar to the axis of the spindle. However, the extent to which the axis of the bed is misaligned with the axis of the spindle will affect the OD of the two ends. It is this difference that is used to test and to determine the alignment.

@PeterT prepared some drawings to demonstrate the evaluation and I have copied his post here.

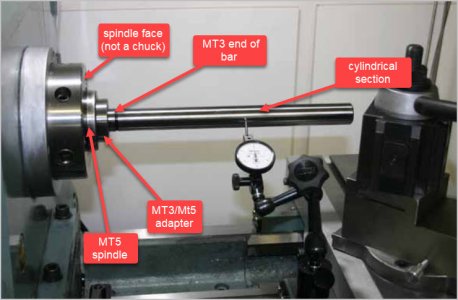

I'm talking about a shop made alignment dumb bell either from solid, or from something like a section of tubing plus separate ends to economize on material. All you need is Loctite to bond the ends. Tubing is actually desirable because it doesn't need to be cut (stress relief) & has plenty of rigidity for this application. Once you have end blanks either center drilled & slightly oversize OD ends, you mount between centers (not a chuck or collet) & take a skim cut over the OD. Preserve that infeed setting exactly, flip the bar & repeat skim cut on other side. They are now centered and parallel. Indicating on the HS side & comparing that to the TS side will indicate in/out & up/down of the TS center. No cutting is ever required beyond making the test bar.

To check spindle alignment relative to bed, the best method I know of is a precision MT taper / parallel bar. The one I bought is MT3 so I use my MT5/MT3 ground adapter that came with the lathe. You can also use this to stick in the tail stock MT socket & do some referencing there independent of the headstock. If you have a completely parallel test bar, it must be gripped by a chuck or something & you introduce potential errors.

I'm not sure I agree with Peter's post in total but usually I find that is because I didn't understand what he meant.

In my experience , the whole point of chucking the bar is to true it to the chuck axis. To do this cuts MUST be made. Said cuts will result in a perfect cylinder if the axis is aligned or a cone if they are not. Furthermore, measurements can be made at the tops and fronts of the bar to determine any angularity.

Ive always found it wasteful to use a solid bar because fresh cuts must be made each time the bar is used. @Brent H has apparently had the same experience. Hence my idea of a pipe and sleeves very similar to what @YotaBota suggests, but not mounted on centers. Again, to test head to bed alignment the bar must not be constrained to the tailstock.

I like the idea of locktite to hold the collars on, but I'm thinking screw on would be better at the far end and some kind of locking taper or even bolted connection at the near end. I'd like the replacement to be easy when they get too small.