Moving ahead.

Here is the setup I came up with for holding and centering the boiler blowdown valve body reversed in your 3 jaw chuck when there is virtually nothing to hold on to and your 3 jaw chuck is well used; the jaws are likely bell mouthed and perhaps even sprung. I am deliberately using the worst chuck which I have (but it has been the most faithful one over the decades). It is a 4" diameter KTM "Put" made in Poland and purchased in the early 1970's from Swiss Instruments here in Mississauga, Ontario. Swiss instruments, at the time, was having a one time sale on this brand of chuck and at the reduced price they were selling for - I think I paid $6. Canadian for this chuck and $8 for a larger 6" diameter one which I subsequently sold. But it did have its quality control issues as the jaws have tight spots on the scroll.,

I have given this chuck its fair share of use and abuse through sheer laziness, convenience and those times when conditions became pressing.

The interesting history here is that these chucks subsequently became the Bison line of chucks after the fall of communism.

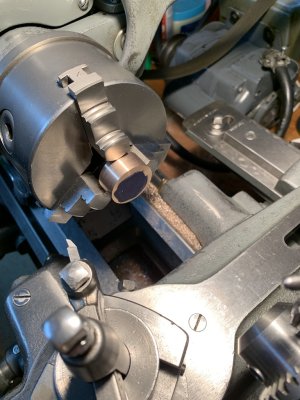

Anyway, the first thing I did was to produce a custom made 1" diameter aluminum spacer as a backing piece for the valve body half. The front face of the spacer is a machined spigot machined to 0.001" smaller in diameter than the 5/8" diameter recess in the half valve body and everything was turned concentric and faced flat all in one setting. The spacer was then reversed in the lathe chuck and machined to its final length and flat faced also.

The purpose of the spacer is to center the valve body piece in the jaws of the chuck, to steady it and to act as an end stop as the rear flat face of the spacer butts against the front body face of the chuck. I was a bit lucky here as the through hole in the chuck, although metric, was quite small, smaller than 1" as the diameter of the spacer has to be smaller than the 1-1/8" OD of the workpiece so everything worked out in that regard.

Now to the interesting part. As expected, due to the condition of the chuck, were the two end faces of the machined spacer going to be dead parallel? No, Not by a long shot. They showed a deviation of 2.5-3 thou. and I wanted the spacer to mike better than a thou. on overall thickness to virtually eliminate any wobble. So what to do?

Well, by measuring the spacer thickness with a micrometer every 90 degrees at the OD edge, one can determine the high spot. Mark this with a sharpie pen as shown in the first photo and re - chuck the spacer then bring your cutting tool right up to the face, lock the carriage and advance the cutting tool minutely to see where it scrapes the flat face while turning the lathe spindle by hand. If it does this at the sharpie mark as seen in the photo, all is well and proceed to reface the spacer end. If your cutting tool scrapes somewhere else, back off the jaws slightly, rotate the part in the jaws (say 45 degrees) and repeat the procedure over again until you find the sharpie high point mark.

Now the purists are all going to scream FOUL but it worked! After refacing, the spacer thickness miked 0.0004" deviation between all four readings. Maybe I was just lucky, (as I haven't seen the above described or mentioned before or anywhere else) but I think the procedure "averages out" all of the inaccuracies which the chuck has developed with time.

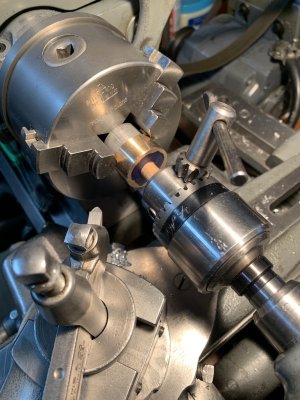

The final setup is as shown in the last photo. As seen, the chuck jaws are barely hanging on to the work and really are there only to provide a turning force. The wooden dowel held in the drill chuck held in the tailstock is there to provide a light seating force so the work can't go anywhere endwise.

I haven't done the actual turning down yet and very light cuts are warranted with a freshly sharpened cutting tool. As the building instructions say to form a radius at the end of the cut, I may have to do the final forming here by turning the lathe chuck by hand.

stay tuned.