-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Internal splines

- Thread starter Garyt

- Start date

Alu was just a guess on my part. Could be totally wrong.

Awaiting details from Gary…

I believe your right, the prop is aluminum, but that is bolted to the hub that contains all the prop pitch control jazz, I think a lot of the internals there are steel

I could be wrong as well, but I'm Fairley confident the mosquito (and most prop planes from that era on) have a variable pitch propeller, Wich has a bunch of stuff in the prop hub

Well I know of a quarter scale Merlin that was steel! LOL.

www.homemodelenginemachinist.com

www.homemodelenginemachinist.com

Quarter Scale Merlin V-12

The quarter scale Merlin's prop shaft is a scaled version of a design that's still in use today on full-size aircraft. It's externally splined, and its end is threaded for a castellated prop nut. In order to fit a propeller to this shaft I designed a splined hub that will become an integral part...

www.homemodelenginemachinist.com

www.homemodelenginemachinist.com

Tom Kitta

Ultra Member

Using EM for small internal splines is doable as I did similar for similar projects - but it does not work too well for something that is ... big.

One could see whatever one could do some kind of indexed broaching. But it would take a long time.

There must be a way to do these things faster in a home shop!

One could see whatever one could do some kind of indexed broaching. But it would take a long time.

There must be a way to do these things faster in a home shop!

Garyt

Well-Known Member

I am excited to see all of the interest in my question. No it will never leave the ground it is only for a test stand.

I am assuming that anyone interested would insist on making their own measurements. If nothing else it will include time with historical engines and aircraft. This is not a time sensitive thing we take years to get things done.

Gary

I am assuming that anyone interested would insist on making their own measurements. If nothing else it will include time with historical engines and aircraft. This is not a time sensitive thing we take years to get things done.

Gary

Using EM for small internal splines is doable as I did similar for similar projects - but it does not work too well for something that is ... big.

One could see whatever one could do some kind of indexed broaching. But it would take a long time.

There must be a way to do these things faster in a home shop!

I've never cut them but I think there potentially more to internal spline geometry form depending on the application. I am only guessing, but judging by pictures I'd be surprised if the spline slots were simple rectangular profile. This part is both a specialized & vintage so the geometry might be unique even by todays standards. I think splines might be analogous to gear tooth forms, they look roughly similar from across the room, but there is likely a lot of detail for them to function properly. Profile, clearance, stress relief fillets... all that good stuff.

I'm not quite sure what you mean my 'end milling' the internal profile. Do you mean roughing out the mass before finishing to the (typically curved) profile. Or a custom cutter with the curved spline profile? How would you get that tool in & out of (guessing) 4" bore x 6" length when EM must spinning perpendicular to the ID surface?

No it will never leave the ground it is only for a test stand.

You mean a 'running engine' test stand or a 'static display' stand?

I watched this last night he makes the clapper tooling and broach, the spline is at 16:00

Watched what?

I'm not quite sure what you mean my 'end milling' the internal profile. Do you mean roughing out the mass before finishing to the (typically curved) profile. Or a custom cutter with the curved spline profile? How would you get that tool in & out of (guessing) 4" bore x 6" length when EM must spinning perpendicular to the ID surface?

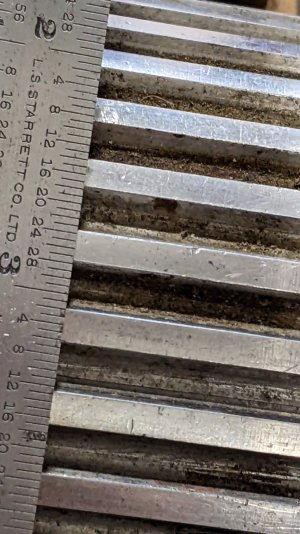

View attachment 29406

Yah I meant milling out the bulk of the material with larger than smaller EMs but only if the part is fairly thin. 1/2” maybe. That is not going to work on this long part.

Tom O

Ultra Member

Here’s a Lancaster running up.

I have some, and @Tom Kitta used to have some billets that big.