DPittman

Ultra Member

I have a Mesa tool also but it doesn't have two screw holes...just one center one. You simply flip insert or use left/right inserts. My tool is the 1/2" shank and I suspect @Susquatch tool is the larger version.Next up is still more options.

What tool to use? And which approach? It's almost a no brainer to use a regular threading tap and crank it in. BUT...... that isn't the point of this thread. Others have requested a single point thread demo so that's what this will be.

My goto threading tool Arthur Warner HSS Insert tool won't work on this job. The hole is too small. I have no idea what it's minimum thread hole is, but it's definitely bigger than this one!

View attachment 35507

View attachment 35508

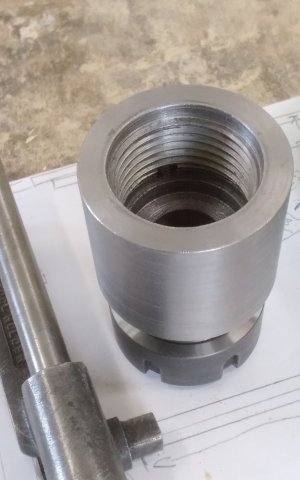

Next up is my MESA Carbide Insert Tool.

View attachment 35509

It isn't my favorite because it doesn't cut as well as sharp HSS does. But it does give the option of cutting at the front from inside out in reverse, or at the back outside in. You just choose which hole to put the screw in. Here I've chosen at the front. Time permitting, I'll do the other pin support in forward outside in.

View attachment 35510

And here you can see that it fits the hole.

View attachment 35511

Yes, it is on center, it just doesn't look like it. This is yet another time when a lathe tool height standard really shines. It's so easy to set tool heights with..... You don't even need the finger test with this setup. You just retract the cross slide and it either tries to tip the standard or it doesn't. This looks a bit high, but it's not. It's perfect.

View attachment 35516

I confess that describing this has generated an idea. This works sooooo well for upside down tools that I am thinking I want to make something similar for right side up. A standard with a notch in it. The tool either fits UNDER it, or it doesn't! Project 42p I think.....

The other options are a purchased threading tool or a hand made tool. Although I do have a threading tool that would work, it is extremely expensive and I don't really want to use it to cut sch40 pipe.

So that leaves this handground tool.

View attachment 35521

Yes, believe it or not, it does have a 60 deg thread profile. It just doesn't look like it in the photo cuz I don't have a nice sharp edge grinder.

View attachment 35522

Which to use?

I have square and round grooving and threading inserts. I love the tool but inserts are expensive and not readily available.