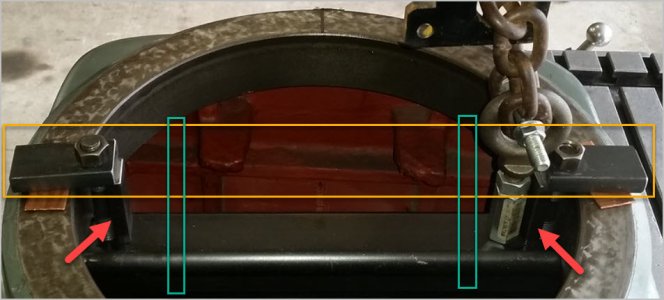

I have to load the base this mill, I'm guessing close to 2000lbs. It has to lifted high enough for a 23 inch tall trailer to back under it. I have removed the head and ram and cut a piece of 2" X 3" tube (1/4" wall) that extends 1 inch under each side to the ram bore. I welded a 1/2" nut inside the tube and a 1/2" eye bolt is threaded into it. The tube is held securely in the ram bore by 2 fabricated clamps on 1/2" studs. The crane boom is extended to the 1 ton setting. A short length of 5/16" chain is held to the crane with a 3/8" grade 5 through bolt. I have lifted it a couple of inches off the floor and it tips forward quite a bit so that the bottom pivots rearward and kind of wedges into the V of the engine crane's horizontal legs so if I lift it high enough to clear the crane legs I won't be able to set it down on the floor again.

This is the heaviest thing I've ever lifted with this crane and it's making me very nervous. I would appreciate some input from those of you who move heavy stuff around.

This is the heaviest thing I've ever lifted with this crane and it's making me very nervous. I would appreciate some input from those of you who move heavy stuff around.