Hi All,

Well, it started off very badly.

As I had the right (odd size commercial hardwood dowel of approx.1-3/32" dia) I said right, I will use that for the two cylinder pieces. So, I got to the stage shown in photo 30 when I started to measure things more closely and I discovered that this "round" dowel was really egg shaped and by a lot!

And, as well, after further calculations on how deep the two cylinder cutouts in the base block needed to be, the base block turned out to be too thin so scrap everything shown and start over again.

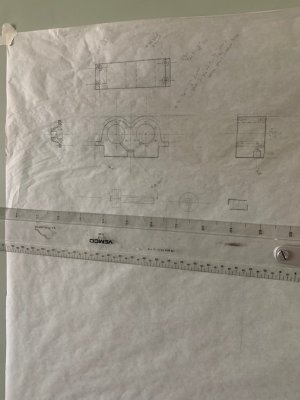

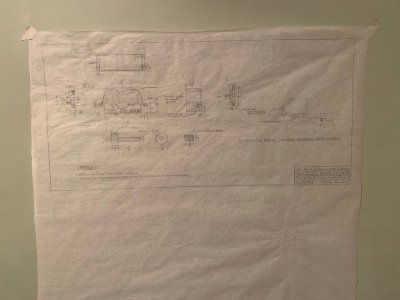

So, square up a new thicker base block and then carefully layout where the two cylinders needed to be (1-3/16" centre to centre with a 9/32" deep cutout). And, in addition, since everything needed to be centered lengthwise, this took a while.

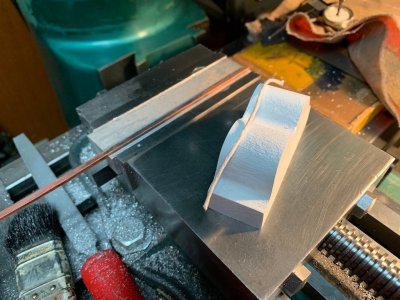

To rough out the two cylinder cutouts, I had a 1" dia. ball end mill and end mill holder. This was spotted on each cylinder centre line in turn as shown in photos 33, 34. Because the base block wood was just some unknown (a no, no) scrap wood which I had, I had to proceed very slowly and cautiously so as not to break the edges of the wood when the end mill entered and exited the piece. Some very minor splintering did occur but nothing which could not be fixed.

The only casualty; a lot of lost time doing everything the hard way again.

to be continued.

Well, it started off very badly.

As I had the right (odd size commercial hardwood dowel of approx.1-3/32" dia) I said right, I will use that for the two cylinder pieces. So, I got to the stage shown in photo 30 when I started to measure things more closely and I discovered that this "round" dowel was really egg shaped and by a lot!

And, as well, after further calculations on how deep the two cylinder cutouts in the base block needed to be, the base block turned out to be too thin so scrap everything shown and start over again.

So, square up a new thicker base block and then carefully layout where the two cylinders needed to be (1-3/16" centre to centre with a 9/32" deep cutout). And, in addition, since everything needed to be centered lengthwise, this took a while.

To rough out the two cylinder cutouts, I had a 1" dia. ball end mill and end mill holder. This was spotted on each cylinder centre line in turn as shown in photos 33, 34. Because the base block wood was just some unknown (a no, no) scrap wood which I had, I had to proceed very slowly and cautiously so as not to break the edges of the wood when the end mill entered and exited the piece. Some very minor splintering did occur but nothing which could not be fixed.

The only casualty; a lot of lost time doing everything the hard way again.

to be continued.

Attachments

-

30 Fools Rush In Where....jpeg125.3 KB · Views: 46

30 Fools Rush In Where....jpeg125.3 KB · Views: 46 -

31 Re-turning the Two Cylinder Pieces.jpeg167.3 KB · Views: 45

31 Re-turning the Two Cylinder Pieces.jpeg167.3 KB · Views: 45 -

32 Base Block and Cylinder Components.jpeg166.8 KB · Views: 40

32 Base Block and Cylinder Components.jpeg166.8 KB · Views: 40 -

33 Locating a Cylinder Recess in the Base Block.jpeg124.6 KB · Views: 33

33 Locating a Cylinder Recess in the Base Block.jpeg124.6 KB · Views: 33 -

34 After Ball End Mill Milling.jpeg134.3 KB · Views: 49

34 After Ball End Mill Milling.jpeg134.3 KB · Views: 49