Hi everyone,

I am new to the hobby metal working and I strumbled on your canadian forum for metal workers by luck of online searching

In these times, I kinda want kill my boredem and learn something new in my life with metal working while I can.

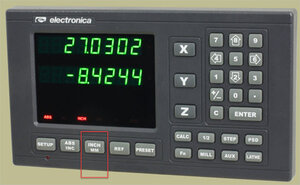

And hopefully, the mess is sorted out and I can find a decent metal lathe with all features I want plus being fully metric.

My thread about this search for context is in hobby machinist with same profile name.

I am new to the hobby metal working and I strumbled on your canadian forum for metal workers by luck of online searching

In these times, I kinda want kill my boredem and learn something new in my life with metal working while I can.

And hopefully, the mess is sorted out and I can find a decent metal lathe with all features I want plus being fully metric.

My thread about this search for context is in hobby machinist with same profile name.