Johnwa

Ultra Member

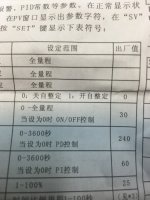

I've had some luck resetting the range on my controller. It looks like most variables are setable if you can make sense of the instructions.. From the factory mine had a range of 0-400C and one alarm set point. I've now set the upper range to 1250C and enabled the second alarm. The seller on aliexpress also said that 0-400 is the default but you can change it. I do wonder why the factory restricted the range though.

I've had less luck finding my thermocouple so I haven't been able to test it.

I've had less luck finding my thermocouple so I haven't been able to test it.