-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Hard vise jaws?

- Thread starter David

- Start date

Tool

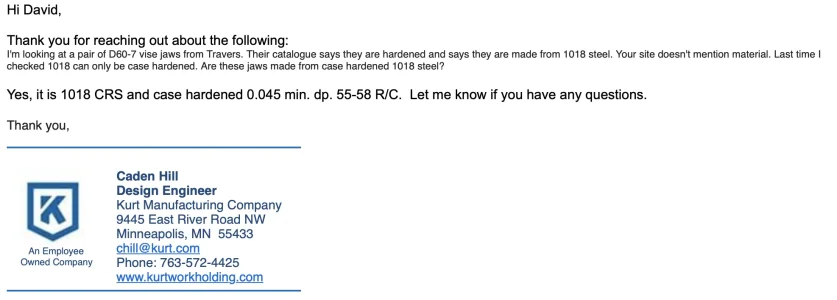

Case hardened?Saw this in an email from Travers:

Hard vise jaws from 1018 steel? That doesn't make sense to me.

View attachment 34519

Would have to be for any kind or durability.Case hardened?

I'm surprised they would use 1018. Even if case hardened, the core is dead soft, so if you tried to clamp a small part in the vise, and use excess pressure, you might dent the surface. Case hardened parts are great for sliding parts for wear resistance. But a better steel that needs to be cased is 8620, or 9310.

Snap Jaws use 4140 heat treated to 32Rc.

Snap Jaws use 4140 heat treated to 32Rc.

That's a pretty deep case depth.

That's what I thought too. They must have one heck of a good low-cost process for doing it this way vs using a hardenable steel.That's a pretty deep case depth.

It’s almost twice as deep as I could find in any case hardening references.It's difficult for me to believe they are case hardened to almost 50 thou. But if we take them at their word, go for it!

DPittman

Ultra Member

Yes it is but I still wonder if that would be hard enough with for jaws being that it is 1018.It’s almost twice as deep as I could find in any case hardening references.

Chipper5783

Super User

I have 3 Kurts (and just ordered another on the same sale that DavidR8 referenced), whatever the jaws are made out of, they are pretty hard and tough. The first Kurt I got the jaws were in tough shape, I gave them a little lick on the surface grinder - they are still hard. My vote is that Kurt knows what they are doing.