curmudgeon

(Steve)

I plan on placing a small order with Grizzly in the next few days. Does anyone on the South Island need anything? They ship by UPS, and I'm going to try self clearance to avoid the outrageous UPS brokerage fees.

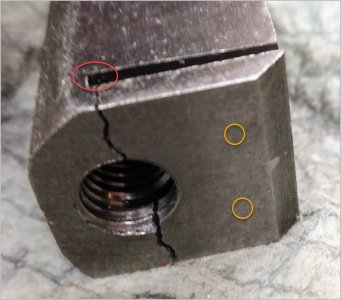

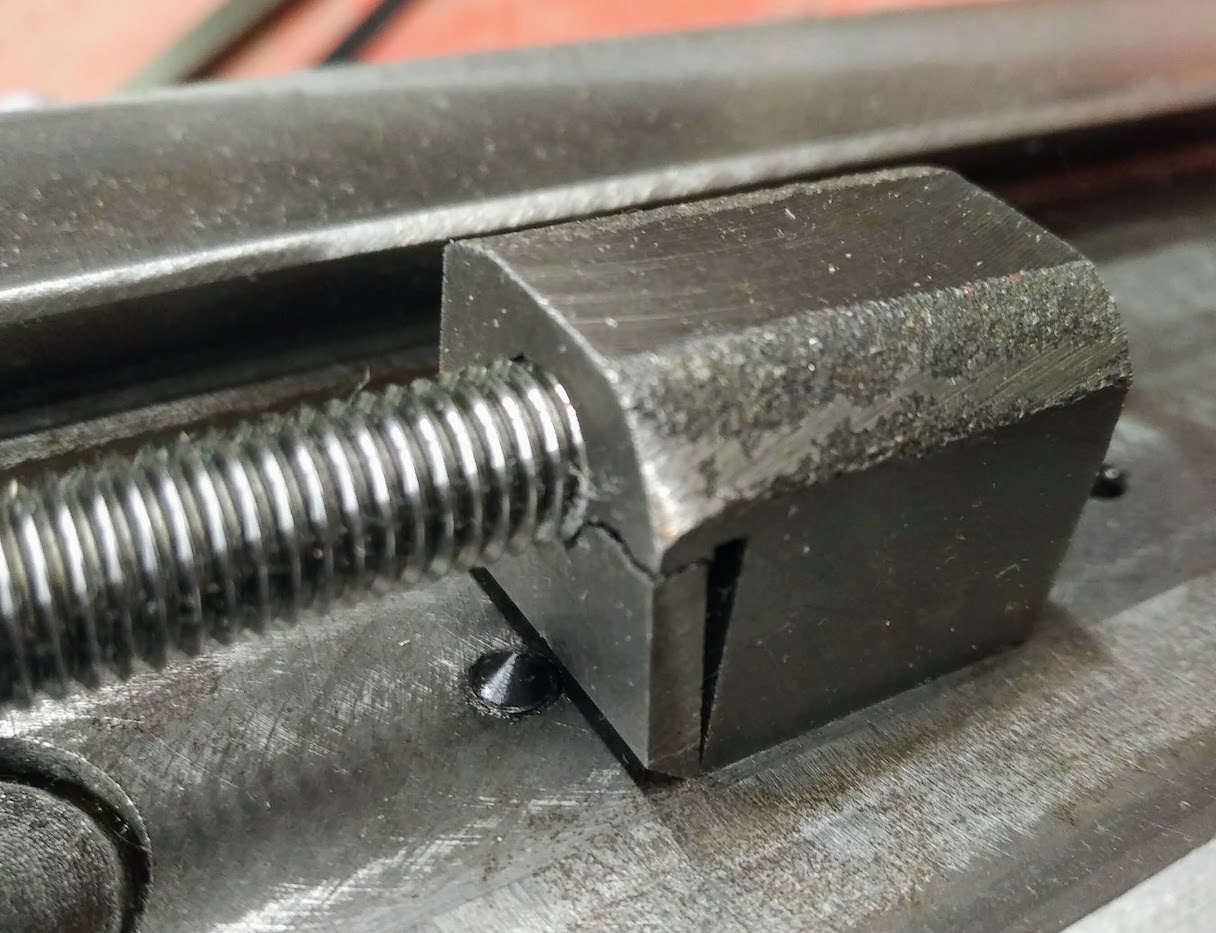

While replacing a ball-oiler on the cross slide of my G0602 10x22 lathe, I discovered that the cross slide leadscrew nut was broken; I recall the PO saying that the cross slide backlash used to be great but needed adjusting when I picked it up. Now I know why...

The King KC-1022ML parts diagram looks almost the same as the G0602, but it doesn't look like they stock it anymore, something about "Substitute Banks Item", otherwise I would have tried a Canadian supplier.

I considered trying to make one, but I'm not as brave, experienced, or as well equipped as @thestelster and his compound feed nut project - https://canadianhobbymetalworkers.com/threads/lathe-compound-feed-nut.6838

Anyway, if anyone on the South Island needs anything from Grizzly and wants to share shipping, lemme know.

While replacing a ball-oiler on the cross slide of my G0602 10x22 lathe, I discovered that the cross slide leadscrew nut was broken; I recall the PO saying that the cross slide backlash used to be great but needed adjusting when I picked it up. Now I know why...

The King KC-1022ML parts diagram looks almost the same as the G0602, but it doesn't look like they stock it anymore, something about "Substitute Banks Item", otherwise I would have tried a Canadian supplier.

I considered trying to make one, but I'm not as brave, experienced, or as well equipped as @thestelster and his compound feed nut project - https://canadianhobbymetalworkers.com/threads/lathe-compound-feed-nut.6838

Anyway, if anyone on the South Island needs anything from Grizzly and wants to share shipping, lemme know.