-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Granite Plate

- Thread starter PeterT

- Start date

Brent H

Ultra Member

I have only cleaned the surface plate with some acetone. For a bluing I have a 1/2” plate of glass to do the initial bluing test. That is usually pretty good.

Packing things up now so plate has gone into a drawer (left over from cabinetry) with a side of files

There is about 1/8” on top of the surface plate so that will get some bubble wrap and then a piece of plywood screwed across the top.

Packing things up now so plate has gone into a drawer (left over from cabinetry) with a side of files

There is about 1/8” on top of the surface plate so that will get some bubble wrap and then a piece of plywood screwed across the top.

After looking at used/new 'height' accessories I came to a few personal conclusions, maybe right, maybe wrong. In terms of scribing parts some vertical distance from the surface plate, I don't really see myself doing what is essentially layout work like that a ton, maybe occasionally. I have a scribe block & it just isn't super useful IMO. The scribe point needs to be registered to something, it doesn't readily accomodate DTI, no balled end main rod. So putting more effort modifying it doesn't seem as appealing.

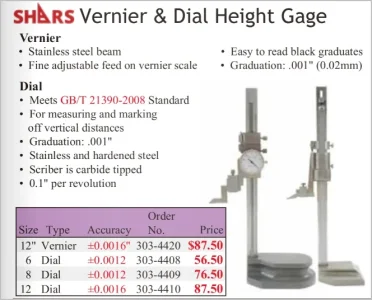

Measuring type surface height gages. I guess you zero reference, move to desired height, scribe a line. Or within reason contact the anvil on a part & read height. Some (but not all) allow replacing the scribe with a holder accessory for DTI. But now the main readout becomes kind of redundant because the DTI needs some master gage to reference off of, so it becomes a glorified levitation device. The dual beam style (digital or dial/digit) can get very spendy. The digital vernier style I'm guessing might be similar to same class calipers. Vernier style is not for my eyesight. The accuracy (when referenced & believable) for all these is +/- 0.001".

So for this particular purpose I took advantage of Black Friday & ordered a Shars 8" dial height gage. I'm not expecting a Mitutoyo but hopefully won't be shite & will serve this particular need. The scribe anvil is removable to accommodate included/shop made DTI/dial holder accessory. I'll keep you posted

Measuring type surface height gages. I guess you zero reference, move to desired height, scribe a line. Or within reason contact the anvil on a part & read height. Some (but not all) allow replacing the scribe with a holder accessory for DTI. But now the main readout becomes kind of redundant because the DTI needs some master gage to reference off of, so it becomes a glorified levitation device. The dual beam style (digital or dial/digit) can get very spendy. The digital vernier style I'm guessing might be similar to same class calipers. Vernier style is not for my eyesight. The accuracy (when referenced & believable) for all these is +/- 0.001".

So for this particular purpose I took advantage of Black Friday & ordered a Shars 8" dial height gage. I'm not expecting a Mitutoyo but hopefully won't be shite & will serve this particular need. The scribe anvil is removable to accommodate included/shop made DTI/dial holder accessory. I'll keep you posted

Attachments

For what I'll call surface height comparison when a DTI or plunger indicator is used, I'm considering this path. I already have a Noga arm (left), what they call a centering indicator which has a stem intended to be grasped in mill/lathe collet chuck. What about making a nice steel base which slides on surface plate, it has a hole to attach the holder. Noga also makes arms with threaded ends (right) which could go into a tapped hole, presumably the same kind of arm assembly that goes into a mag block. The head already accommodates DTI dovetail, dial stem & has micro-adjust thumbscrew all integrated in the head.

Fisso concept (gasp $$$$)

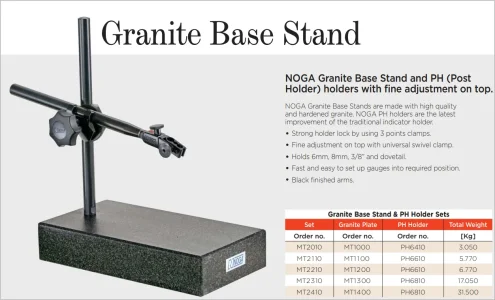

I'm not sure if these granite based stands are meant to slide on a granite surface plate or be standalone. Different kind of pillar post & arm, also available seperate.

Basically I'm suggesting a shop made base to this kind of assembly

Fisso concept (gasp $$$$)

I'm not sure if these granite based stands are meant to slide on a granite surface plate or be standalone. Different kind of pillar post & arm, also available seperate.

Basically I'm suggesting a shop made base to this kind of assembly

Attachments

@PeterT The height gauge you purchased is intended to do comparison measurements as well. If you order a DTI 'kit' instead of a bare DTI, it will include a bar that is intended to replace the scraper tool in your height gauge. This bar holds your DTI.

There is no need for an expensive additional base (unless you really want one).

There is no need for an expensive additional base (unless you really want one).

Squareness indicating might be a different animal again, or maybe integrated into above idea. I need to noodle this some more. I found a presumably shop made device very similar to what I was envisioning.

Base is turned on lathe so has circular profile, at least on one edge. He machined a contact ring profile. DTI is mounted, registered to a square, now ready to measure relative squareness. He removed material in the base & presumably lapped, something I was also wondering about.

Base is turned on lathe so has circular profile, at least on one edge. He machined a contact ring profile. DTI is mounted, registered to a square, now ready to measure relative squareness. He removed material in the base & presumably lapped, something I was also wondering about.

The shop made base was being mentioned if I use the Noga arm which has no base. The Noga granite base + arm combo is $$$ out of the question, I'm just showing a comparative picture. Replace granite with Peter lapped steel, I buy the arm seperate. Make sense?There is no need for an expensive additional base (unless you really want one).

Exactly, that was my plan with the Shars. Use it as-is for scribing mode. Or, replace scribe anvil with DTI fitting & use in comparator mode. I think it comes with DTI fitting but If not, easy enough to make an adapter.I understand you are thinking about making a base. I was trying to say that you might not need one at all - that you can use your height gauge instead.