If the user has the skills, and works with care, one can quite easily file to thousandths accuracy. Draw filing is as accurate as the user is... It applies directly, as a means of deburring parts too! A gentle pass with a single cut file will knock the sharp edges off, in a very controllable manner. Provided that the user understands the basic principles.

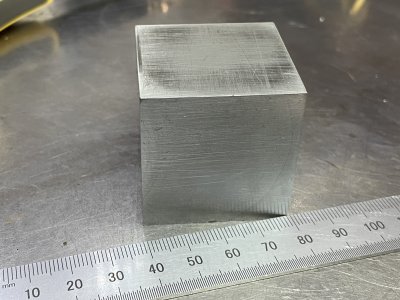

A fella I met had his grandfathers 'apprentice' project, which was required to be done before one advanced to using powered tools in his Machinist apprenticeship, which was a rectangle of steel plate, roughly half inch thick, in which three holes were drilled with a 1/2 inch drill, the only powered tool that was allowed in the making. The plate was filed externally, square and parallel.

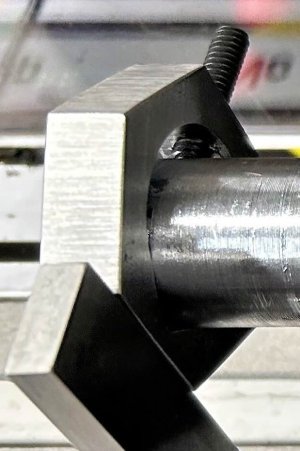

The three holes were then filed out to fit the 'plug', which was square from a side view, a triangle from the second angle, and round from the top view. The plug started out as an inch of round bar stock and inch in diameter.

Finished dimension of the round plug profile, was required to be 7/8 of an inch, and the holes had to allow a .0015" feeler gage to be freely inserted, but not a .0025 gage, in all holes, and in any orientation of the plug.

I used to demonstrate that it was not all that hard to file the center of the face of a bar, without touching the edges, by knowing your file (each is almost inevitably curved a wee bit concave on one side, and convex on the other) and knowing how to apply pressure with your fingers while holding it, flexing the face of the file as needed.

Files don't get enough respect, and most users don't take near the care storing and handling them, that they should get.