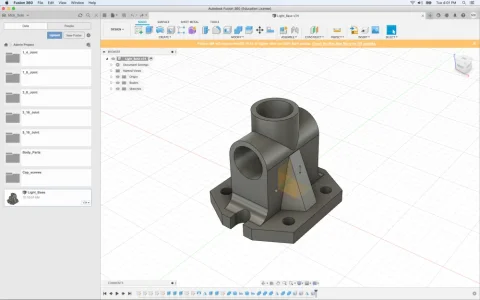

If a person doesn’t have or have access to CNC machines, is learning F360 still a useful shop skill?

My answer is YES. That pretty much defines my situation. Having digital drawing capability & especially 3D & assembly skills is so powerful. Plus, if you ever want to farm out a cnc job from your design, its only an email away. Its the cad file they want, they will have their own cam software specific to their machines. Like anything there is a learning curve & sounds like F360 has played some games lately with whats free & whats not. But seems like it still has a good following & lots of learning references out there. The next step up is a $ steep one to industrial software that pretty much do the same thing at a hobby level.