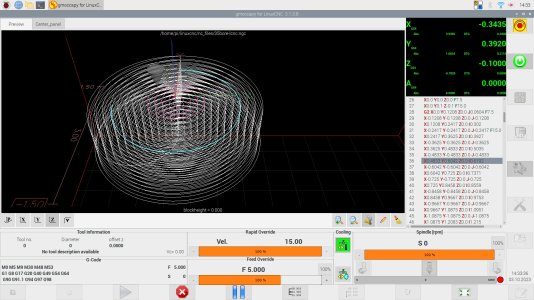

Interesting. When I tried the C code Jon Elson provided for using IJ parameters instead of R parameters LinuxCNC complained that the ending point was different from the starting point. My Lazarus version of his program wasn't any better. Never did figure out why.@jcdammeyer , here is a copy of the GCode Generated by Centriod's Intercon conversational language to compare.

I'll try running yours later today and see what happens. If it works maybe it will provide the clue as to why mine won't work. I haven't checked what MACH generates. My AlibreCAM creates short line segments; neither R or IJ path motion which is really bad IMHO.